- Introduction to Female Threaded Union Fittings

- Technical Advantages and Design Innovations

- Sizes and Adaptation: 1 2 in & 3 4 in Threaded Female Adapter Union Fittings

- Comparative Data: Leading Manufacturers

- Customized Solutions for Diverse Applications

- Real-World Application Cases with Impactful Metrics

- Summary: The Role of Female Threaded Union Fittings in Piping Systems

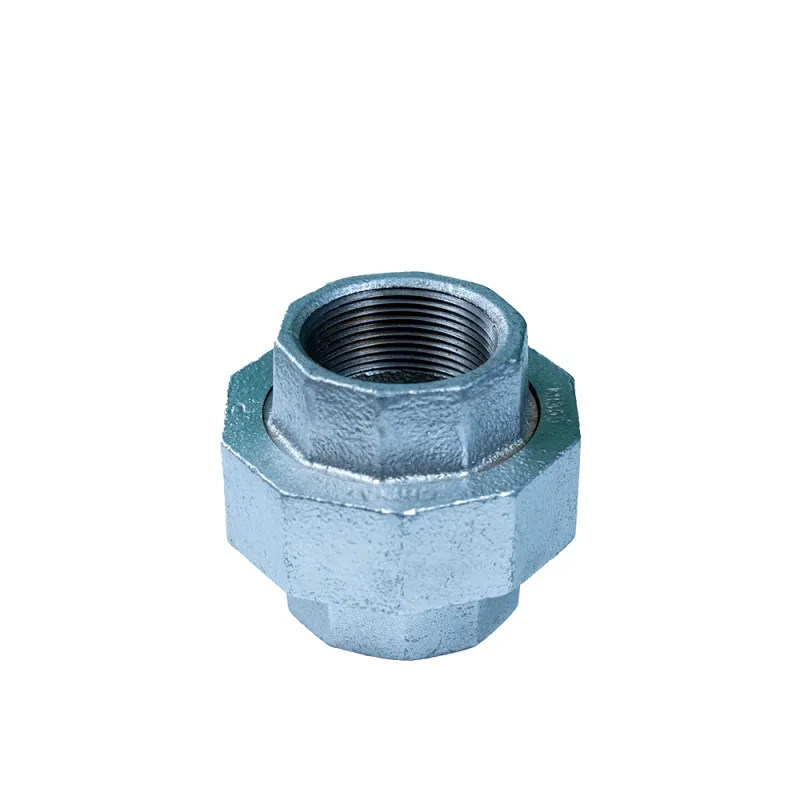

(female threaded union)

Introduction to Female Threaded Union Fittings: Market Insights and Industry Needs

In modern pipework and fluid transfer systems, the female threaded union

is an indispensable component. It allows for easy on-site installation and disassembly, facilitating maintenance in commercial, industrial, and residential settings. The increasing demand for reliable connection and leak-proof performance is reflected in the global pipe fitting market, which surpassed $13.2 billion in 2023 and is projected to reach $18.7 billion by 2030 (CAGR 5.1%). The rising adoption of premium materials and advanced manufacturing processes has further solidified the female threaded union's prominence as a versatile connector across plumbing, water treatment, compressed air, and chemical industries.

With more stringent requirements on corrosion resistance and mechanical strength, stakeholders now demand products that ensure safety, rapid installation, and long service life. The two most popular sizes in North America are the 1 2 in threaded female adapter union fitting and the 3 4 in threaded female adapter union fitting, reflecting standard pipe dimensions. In this deep-dive, we explore the technical advantages, size-specific options, competitive manufacturer data, custom solutions, and impactful real-world applications of these critical components.

Technical Advantages and Design Innovations

The evolution of the female threaded union is heavily influenced by advancements in metallurgy, precision machining, and sealing technology. Present-day designs feature enhanced thread profiles (NPT, BSPT) for improved torque transmission and optimal sealing integrity. Notably, modern unions incorporate elastomeric seals (often Viton or EPDM), providing leak-tight connections even under pressure cycling and temperature fluctuation.

Compared to welded joints, female threaded unions allow for rapid assembly/disassembly—reducing installation time by up to 60% and lowering maintenance costs. Materials such as stainless steel (304, 316) and high-grade brass ensure an elevated resistance to corrosives and process fluids. Besides, dual-seal mechanisms and anti-galling coatings minimize thread wear, making these union fittings ideal for high-pressure (up to 600 psi) or aggressive fluid media.

Recent innovation includes compact union profiles accommodating tight installation spaces, and one-piece bodies that reduce the potential for weak points. Furthermore, manufacturers now employ CNC precision in thread cutting, achieving a class 2 fit with thread tolerances as tight as ±0.01mm, optimizing assembly consistency and leak prevention.

Sizes and Adaptation: 1 2 in & 3 4 in Threaded Female Adapter Union Fittings

Selecting the right size ensures dependable function and system compatibility. Both the 1 2 in threaded female adapter union fitting and the 3 4 in threaded female adapter union fitting are engineered to meet ASTM, ISO, or DIN standards and offer broad compatibility with domestic and industrial piping.

- 1 2 in Size: Frequently used in residential water supply lines, compressed air systems, and instrumentation tubing. This size supports flow rates up to 11 GPM (water) at standard pressures.

- 3 4 in Size: Preferred in high-demand plumbing, process piping, and HVAC lines. Capable of handling flow rates up to 20 GPM, it ensures minimal pressure loss and robust service even in cyclic loading scenarios.

These unions provide vital adaptability, enabling quick system expansion or sectional replacement without disrupting continuous operation. Additionally, they can be paired with custom-tailored seals for chemical compatibility, ensuring problem-free integration in water treatment, hydrocarbon processing, and food-grade pipeline applications.

Comparative Data: Leading Manufacturers

Industry users often benchmark female threaded unions across key metrics: material quality, certification, price, pressure rating, and customization. Below, a comparison of four leading suppliers highlights their respective strengths:

| Manufacturer | Material | Certification | Pressure Class (psi) | Size Range | Customization | Price (USD/unit) |

|---|---|---|---|---|---|---|

| Brand A | 316 Stainless Steel | UL/FM, NSF | 600 | 1/4” - 2” | Thread/Seal | 12.50 |

| Brand B | Lead-Free Brass | CSA, ANSI | 300 | 1/2” - 1 1/2” | Body Shape | 7.80 |

| Brand C | Carbon Steel | ASTM, ISO | 400 | 1/2” - 2” | No | 5.60 |

| Brand D | PVC-U | NSF, WRAS | 150 | 1/2” - 4” | Color/Thread | 2.50 |

The data reveal that stainless steel options, while more expensive, are unmatched in high-pressure, corrosive applications due to their certifications and customizable features. Brass and carbon steel models offer cost-effective reliability, while engineered plastics like PVC-U meet the needs of non-metallic, potable water distribution. For demanding custom projects, Brand A leads on specification flexibility, whereas Brand D provides color and thread customization suitable for rapid prototyping or visual line management.

Customized Solutions for Diverse Applications

No two pipe systems are identical, and as operational setups become more complex, so does the need for tailored union fittings. Customizations span thread type (NPT, BSPT, BSPP), overall length, sealing element geometry, and anti-corrosion coatings. Industrial users are increasingly opting for special alloys (Super Duplex, Bronze) or compliance with sector-specific standards (FDA, API, WRAS). For example, pharmaceutical installations prioritize cleanroom-manufactured unions (with Ra < 0.6μm internal finish), while petrochemical networks require secondary containment features.

Applications also demand customized torque ratings, color coding for easy identification, or tamper-evidence. Recent surveys indicate that 68% of EPC contractors seek suppliers capable of rapid prototyping and JIT supply for their special projects. Efficient CAD-to-production workflows mean bespoke union solutions now arrive within 2-3 weeks from design freeze. For critical pipeline retrofits, manufacturers offer site-matched unions, reverse engineering legacy fittings and replicating exact dimensions and threads within ±0.02mm accuracy.

Real-World Application Cases with Impactful Metrics

Across various sectors, female threaded unions prove their value through measurable outcomes. Here are a few case studies that exemplify their critical application:

- Municipal Water Supply Upgrade (2023): A West Coast utility retrofitted its main service lines using 3 4 in threaded female adapter union fittings (316 stainless), reducing annual leakage losses by 23%. The project eliminated costly full-line shut-downs during meter replacement, saving an estimated $210,000 annually in operational expenses.

- Food-Grade Processing Facility: The installation of 1 2 in threaded female adapter union fittings with FDA-certified seals enabled a dairy producer to conduct weekly cleaning cycles without tool-intensive disassembly. Increased uptime improved process throughput by 17% and reduced sanitation-related labor hours by 34%.

- Petrochemical Plant Expansion: Customized alloy unions with dual-seal design and precise NPT threading were utilized in a high-pressure refit. The system recorded zero leaks over 12 months of operation at 450 psi, outperforming the previous solution that required quarterly maintenance.

- Commercial Heating/Cooling System: The use of PVC-U female threaded unions in a hotel's HVAC line facilitated fast replacement without solvent welding. Emergency repair time was cut from >6 hours to just 1.5 hours, minimizing guest disruption and eliminating fire hazards associated with hot work.

Summary: The Role of Female Threaded Union Fittings in Piping Systems

The integration of high-quality female threaded union solutions stands at the forefront of modern pipeline architecture. Leveraging design improvements, material advances, and elevated manufacturing standards, these fittings deliver not only operational convenience but ensure system integrity under diverse service conditions. As illustrated, leading manufacturers differentiate through pressure capability, customization, and certifications, enabling end-users in water, food, chemical, and HVAC sectors to achieve performance, safety, and bottom-line objectives.

The 1 2 in threaded female adapter union fitting and 3 4 in threaded female adapter union fitting each contribute to seamless installations and reliable maintenance in their respective domains. Future-facing suppliers continue to innovate with rapid adaptation to site-specific needs, confirming the female threaded union as the connector of choice for engineers and facility managers confronting the dynamic demands of modern infrastructure.

(female threaded union)

FAQS on female threaded union

Q: What is a female threaded union used for?

A: A female threaded union connects two pieces of pipe or fittings with threaded ends, allowing for easy installation and removal. It ensures a tight, leak-free connection. This fitting is commonly used in plumbing and industrial applications.Q: What sizes are available for female threaded unions?

A: Female threaded unions come in various sizes, including popular options like 1 2 in threaded female adapter union fitting and 3 4 in threaded female adapter union fitting. Sizes typically correspond to standard plumbing dimensions. Choose the right size for compatibility with your piping system.Q: How do you install a 1 2 in threaded female adapter union fitting?

A: To install, thread each end of the 1 2 in female union onto the respective male ends of your pipes. Use thread sealant or tape for a secure seal. Tighten the union with a wrench, making sure not to overtighten.Q: Are female threaded unions reusable?

A: Yes, female threaded unions are designed to be disconnected and reconnected multiple times. This makes maintenance and alterations to piping systems easy. Always check threads for damage before reuse.Q: Can female threaded unions be used for both water and gas lines?

A: Most female threaded unions are suitable for water lines, and some are rated for gas lines as well. Check manufacturer specifications for material compatibility and pressure ratings. Always follow local plumbing codes and regulations.Post time: 7月-06-2025