Official Website

Phone: 0316-2652671

Email: fanda@pannext-casting.com

Mobile: 0086-15690252169

Address: 236 West Guangming Road, Langfang, Hebei, China

The global pipeline connection industry has seen a technological leap in recent years, led by the rising use of **NPT couplings** across petrochemical, construction, and general engineering markets. Among these, the 3 8 NPT fitting stands out for its versatility and reliability. The fitting is indispensable in both industrial and residential projects targeting leak-free and robust thread-based pipe connections.

According to the American Society of Mechanical Engineers (ASME) Pipe Standards Forum, NPT (National Pipe Taper) threads are the industry’s preferred connection method for pressure pipelines, offering superior sealing performance (reference: ASME B1.20.1 standard).

The growing demand for MRO (Maintenance, Repair, Operations) services, coupled with increasing urban infrastructure, is propelling the use of **npt couplings**, **npt pipe coupling**, as well as variants like **1 4 npt coupling** and **1 2 npt coupling**. Export insights from Pipestudy Technical Forum indicate that market share for NPT sockets, particularly in Mideast and Southeast Asia, is projected to grow at over 6.2% CAGR through 2027.

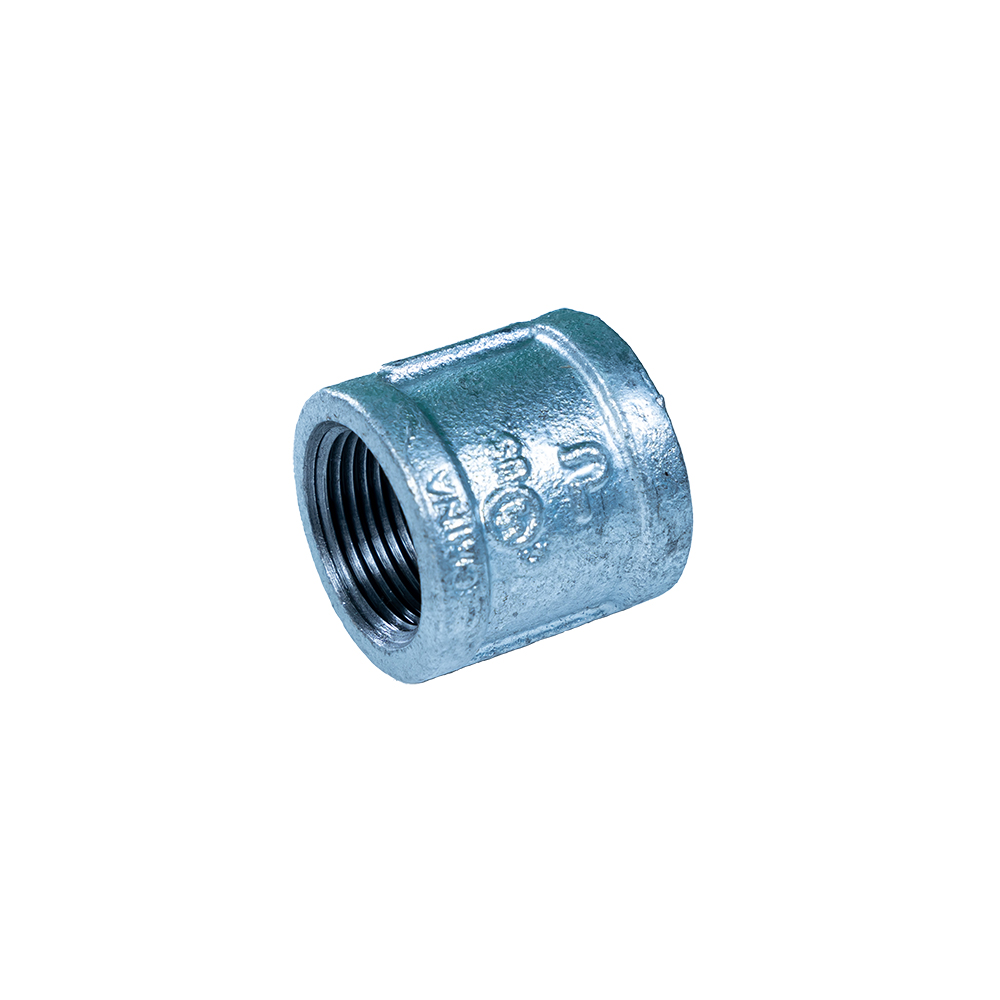

Product Link: Black or Galvanized Socket NPT COUPLINGS

| Parameter | Specification | Description |

|---|---|---|

| Nominal Size | 3/8 inch | Standard NPT size for medium flow |

| Thread Type | NPT (National Pipe Taper) | Conforms to ASME/ANSI B1.20.1 |

| Material | Black/Hot-Dip Galvanized Iron | Available in corrosion resistant options |

| Max Pressure | 150 - 300 PSI | Depends on wall thickness & material |

| Temperature Range | -20°C to 300°C | Broad temperature resistance |

| End Connections | Female x Female | Enables pipeline extension or joining |

| Compliance | ISO 49, DIN EN 10241 | International quality standards |

For installations demanding resilience against corrosion, galvanized coating is preferable over bare black iron, notably in humid or outdoor conditions (source: Chemical Process Engineering Journal).

- Oil & Gas Transmission Pipes

- Water & Wastewater Engineering

- Building Firefighting Piping

- HVAC (Heating, Ventilation, & Air Conditioning)

- Industrial Automation Hydraulic Systems

- Compressed Air & Gas Distribution

- Agricultural Irrigation Networks

- Shipbuilding & Marine Engineering

The 3 8 NPT fitting achieves widespread adoption wherever a robust, leak-tight threaded connection is required. Its compact size is especially suited to so-called “branches” or “drops” in complex plumbing.

- 1. What materials are used for 3 8 NPT fitting?

-

Answer: Primarily black malleable iron or hot-dip galvanized steel, conforming to ISO 49 and DIN EN 10241.

For high-corrosion applications, galvanized or alloy coated variants are preferable (reference). - 2. What are the standard installation requirements?

- Answer: Install according to ASME B31.1, use compatible thread sealant/PTFE tape, and tighten with a proper torque to avoid over-thread deformation.

- 3. What is the difference between NPT and BSPT?

- Answer: Both are taper-threaded, but NPT (US standard) and BSPT (British standard) have different pitch angles and thread shapes, thus are not compatible (source).

- 4. What pressure and temperature can a 3/8 NPT fitting withstand?

- Answer: Typical max pressure: 150–300 PSI; temperature: –20°C to 300°C, depending on material and wall thickness. Industrial coatings enhance limits further.

- 5. How is a 3 8 NPT fitting sized versus a 1 4 npt coupling or 1 2 npt coupling?

- Answer: The size refers to nominal bore—the 3 8 NPT fitting (3/8") has an OD of 0.675" (~17.15 mm), sandwiched between 1/4" (0.540" OD) and 1/2" (0.840" OD).

- 6. What is the surface treatment used for Black or Galvanized Socket NPT COUPLINGS?

- Answer: Black couplings are anti-rust oiled; galvanized types are hot-dip galvanized (zinc layer ≥ 40 microns per EN 10241).

- 7. Are NPT couplings reusable?

- Answer: Yes; however, thread quality and seal integrity decrease with each use, so best practice is to use new fittings for critical/pipeline applications each time (Plant Engineering Journal).

- More than 15 years of expertise in producing half a billion quality pipe fittings for global markets.

- Strict adherence to ASME, ISO 49, DIN EN 10241 and in-house robust pressure/leak testing.

- Full material traceability and custom/OEM service.

- Comprehensive inventory: 3 8 NPT fitting, npt couplings, npt pipe coupling, 1 4 npt coupling, 1 2 npt coupling and more.

- Competitive export pricing, super-fast delivery and professional after-sales.

- Professional technical support—contact us anytime by email or call 0086-15690252169.

Selecting the right 3 8 NPT fitting is critical to piping system safety, durability, and performance. As npt couplings continue to dominate industry preferences, working with a trustworthy supplier like Langfang Pannext Pipe Fitting Co., Ltd. ensures you enjoy best-in-class standards, technical support, and value.

[1] “Tech Differences: NPT vs. BSPT Threads” – MISUMI USA Industrial Blog

[2] “Pipe Thread Sealing Guide” – Plant Engineering Journal

[3] “NPT Thread Standards” – ASME Technical

[4] “Material Selection for Pipe Fittings” – Chemical Process Engineering Journal

[5] “Pipe Fitting Types and Uses” – Haberturk Engineering Guide

[6] “Pipe Fittings Training Guide” – Pipestudy Forum

[7] “Pipe Fitting: Engineering Toolbox” – Engineering Toolbox

Post time: Julai-26-2025

This is the first article