In the intricate infrastructure of plumbing and industrial systems, the seamless operation of transporting fluids relies on the harmonious combination of various components. From creating connections to altering flow directions, each part plays a pivotal role. Let's explore the significance of pipe and pipe fitting, coupling for pipe fitting, galvanized union, fitting elbow 90, Và elbow plumbing fittings in constructing robust piping networks.

Crafting Reliable Connections with Pipe and Pipe Fitting Combinations

The success of any piping system hinges on the compatibility and functionality of pipe and pipe fitting pairings. Pipes serve as the conduits for fluids, while fittings act as the connectors that enable changes in direction, branching, and size adjustments. For instance, in a commercial plumbing setup, pipes of varying diameters need precise fittings to ensure water flows smoothly to fixtures. These fittings, whether they're tees, crosses, or adapters, must be carefully selected to match the pipe material and pressure requirements. The right combination not only guarantees leak - free operation but also enhances the overall durability and efficiency of the system, preventing costly disruptions due to faulty connections.

Strengthening Piping Networks with Coupling for Pipe Fitting

To maintain the integrity of a piping system, coupling for pipe fitting serves as a crucial link between separate pipe sections. Couplings are designed to join two pipes end - to - end, providing a secure and often flexible connection. In industrial applications where pipes may experience vibrations or thermal expansion, couplings can absorb these movements, preventing damage to the pipes and connections. They come in various materials, such as stainless steel, brass, or rubber, each suited to different environmental conditions. Whether it's for a water supply line in a residential building or a chemical - carrying pipeline in a factory, the proper coupling ensures that the pipes remain firmly connected, allowing for uninterrupted fluid flow.

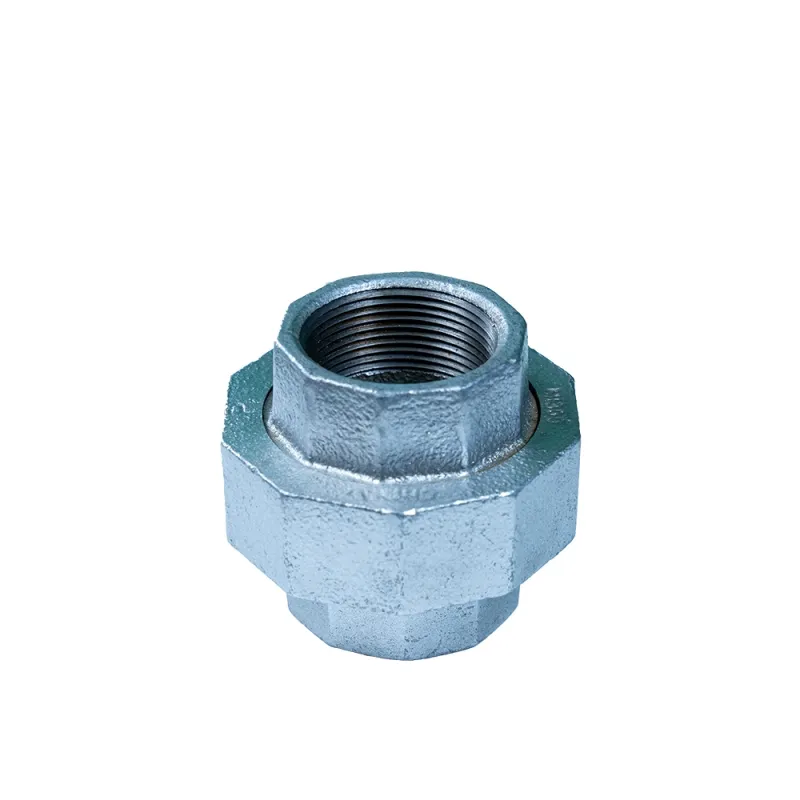

Ensuring Long - Lasting Durability with Galvanized Union

When it comes to withstanding the test of time and harsh environments, galvanized union fittings are a top choice. Galvanization involves coating a metal union with a layer of zinc, which provides exceptional corrosion resistance. This makes galvanized unions ideal for outdoor plumbing systems, as well as in industrial settings where exposure to moisture, chemicals, or corrosive substances is common. A galvanized union consists of three parts: two end pieces with male threads and a center nut with female threads, allowing for easy disassembly and reassembly during maintenance. The zinc coating not only protects the union from rust and degradation but also extends the lifespan of the entire piping system, reducing the need for frequent replacements.

Navigating Direction Changes with Fitting Elbow 90

In the layout of any piping system, there are often instances where a sharp change in direction is required. This is where fitting elbow 90 comes into play. A 90 - degree elbow fitting creates a right - angled turn in the pipe, enabling it to navigate around obstacles, such as walls or structural beams. In heating, ventilation, and air - conditioning (HVAC) systems, 90 - degree elbows are used to direct air ducts precisely to different areas of a building. In plumbing, they ensure that water pipes reach fixtures located at right angles to the main supply line. These elbows are available in different materials, including copper, PVC, and cast iron, and are designed to maintain smooth fluid flow even through the sharp bend, minimizing turbulence and pressure loss.

Enhancing Plumbing Efficiency with Elbow Plumbing Fittings

For plumbing systems, elbow plumbing fittings are essential for optimizing the flow of water and waste. These elbows come in various angles, but the 45 - degree and 90 - degree varieties are the most commonly used. A 45 - degree elbow fitting offers a more gradual turn, reducing the likelihood of debris buildup and minimizing pressure loss. In drainage systems, this type of elbow helps wastewater flow smoothly towards the main sewer line, preventing clogs. Meanwhile, 90 - degree elbow plumbing fittings are crucial for creating precise right - angled connections in tight spaces, such as under sinks or in walls. Made from durable materials like ABS plastic or galvanized steel, these fittings are built to withstand the rigors of daily use and ensure the long - term functionality of the plumbing system.

Pipe Fitting FAQs

How can I prevent leaks in pipe and pipe fitting connections?

To prevent leaks, ensure that the pipes and fittings are clean and free of debris before assembly. Use appropriate sealants or thread - wrapping materials like Teflon tape on threaded connections. Make sure the fittings are tightened properly but avoid over - tightening, which can damage the threads. Additionally, choose fittings that are compatible with the pipe material and pressure rating of your system.

What factors should I consider when selecting a coupling for pipe fitting?

Consider the material of the coupling based on the fluid or gas being transported and the environmental conditions. For example, use corrosion - resistant materials for outdoor or chemical - handling applications. Also, check the size compatibility with your pipes, and consider the type of connection (threaded, push - fit, etc.) that best suits your installation needs. The coupling's ability to accommodate movement, such as vibration or thermal expansion, is also important for long - term reliability.

How do I maintain galvanized union fittings?

Regularly inspect galvanized union fittings for signs of rust or damage, especially in areas exposed to moisture. If minor rust spots are present, you can clean them with a wire brush and apply a protective coating. Avoid using abrasive cleaners that could damage the zinc coating. During maintenance, ensure that the union is tightened securely but not excessively, as over - tightening can cause the threads to strip or the fitting to crack.

Can fitting elbow 90 be used in high - pressure systems?

Yes, many fitting elbow 90 options are designed to withstand high - pressure applications. However, it's crucial to select elbows that are rated for the specific pressure of your system. Look for elbows made from sturdy materials like stainless steel or heavy - duty cast iron, which can handle higher pressures without deforming or leaking. Always check the manufacturer's specifications to ensure compatibility with your system's requirements.

What are the benefits of using elbow plumbing fittings in drainage systems?

Elbow plumbing fittings, especially 45 - degree elbows, help maintain a smooth flow of wastewater in drainage systems. Their angled design reduces the chances of solid waste getting stuck, minimizing the risk of clogs. Additionally, they allow for flexible routing of pipes in tight spaces, making it easier to install and maintain the plumbing system. By ensuring efficient drainage, these fittings contribute to the overall hygiene and functionality of the plumbing setup.

Post time: Th7-01-2025