Understanding Ward Malleable Iron Fittings: A Pillar of Industrial Connectivity

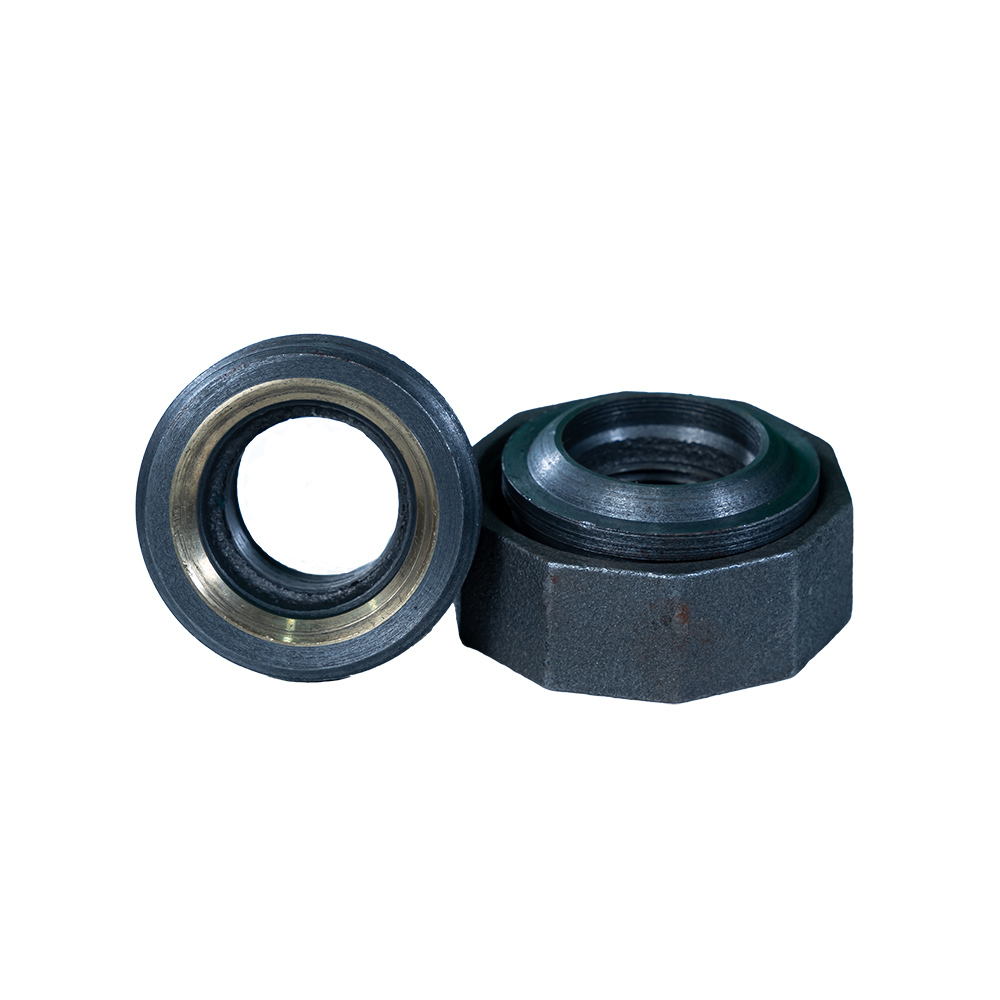

In the intricate world of industrial fluid transfer and piping systems, the choice of fittings dictates not only operational efficiency but also long-term reliability and safety. Among the myriad options available, ward malleable iron fittings stand out as a foundational component, revered for their exceptional ductility, strength, and remarkable resistance to shock and vibration. Unlike their brittle grey cast iron counterparts, malleable iron undergoes a specialized heat treatment process, transforming its microstructure to impart superior mechanical properties, making it an ideal material for high-pressure and high-stress applications across diverse sectors. These fittings, including specific products like our Union with Brass Seat Threading Fitting, are designed to create secure, leak-proof connections in critical infrastructure, ranging from petrochemical plants and large-scale manufacturing facilities to sophisticated municipal water management systems and advanced HVAC installations. Their enduring popularity is rooted in a combination of metallurgical excellence, precise manufacturing, and an inherent versatility that allows them to seamlessly integrate into complex piping networks, providing robust solutions where performance and longevity are paramount. The term "ward malleable" specifically refers to a historical standard or type of malleable iron known for its robust qualities, often associated with high-grade, durable fittings. This comprehensive exploration delves into the technical nuances, application spectrum, and unparalleled advantages of these essential industrial components, providing B2B decision-makers and technical professionals with the insights necessary to make informed choices for their most demanding projects. We will cover everything from their detailed manufacturing processes and stringent quality control protocols to their real-world application benefits, ensuring a holistic understanding of their value proposition in today's demanding industrial landscape.

Navigating Industry Trends and Market Dynamics for Robust Piping Solutions

The global industrial piping and fittings market is currently experiencing dynamic shifts, driven by escalating demand from critical infrastructure projects, a renewed focus on energy efficiency, and stringent environmental regulations. Within this evolving landscape, the role of ward malleable iron fittings continues to expand, benefiting from their proven reliability and adaptability in harsh operating conditions. Industry trends indicate a consistent growth trajectory for sectors reliant on durable pipe connections, such as oil and gas, chemical processing, water and wastewater treatment, and advanced manufacturing. For instance, the global industrial pipe fittings market size was valued at approximately USD 20.3 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 5.1% from 2023 to 2030, according to Grand View Research, driven by significant infrastructure development in emerging economies and the modernization of aging facilities in developed nations. Furthermore, the increasing complexity of industrial processes necessitates fittings that can withstand higher pressures, extreme temperatures, and corrosive media, areas where malleable iron excels. Innovations in material science, surface treatments, and digital manufacturing (such as advanced CNC machining for improved precision on elements like a black iron reducing tee) are further enhancing the performance envelope of these fittings, pushing the boundaries of what is achievable in terms of longevity and operational safety. Manufacturers are increasingly investing in automation and advanced quality control systems to meet the rising demands for consistency and defect-free products, ensuring that every black iron union provides an unyielding connection while minimizing the risk of system failures. This market evolution underscores the importance of selecting fittings that not only meet current technical specifications but also offer resilience against future operational challenges and regulatory changes. The shift towards sustainable practices also favors materials with long lifecycles and high recyclability, attributes inherent to iron-based components, positioning high-quality malleable iron solutions as a cornerstone for future-proof industrial systems and supporting industries like fire protection and HVAC that demand uncompromising reliability and adherence to strict safety standards.

Technical Parameters and Specifications of Ward Malleable Iron Fittings

The superior performance of ward malleable iron fittings is intrinsically linked to their precise technical specifications and metallurgical properties. These fittings are manufactured from white cast iron that undergoes an extensive annealing process, transforming the brittle carbide structure into ductile graphite nodules or temper carbon, resulting in a material with excellent tensile strength, elongation, and impact resistance. Typical material grades adhere to international standards such as ASTM A197 for malleable iron castings and ISO 5922 / EN 1562 for malleable cast iron, ensuring global interchangeability and performance consistency. For instance, common mechanical properties for ferritic Blackheart malleable iron include a minimum tensile strength of 310 MPa (45,000 psi), a minimum yield strength of 207 MPa (30,000 psi), and an elongation of at least 10%. These properties are significantly superior to those of grey cast iron, ensuring the fittings can withstand substantial mechanical stress, vibration, and thermal cycling without fracturing, a critical advantage in dynamic industrial environments. Pressure ratings typically conform to ANSI B16.3 (for threaded fittings) or ISO 7-1 (for pipe threads), with Class 150 fittings rated for up to 150 PSI (10 bar) for steam and water and often higher for non-shock cold water applications, while Class 300 fittings offer even greater pressure capabilities. Temperature limits generally range from -20°C to 232°C (-4°F to 450°F), making them suitable for a wide array of process fluids and environmental conditions. Threading specifications commonly include NPT (National Pipe Taper) for North American markets and BSPT (British Standard Pipe Taper) or BSPP (British Standard Parallel Pipe) for European and Asian markets, ensuring global compatibility for a black iron union fitting. Furthermore, the surface finish can range from black (self-color) for general indoor use to hot-dip galvanized, with galvanization providing enhanced corrosion resistance due to a robust zinc coating, significantly extending the service life in corrosive or outdoor environments. The precise dimensional tolerances, governed by standards like ANSI B16.3 or EN 10242, ensure that fittings like a black iron union offer consistent fit and interchangeability, simplifying installation and maintenance procedures for complex piping systems while guaranteeing leak-proof connections for optimal system integrity and efficiency.

Key Specifications Table: Ward Malleable Iron Fittings

| Parameter | Typical Value / Standard | Description / Benefit |

|---|---|---|

| Material Composition | ASTM A197 Malleable Iron (e.g., Fe, 2.0-2.6% C, 1.0-1.6% Si, 0.3-0.8% Mn, <0.15% P, <0.15% S) | High-grade white cast iron annealed for superior ductility and strength, critical for shock resistance. |

| Tensile Strength | Min. 310 MPa (45,000 psi) | Ability to withstand significant pulling or stretching forces before fracture, ensuring structural integrity. |

| Yield Strength | Min. 207 MPa (30,000 psi) | Resistance to permanent deformation when subjected to stress, crucial for maintaining shape under load. |

| Elongation | Min. 10% (Ferritic Grade) | Indicates ductility and capacity to deform plastically without breaking, absorbing system stresses. |

| Hardness (Brinell) | 120-170 HB | Resistance to indentation and wear, contributing to longevity in abrasive environments. |

| Pressure Rating | Class 150/300 (up to 10 Bar for 150, 20 Bar for 300) | Suitable for various fluid handling pressures as per ANSI B16.3 and EN 10242, ensuring safety margin. |

| Temperature Range | -20°C to 232°C (-4°F to 450°F) | Broad applicability across different thermal conditions, resisting thermal shock. |

| Threading Standards | NPT, BSPT, BSPP (ISO 7-1, ASME B1.20.1) | Ensures global compatibility and leak-proof connections when properly installed. |

| Sizes Available | 1/8" to 6" (DN6 to DN150), larger on custom order | Accommodates a wide range of pipe diameters and flow requirements. |

| Surface Finish | Black or Hot-Dip Galvanized (ASTM A153/A123 compliant) | Corrosion protection for extended lifespan in various environments, from indoor to outdoor. |

The Rigorous Manufacturing Process of Ward Malleable Iron Fittings

The production of high-quality ward malleable iron fittings is a meticulously controlled multi-stage process, beginning with raw material selection and culminating in a robust, precisely threaded product. It commences with the careful selection of raw materials, primarily steel scrap and pig iron, which are melted in electric arc or induction furnaces. This melting process is crucial, as it controls the precise chemical composition (especially carbon and silicon content) required to produce white cast iron—a brittle material characterized by its high carbon content in the form of cementite (iron carbide). White iron is chosen specifically because its carbon is chemically combined with iron, making it amenable to transformation. Once cast into the desired shape using advanced molding techniques (e.g., green sand or shell molding), these white iron castings are then subjected to the crucial annealing process. This heat treatment, performed in specialized furnaces with controlled atmospheres, involves heating the castings to high temperatures (typically 850°C to 950°C or 1560°F to 1740°F) for extended periods, followed by controlled cooling. During this annealing cycle, the hard and brittle cementite decomposes into soft, ductile graphite nodules (often referred to as temper carbon) and ferrite, transforming the material into malleable iron with a ferritic microstructure. This transformation significantly enhances the ductility, impact strength, and machinability of the fittings, moving them from brittle to tough. After annealing, the fittings undergo meticulous finishing operations. This includes descaling (removing surface oxides), grinding, and precision machining, often utilizing advanced CNC (Computer Numerical Control) equipment to ensure exact dimensional accuracy and thread integrity. For products like a black iron reducing tee, maintaining precise angles, consistent wall thickness, and seamless flow paths is critical for optimal performance and minimal pressure drop. Threads are meticulously cut or rolled to meet international standards such as NPT, BSPT, or BSPP, ensuring perfect compatibility with corresponding pipes and enabling leak-proof, reliable connections. Many fittings then proceed to hot-dip galvanization, where they are immersed in molten zinc to create a protective, corrosion-resistant coating that adheres metallurgically to the iron surface, significantly extending their service life in harsh environments by providing a sacrificial layer against rust. Throughout every stage, stringent quality control measures are implemented, from spectral analysis of molten metal to hydrostatic pressure testing, non-destructive testing (NDT) methods like magnetic particle inspection, and comprehensive dimensional inspections, guaranteeing that each ward malleable iron fitting adheres to globally recognized standards like ISO, ANSI, and ASTM, promising exceptional performance and reliability, and ensuring a predictable service life measured in decades.

Figure 1: Depiction of the precision casting process critical for producing high-quality ward malleable iron fittings, ensuring initial dimensional accuracy and material consistency.

Advanced Manufacturing and Uncompromising Quality Assurance

Beyond the fundamental production steps, the true distinction of premium ward malleable iron fittings lies in the advanced manufacturing techniques and the rigorous, multi-layered quality assurance protocols implemented throughout their creation. Modern foundries leverage sophisticated automation, including robotic handling systems and automated pouring, to ensure consistent quality and reduce human error during the casting phase, leading to highly uniform castings. Induction melting furnaces, for instance, offer superior control over melt chemistry and temperature, leading to more homogeneous microstructures in the white iron castings before annealing, which is crucial for optimal material transformation. The annealing process itself is precisely controlled using advanced thermal profiling systems and continuous monitoring to guarantee complete transformation of brittle cementite into ductile graphite, which is subsequently verified through metallographic examinations, where samples are viewed under a microscope, and hardness testing (e.g., Brinell hardness) on representative samples from each batch. Following heat treatment, precision CNC machining plays a pivotal role in achieving the exacting dimensional tolerances and superior thread quality essential for reliable connections. Every thread on a black iron union fitting, for example, is subject to strict gauge checks (using Go/No-Go gauges) to ensure perfect fit and seal, minimizing the risk of leaks in operational systems and facilitating easy installation. For galvanized fittings, the hot-dip galvanization process is meticulously monitored for coating thickness, adhesion, and uniformity, adhering strictly to international standards like ASTM A153/A123. Quality assurance extends to 100% hydrostatic pressure testing, where fittings are subjected to internal pressures significantly higher than their rated working pressure (e.g., 500 PSI for Class 150 fittings) to verify structural integrity and leak-tightness under stress. Non-destructive testing (NDT) methods, such as magnetic particle inspection for surface defects or eddy current testing for internal flaws, are also employed on a statistical basis to further bolster reliability and detect any imperfections that might compromise performance. Compliance with international standards such as ISO 9001 for quality management systems, ANSI B16.3 for dimensional and material specifications, and EN 10242 for thread and material properties is not merely a certification but a fundamental commitment to excellence that permeates every stage of the manufacturing process, from raw material inspection to final product packaging, ensuring that each ward malleable iron fitting delivers consistent, dependable performance in the most challenging industrial applications, directly impacting the longevity and safety of complex piping systems.

Versatile Application Scenarios and Profound Industry Benefits

The inherent strength, ductility, and reliability of ward malleable iron fittings make them indispensable across a wide spectrum of industrial and commercial applications, providing robust solutions where other materials might falter. In the petrochemical industry, for instance, these fittings are crucial for conveying hydrocarbons, natural gas, and various chemicals under moderate to high pressures and fluctuating temperatures. Their ability to resist shock and vibration, a direct consequence of their unique microstructure, is paramount in these dynamic environments, preventing catastrophic failures that could lead to environmental hazards, production downtime, or significant safety risks. Similarly, in the metallurgical sector, especially in facilities dealing with water, air, or steam lines, malleable iron fittings offer the necessary durability to withstand the demanding conditions, including thermal expansion and contraction, common in high-temperature processing. For municipal and industrial water supply and drainage systems, ward malleable iron fittings are a standard choice due to their proven longevity and resistance to internal corrosion (especially galvanized variants), ensuring clean water delivery and efficient waste removal over decades with minimal maintenance. Their robust nature also makes them ideal for fire protection systems, where reliability under pressure is non-negotiable for life safety, adhering to strict codes and standards. HVAC systems, particularly those in large commercial and industrial buildings, also extensively utilize these fittings for their chilled water, hot water, and steam lines, benefiting from their ease of installation and leak-proof performance, which contributes to overall energy efficiency by preventing pressure losses and reducing pump loads. Furthermore, the construction industry widely employs them for general plumbing, gas lines, and structural applications where a strong, secure, and easily assembled connection is required. For example, a welding malleable iron pipe fittings solution offers distinct advantages in specific contexts where extreme rigidity and permanent bonds are preferred over threaded connections, enhancing structural integrity in critical segments and providing a permanent, tamper-resistant seal. The specific advantages, such as superior tensile strength compared to grey cast iron, excellent elongation properties that absorb system stresses, and resistance to thermal shock, translate directly into tangible benefits for the end-user: reduced maintenance costs due to fewer leaks and failures, enhanced operational safety, minimized environmental impact through fewer spills, and an extended service life for the entire piping infrastructure. The inherent design flexibility, encompassing various configurations like a black iron reducing tee for precise flow adjustments or a black iron union for convenient system segment isolation and maintenance, further solidifies their position as a preferred choice for engineers and project managers seeking resilient, cost-effective, and highly adaptable piping solutions.

Unlocking Technical Advantages and Superior Performance for Industrial Systems

The selection of piping components in demanding industrial environments is not merely a matter of compatibility but of leveraging materials that offer distinct technical advantages to ensure peak operational performance and longevity. Ward malleable iron fittings consistently outperform many alternatives due to a unique combination of metallurgical characteristics and manufacturing precision. Their defining attribute is exceptional ductility, a direct result of the annealing process which transforms brittle white iron into a material capable of significant plastic deformation without fracturing. This ductility is critical for absorbing system stresses, accommodating minor misalignments, and withstanding sudden pressure surges or vibrations inherent in industrial pipelines, thereby significantly reducing the risk of catastrophic failure and extending the lifespan of the entire system. While grey cast iron is inherently brittle and prone to sudden fracture under impact, malleable iron possesses a superior tensile strength (typically 45,000 psi minimum) and yield strength (30,000 psi minimum), providing a robust backbone for high-pressure applications and ensuring structural integrity under operational loads. Moreover, malleable iron exhibits excellent resistance to thermal shock, a crucial factor in systems experiencing rapid temperature fluctuations, such as steam lines or process heating/cooling circuits, preventing the cracking often seen in less resilient materials. The threaded connections, especially those on a black iron union fitting, are engineered for precise, leak-proof performance under rated pressures, thanks to precision machining and strict adherence to threading standards like NPT or BSPT. This meticulous engineering minimizes fluid loss, reduces maintenance overhead, and contributes to the overall energy efficiency of the system by maintaining optimal pressure and flow. For specific scenarios requiring permanent and high-integrity bonds, the option of welding malleable iron pipe fittings offers an alternative that capitalizes on the material's improved weldability compared to grey cast iron, providing an even more rigid and secure connection for critical, non-dismountable sections of a pipeline. Furthermore, the option of hot-dip galvanization (a process adhering to ASTM A153/A123) significantly enhances the corrosion resistance of these fittings, making them suitable for outdoor installations or applications involving corrosive fluids, thereby extending their service life considerably in challenging environments. From a cost-effectiveness perspective, while the initial investment might be slightly higher than some very basic alternatives, the extended service life, reduced need for repairs, and enhanced safety profile of high-quality ward malleable iron fittings translate into a significantly lower total cost of ownership (TCO) over the operational lifespan of the industrial system. This blend of mechanical robustness, resistance to environmental stressors, and long-term economic viability positions malleable iron as a superior choice for discerning engineers and project managers aiming for enduring performance.

Choosing Excellence: Manufacturer Comparison and Selection Criteria

In the procurement of critical components such as ward malleable iron fittings, the selection of a manufacturer is as crucial as the product specifications themselves. Discerning buyers in the B2B sphere understand that not all manufacturers offer the same caliber of quality, consistency, and support. A truly reliable manufacturer differentiates itself through several key criteria that extend beyond mere price points. Firstly, an unwavering commitment to quality assurance, evidenced by rigorous adherence to international standards like ISO 9001 for quality management systems, ANSI B16.3 for dimensional and material specifications, EN 10242 for thread and material properties, and ASTM A197 for malleable iron castings, is non-negotiable. This extends beyond mere certification to demonstrable processes, including rigorous material testing (e.g., spectrographic analysis of raw melts), precise dimensional accuracy checks using advanced metrology (e.g., optical comparators, CMMs), and comprehensive hydrostatic and non-destructive testing for every batch. Secondly, technological capability, encompassing modern automated casting facilities, advanced CNC machining centers for precision threading (crucial for a leak-proof black iron union), and state-of-the-art galvanization lines, ensures consistent product quality and performance output. A reputable manufacturer will invest heavily in research and development to continuously improve product design, material properties, and manufacturing efficiencies, responding to evolving industry demands, for example, by optimizing the design of a black iron reducing tee for improved flow dynamics and reduced turbulence. Thirdly, extensive experience and a proven track record in the industry provide invaluable assurance. Manufacturers with decades of specialized experience in producing ward malleable iron fittings possess deep institutional knowledge, enabling them to foresee and address potential challenges, and deliver solutions tailored to specific industrial requirements, from standard sizes to bespoke configurations. Fourthly, global distribution capabilities and efficient logistics networks are vital for timely project completion, particularly for international clients. This includes robust packaging to prevent damage during transit and streamlined customs procedures. Finally, superior customer service, including comprehensive technical support from experienced engineers, responsive communication channels, and flexible solutions for bespoke requirements, underpins a strong and lasting partnership. This includes transparent delivery schedules, clear warranty policies, and readily available after-sales support for any operational or installation queries. By meticulously evaluating these factors, B2B decision-makers can identify a manufacturing partner that not only supplies high-quality ward malleable iron fittings but also acts as a strategic ally in achieving operational excellence and project success, significantly enhancing the trustworthiness and long-term viability of their industrial investments.

Tailored Excellence: Customised Solutions and Collaborative Project Development

In today's complex industrial landscape, off-the-shelf solutions, while broadly applicable, may not always meet the unique and highly specific demands of every project. This is where the capability for customized solutions becomes a significant differentiator for manufacturers of ward malleable iron fittings. Leading suppliers recognize that industrial processes often involve unique configurations, specialized fluid characteristics, or extreme environmental conditions that necessitate fittings engineered precisely to those parameters. Customization can involve modifications to standard designs, such as specific dimensions for unusual pipe diameters, unique thread types beyond standard NPT or BSPT, or fittings with non-standard angles and bends to accommodate spatial constraints in intricate piping layouts. For instance, a bespoke black iron reducing tee might be required for a very specific flow reduction in a limited space, or a specially designed black iron union fitting for ease of maintenance in a confined area where standard tools cannot operate. It can also extend to specialized surface treatments beyond standard galvanization, such as specialized epoxy coatings for enhanced chemical resistance against aggressive media, or specific paint finishes for aesthetic or identification purposes in highly regulated environments (e.g., color-coding for different fluid types). Manufacturers offering such services typically boast a robust in-house engineering and design department capable of translating complex client requirements into detailed technical drawings and functional prototypes, often utilizing advanced CAD/CAM software and finite element analysis (FEA) for stress testing. This collaborative approach involves close consultation with the client's engineering team from concept to final product, leveraging simulation tools to optimize the design for performance, manufacturability, and cost-effectiveness. This not only ensures that the customized ward malleable iron fittings seamlessly integrate into the existing or planned infrastructure but also guarantees that they perform optimally under the specific operational loads and environmental conditions, often exceeding standard expectations. Furthermore, rapid prototyping capabilities and flexible production runs allow for efficient delivery of these specialized components, minimizing lead times and preventing costly project delays. This commitment to delivering tailored excellence underscores a manufacturer’s dedication to partnership and innovation, demonstrating a deep understanding of customer needs and a willingness to go beyond standard offerings to ensure project success. For B2B clients facing unique challenges, this capability for customized solutions represents a significant value proposition, providing access to highly specific, high-performance fittings that directly contribute to the overall efficiency, safety, and longevity of their industrial systems, building lasting trust and collaboration.

Real-World Impact: Application Case Studies and Client Successes

The theoretical advantages of ward malleable iron fittings are best illustrated through their tangible impact in real-world industrial applications, demonstrating their reliability and the profound return on investment they provide. Consider a large-scale chemical processing plant in Texas that required a robust and vibration-resistant piping network for conveying highly corrosive solutions at elevated temperatures (up to 180°C). The plant previously experienced frequent leaks and material fatigue with stainless steel alternatives due to thermal cycling, leading to costly downtime and significant safety concerns. By transitioning to high-quality galvanized ward malleable iron fittings, specifically engineered for enhanced corrosion resistance (with a thicker zinc coating conforming to ASTM A153) and designed to accommodate thermal expansion, the plant witnessed a dramatic reduction in unscheduled maintenance events. Over a period of five years, operational uptime increased by 15%, and maintenance costs related to pipe fittings decreased by 25%, directly attributable to the superior durability and leak-proof integrity of the new fittings, including numerous black iron union connections that facilitated easier system segment isolation for routine inspections. In another compelling example, a municipal water treatment facility in California undergoing a major infrastructure upgrade faced the challenge of installing a new distribution network that needed to withstand significant ground shifts and hydrostatic pressures without compromising integrity, particularly in an earthquake-prone zone. The project opted for large-diameter (6-inch) ward malleable iron fittings due to their inherent ductility and resistance to shock and seismic forces. Post-installation, comprehensive pressure testing and ongoing monitoring revealed virtually zero instances of joint leakage, even during periods of minor seismic activity, a testament to the fittings’ ability to absorb external stresses without brittle fracture. The project also strategically leveraged specific welding malleable iron pipe fittings in areas requiring maximum rigidity and tamper-proof connections, contributing to the overall structural stability and long-term reliability of the new water main. Furthermore, a customer testimonial from a major HVAC contractor operating across the Midwest highlighted how the ease of installation and consistent thread quality of a manufacturer's black iron union fitting significantly reduced installation time on a complex commercial building project by 10%, leading to substantial labor cost savings and earlier project completion. These diverse case studies underscore the practical, quantifiable benefits of choosing premium malleable iron fittings: enhanced safety, extended operational lifespan, reduced maintenance expenses, and improved overall system efficiency, providing compelling evidence of their value proposition in demanding industrial environments.

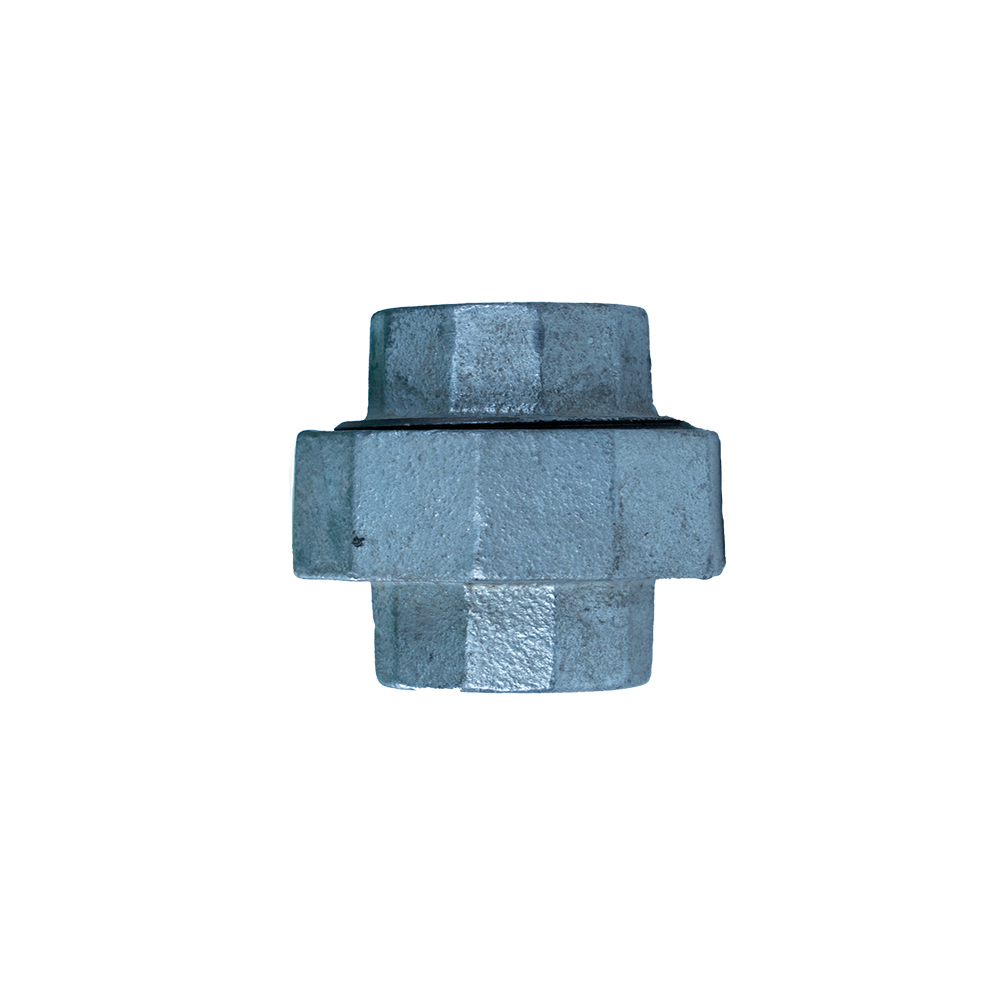

Figure 2: An industrial setting showcasing the robust integration of ward malleable iron fittings within a complex piping system, vital for ensuring operational continuity and safety.

Addressing Common Concerns: Frequently Asked Questions (FAQ)

Selecting the right piping components often involves a host of questions, particularly for technical professionals and project managers seeking to optimize their systems. Here, we address some of the most frequently asked questions regarding ward malleable iron fittings to provide clarity and instill confidence. One common inquiry is: "What is the key difference between grey cast iron and ward malleable iron fittings?" The fundamental distinction lies in their microstructure and resulting mechanical properties. Grey cast iron is brittle due to its graphite flakes, making it prone to cracking under shock or stress and unsuitable for applications requiring ductility. Malleable iron, conversely, undergoes an annealing process that transforms its carbon into ductile graphite nodules (temper carbon), imparting significantly higher tensile strength, yield strength, and elongation. This makes it far more resistant to impact, vibration, and deformation, essential for a reliable black iron union in dynamic industrial settings. Another frequent question is about their suitability for different fluids: "Can these fittings be used for highly corrosive chemicals or very high-temperature steam?" While standard black malleable iron fittings are generally suitable for water, air, and non-corrosive gases within specified temperature ranges (e.g., up to 232°C for continuous service), galvanized ward malleable iron fittings offer enhanced corrosion resistance for mildly corrosive fluids or outdoor exposure where atmospheric corrosion is a concern. For highly aggressive corrosive chemicals or extreme temperatures beyond their rated limits, specialized materials (e.g., stainless steel, alloys) or specific internal coatings would be necessary, and detailed consultation with the manufacturer and chemical compatibility charts are always recommended. Regarding installation, a common query is: "Are there specific installation considerations for ward malleable iron fittings?" While relatively easy to install due to their standardized threaded connections, proper pipe preparation (clean threads, no burrs), correct thread sealant application (Teflon tape or pipe dope compatible with the fluid), and adequate tightening torque are crucial to ensure leak-proof seals, especially for a black iron union fitting. Over-tightening can cause stress fractures, while under-tightening can lead to leaks; manufacturers often provide recommended torque values. Furthermore, understanding the pressure ratings (e.g., Class 150 or Class 300) and temperature limits is vital to match the fitting precisely to the system's operational parameters, ensuring safety and performance longevity. Finally, "What is the typical lifespan of ward malleable iron fittings?" With proper installation, in appropriate operating conditions, and with minimal exposure to extreme corrosives, these fittings can last for several decades, often outliving the pipes themselves, particularly when hot-dip galvanized for superior corrosion protection. Their inherent durability and resistance to fatigue ensure a long, reliable service life, showcasing their long-term value and reliability.

Ensuring Trust: Logistics, Warranty, and Dedicated Customer Support

For B2B clients, the efficacy of a product is inextricably linked to the reliability of its supply chain, the assurances of its quality, and the responsiveness of its support system. A leading manufacturer of ward malleable iron fittings understands that trust is built through consistent performance not just of the product, but of the entire service ecosystem. Regarding logistics, efficient and reliable delivery is paramount for maintaining project timelines and operational continuity. Reputable manufacturers often operate sophisticated global supply chain networks, ensuring that orders, whether large bulk quantities for an infrastructure project or specialized components like a particular black iron union, are delivered on time and intact, anywhere in the world. This includes careful packaging to protect fittings during transit from environmental damage (e.g., rust, moisture) or physical impact, often utilizing robust crating, protective wraps, and secure palletizing. Transparent communication about delivery schedules, real-time tracking information, and efficient customs documentation is standard practice, mitigating potential project delays and providing peace of mind to project managers navigating complex international shipments. Coupled with dependable logistics are comprehensive warranty policies. A trustworthy manufacturer stands behind the quality of its ward malleable iron fittings with a clear, industry-standard warranty that covers defects in material and workmanship, typically ranging from one to five years depending on the specific product, application, and adherence to installation guidelines. This warranty commitment signifies confidence in their advanced manufacturing processes and premium materials, offering a critical layer of protection for the client's investment and reducing financial risk. Beyond initial delivery and warranty, dedicated customer support is a hallmark of a trustworthy partner. This encompasses readily available technical assistance for installation guidance, troubleshooting common issues, and providing application-specific inquiries. Whether it's expert advice on selecting the right size of a black iron reducing tee for a specific flow rate or understanding the pressure ratings for a complex steam system, expert support from qualified engineers ensures optimal product utilization and resolves challenges promptly. Furthermore, responsive after-sales service, including efficient handling of any claims or replacement part requests, solidifies the long-term relationship. This holistic approach, from pre-sales consultation and seamless logistics to robust warranties and ongoing technical support, ensures that clients receive not just high-quality ward malleable iron fittings, but a complete, trustworthy solution that contributes significantly to their operational success and minimizes risk throughout the entire lifecycle of their industrial projects.

Conclusion: The Enduring Value of Ward Malleable Iron Fittings in Modern Industry

In summation, the journey through the metallurgy, manufacturing, application, and advantages of ward malleable iron fittings reveals why they remain an indispensable and highly valued component in the demanding realm of industrial piping systems. Their unique combination of inherent strength, exceptional ductility, and remarkable resistance to shock and vibration, achieved through a sophisticated and meticulously controlled annealing process, positions them far above more brittle alternatives like grey cast iron. From the intricate demands of petrochemical facilities and high-pressure steam lines to essential municipal water infrastructure, advanced fire protection systems, and complex HVAC networks, these fittings consistently deliver reliable, leak-proof, and long-lasting connections that withstand the rigors of continuous industrial operation. The rigorous manufacturing protocols, including precision casting, advanced CNC machining for exact threading, and comprehensive multi-stage quality assurance processes adhering to global standards such as ISO, ANSI, and ASTM, ensure that every single ward malleable iron fitting meets the highest benchmarks for performance, safety, and longevity. Products like the Union with Brass Seat Threading Fitting, embodying precision engineering and material excellence, exemplify this unwavering commitment to superior quality. The strategic benefits for B2B decision-makers and technical professionals are clear and quantifiable: reduced operational downtime, significantly lower maintenance costs over the entire lifecycle of the system, enhanced overall system safety through reliable connections, and the invaluable peace of mind that comes from investing in components known for their unwavering durability and consistent performance. As industries continue to evolve, demanding greater efficiency, enhanced sustainability, and superior resilience from their critical infrastructure, the foundational strength, remarkable adaptability, and proven reliability of high-quality ward malleable iron fittings will only grow in importance. Choosing a manufacturing partner committed to continuous innovation, stringent quality control, providing tailored solutions, and offering unparalleled customer support is not just a procurement decision; it is a strategic partnership that safeguards your investments, minimizes operational risks, and ensures the uninterrupted flow of your critical industrial processes for decades to come. Embrace the proven reliability and long-term value that only expertly crafted malleable iron fittings can provide for your most challenging and vital industrial applications.

Figure 3: Emphasizing the meticulous quality inspection process that ensures the integrity and performance of every ward malleable iron fitting leaving the factory.

Authoritative References and Industry Insights

The information presented in this article is supported by established industry standards, research, and market analyses from reputable sources. For further in-depth knowledge and validation regarding ward malleable iron fittings and related topics, the following resources are recommended:

- » Grand View Research. (2023). Industrial Pipe Fittings Market Size, Share & Trends Analysis Report. This report provides comprehensive market insights and growth projections for the industrial pipe fittings sector. Available at: https://www.grandviewresearch.com/industry-analysis/industrial-pipe-fittings-market

- » ASTM International. ASTM A197/A197M-21: Standard Specification for Cupola Malleable Iron. Essential for understanding the material properties and manufacturing requirements of malleable iron castings. Available at: https://www.astm.org/a0197_a0197m.htm

- » ASME. ASME B16.3-2023: Malleable Iron Threaded Fittings. This standard defines the dimensions, material, pressure-temperature ratings, and testing requirements for malleable iron threaded fittings. Available at: https://www.asme.org/codes-standards/products/boiler-pressure-vessel-code/malleable-iron-threaded-fittings-b16-3-2023

- » ISO. ISO 7-1: Pipe threads where pressure-tight joints are made on the threads — Part 1: Dimensions, tolerances and designation. Crucial for understanding global threading standards for pipe fittings. Available via: https://www.iso.org/standard/44747.html

- » European Committee for Standardization. EN 10242: Pipe fittings of malleable cast iron. This European standard specifies the requirements for malleable cast iron pipe fittings with threaded ends. (Direct link to content may vary by region due to paywalls, but general standard info accessible via national standardization bodies).

Post time: Авг-10-2025