The Enduring Strength of Malleable Cast Iron in Modern Industries

In the rapidly evolving industrial landscape, the demand for materials that offer superior ductility, machinability, and resistance to shock while maintaining high tensile strength is paramount. Among the diverse range of ferrous alloys, malleable cast iron stands out as a critical engineering material. Its unique microstructure, achieved through a precise heat treatment process, transforms brittle white cast iron into a resilient and versatile metal. This material is indispensable across various sectors, from automotive and agriculture to piping and construction, providing robust solutions where traditional cast iron might fail due to its inherent brittleness. Understanding its metallurgical properties, manufacturing nuances, and diverse applications is key for professionals seeking reliable and cost-effective material solutions.

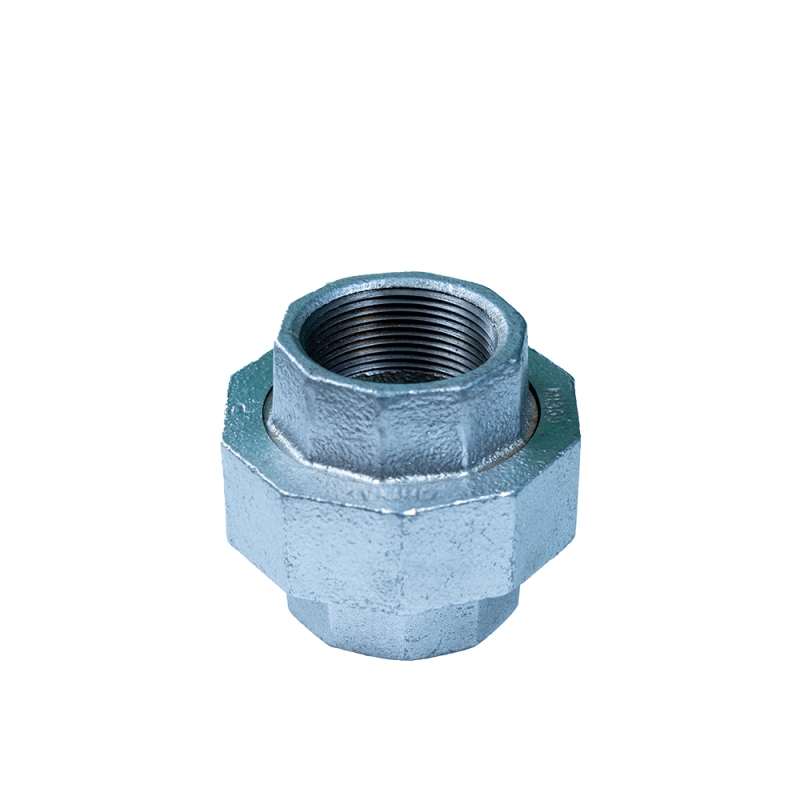

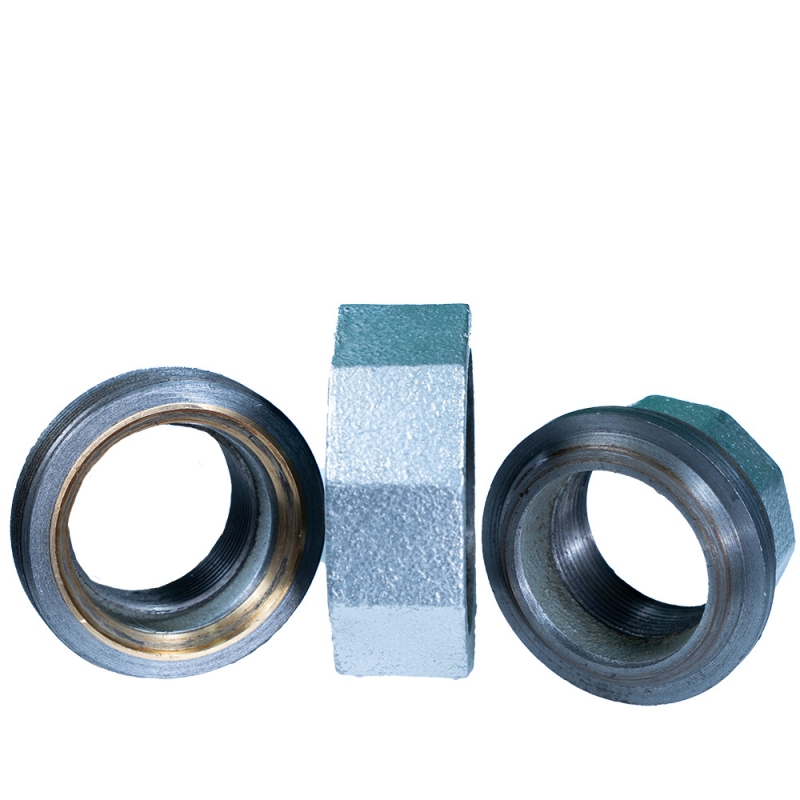

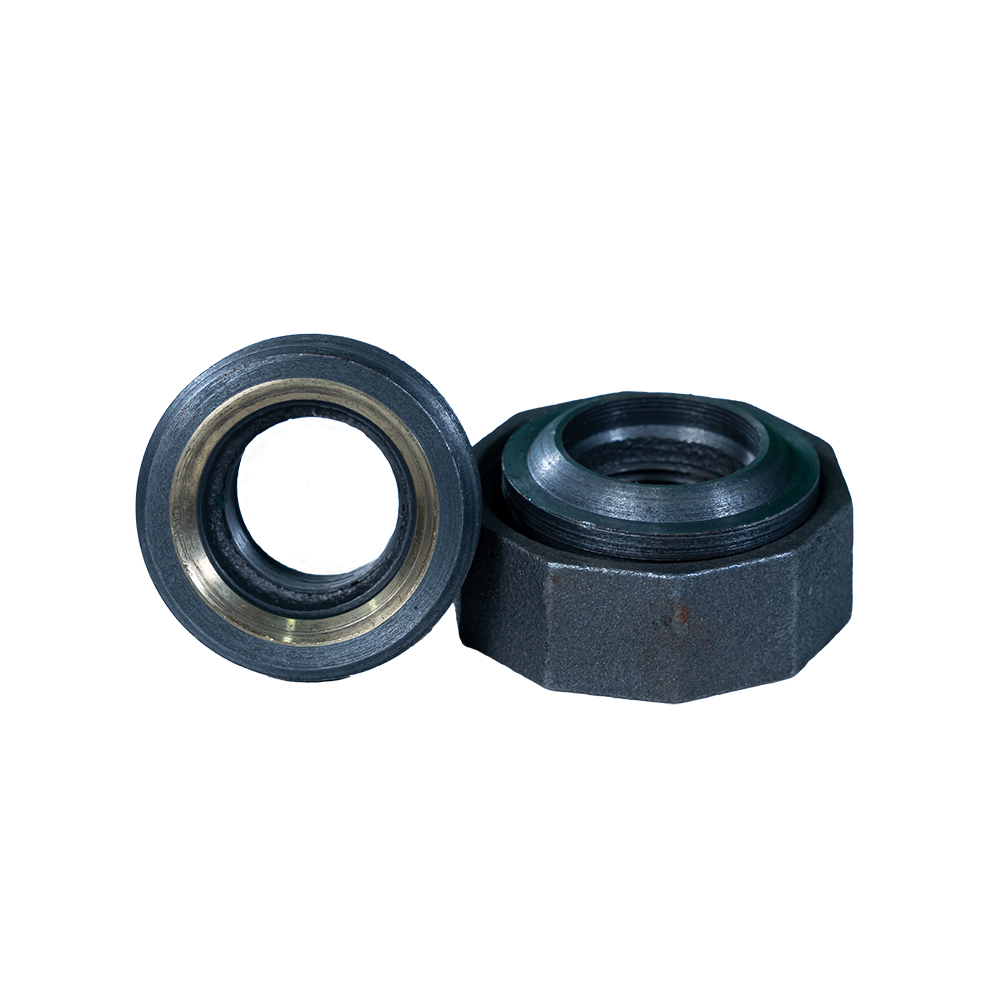

The current industry trends increasingly favor materials that contribute to enhanced operational efficiency, reduced maintenance, and prolonged service life. This focus is driving significant innovation in the field of metal casting, where the optimization of material properties for specific application scenarios is a top priority. Companies specializing in components like the High Quality Union with brass seat, which requires a material that can withstand significant stress and provide reliable sealing, often turn to advanced forms of malleable iron. The inherent flexibility and strength of this material ensure that critical infrastructure components perform consistently under demanding conditions, thereby minimizing downtime and maximizing productivity across complex industrial systems.

Delving into Malleable Cast Iron: Types and Distinct Properties

Malleable cast iron is not a singular material but rather a family of irons whose properties are tailored through specific heat treatments. The primary types are distinguished by their matrix microstructures and the form of carbon they contain after annealing. Ferritic malleable cast iron, for instance, is characterized by a ferrite matrix with temper carbon nodules. This structure provides excellent ductility and toughness, making it suitable for components that require good machinability and impact resistance. Its typical elongation can reach up to 18%, significantly higher than that of gray cast iron, making it highly valuable in applications where dynamic loads are common. The presence of temper carbon also enhances its damping capacity, an essential characteristic for noise and vibration reduction in machinery.

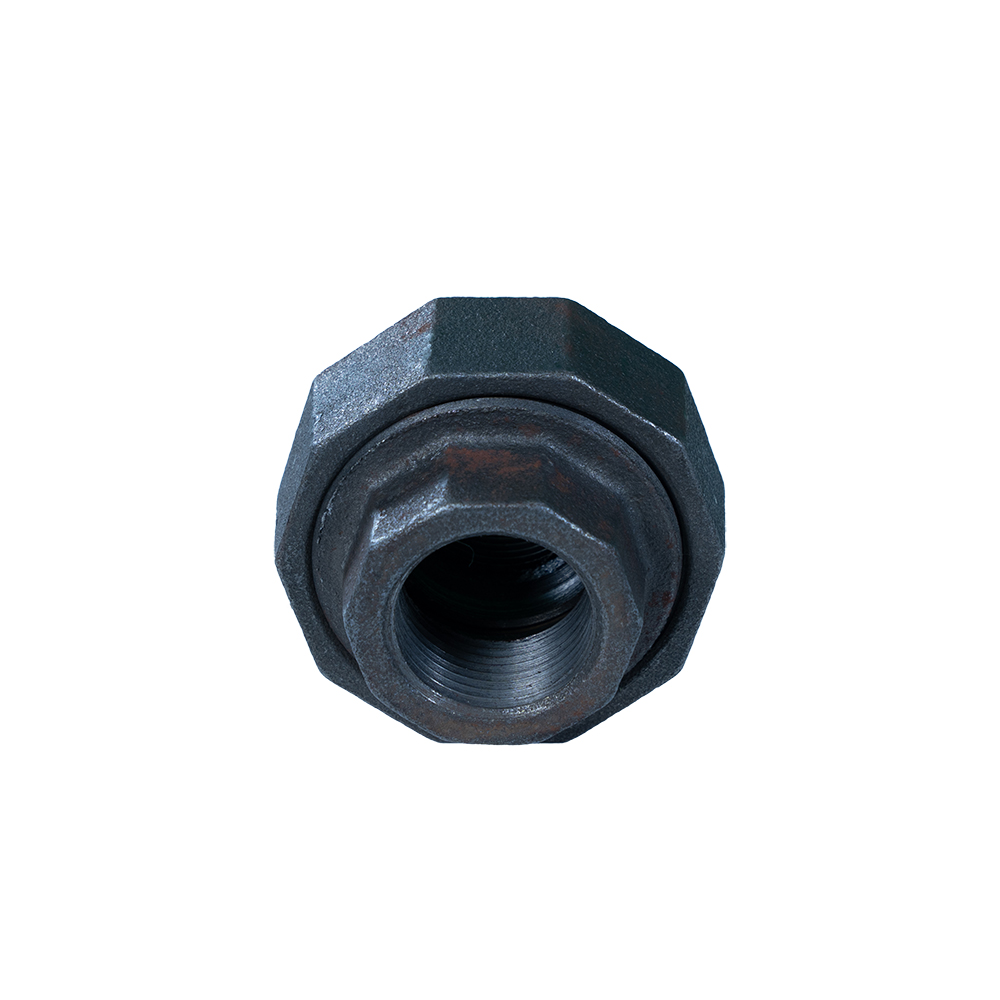

Another prominent type is black heart malleable cast iron, which obtains its name from the dark, velvety fracture surface caused by the finely dispersed temper carbon. Produced by annealing white cast iron in a neutral atmosphere, this process allows for the graphitization of carbon into nodular aggregates within a ferrite matrix, similar to ferritic types but often with slightly different mechanical properties tailored for specific uses. Black heart malleable iron exhibits good tensile strength and excellent shock absorption, making it ideal for automotive parts, agricultural machinery, and pipe fittings. The microstructure also contributes to superior thermal conductivity and corrosion resistance compared to other cast iron variants, extending the lifespan of components in harsh environments and reducing the frequency of replacements in critical systems like a cast iron union used in pipelines.

The Advanced Manufacturing Process of Malleable Cast Iron

The production of malleable cast iron is a sophisticated process that begins with the creation of white cast iron, an alloy with high carbon and silicon content. This initial casting step is critical, involving precise control over molten metal composition and pouring temperatures to ensure a uniform carbide structure throughout the component. After casting, the raw white cast iron undergoes a specialized heat treatment known as malleabilizing. This annealing process involves heating the castings to high temperatures (typically between 850°C and 970°C) for an extended period in a controlled atmosphere, followed by slow cooling. During this thermal cycle, the brittle cementite (iron carbide) decomposes into temper carbon (irregular nodules of graphite) and a softer ferrite matrix. This transformation is what imparts the characteristic ductility and machinability to the material, turning it from a brittle substance into one that can withstand significant deformation without fracturing.

Beyond the initial casting and annealing, the manufacturing of high-quality malleable cast iron components, such as a precision cast iron union, often incorporates advanced techniques. Modern malleable iron foundry operations utilize state-of-the-art facilities that include induction furnaces for melting, automated molding lines for consistent production, and sophisticated heat treatment furnaces for precise temperature control. Post-annealing, products may undergo CNC machining for intricate geometries, ensuring tight tolerances and a perfect fit. Rigorous inspection standards are applied throughout the process, adhering to international benchmarks like ISO 9001 for quality management and ANSI standards for product dimensions and performance. Each batch of products undergoes comprehensive testing, including tensile strength, yield strength, elongation, hardness, and hydrostatic pressure tests for fittings, guaranteeing an extended service life and reliable performance in demanding applications such as in petrochemical, metallurgy, and water supply and drainage industries.

Technical Specifications and Performance of Malleable Cast Iron

The exceptional performance of malleable cast iron stems from its meticulously controlled mechanical and physical properties. Engineers and procurement specialists rely on these precise parameters to select the optimal material for their applications. Below is a table summarizing key technical specifications for typical grades of ferritic malleable cast iron, highlighting its competitive edge over other materials.

Typical Mechanical Properties of Malleable Cast Iron (ASTM A47/A47M & EN 1562)

These robust properties mean that components made from malleable cast iron, such as the High Quality Union with brass seat, can reliably perform in challenging operational conditions, offering an optimal balance of strength and ductility. Its superior machinability also translates into reduced manufacturing costs and faster production cycles for complex parts, providing a significant competitive advantage for manufacturers and end-users alike.

Key Applications and Industry Advantages of Malleable Iron

The unique combination of strength, ductility, and machinability makes malleable cast iron an ideal material for a diverse range of demanding industrial applications. In the petrochemical industry, components must withstand high pressures, corrosive fluids, and extreme temperatures. Fittings like pipe unions, elbows, and tees made from malleable cast iron offer superior resistance to fatigue and cracking compared to standard gray iron, ensuring the integrity and safety of crucial pipeline systems. For instance, a High Quality Union with brass seat capitalizes on this material's inherent strength for the body, while the brass seat provides excellent sealing properties, crucial for preventing leaks of volatile substances and optimizing energy efficiency by minimizing fluid loss.

Within the metallurgy sector, malleable cast iron is extensively used for furnace parts, rolling mill components, and general machinery, where its high-temperature stability and wear resistance are highly valued. Its ability to absorb shock and vibration also makes it a preferred choice for heavy machinery parts in agriculture, construction, and railway industries, contributing to longer equipment lifespan and reduced operational noise. In the realm of water supply and drainage systems, the material's excellent corrosion resistance, especially when properly coated, ensures long-term performance and minimal maintenance, leading to significant cost savings over the product's lifespan. By utilizing robust materials, these sectors achieve enhanced system reliability, reduced energy consumption due to efficient fluid transfer, and prolonged periods between maintenance cycles, directly impacting overall operational profitability. A reputable malleable iron foundry contributes significantly to these advantages through consistent quality.

Why Choose Pannext Fittings: Manufacturer Expertise and Solutions

Selecting the right manufacturing partner is as crucial as choosing the right material. Pannext Fittings stands as a leading malleable iron foundry, renowned for its commitment to quality and precision engineering. With decades of experience in producing high-performance malleable cast iron components, including specialized fittings like the High Quality Union with brass seat, we combine traditional craftsmanship with cutting-edge technology. Our manufacturing facilities are equipped with advanced induction melting furnaces, automated molding lines, and precise CNC machining centers, ensuring every product meets stringent international standards such as ISO and ANSI. We pride ourselves on a robust quality control system, encompassing raw material inspection, in-process monitoring, and final product testing, guaranteeing superior mechanical properties and dimensional accuracy for every component shipped.

Pannext Fittings also excels in providing tailored solutions. Recognizing that every industrial application has unique requirements, we offer comprehensive OEM and ODM services. Whether it's a specific design modification for a cast iron union, a custom alloy formulation, or a specialized surface finish for enhanced corrosion resistance, our team of expert engineers collaborates closely with clients to transform concepts into high-performing realities. Our extensive service history includes successful partnerships with major players in the petrochemical, water treatment, and construction industries globally. This dedication to customized solutions, combined with our rigorous adherence to quality and timely delivery, makes Pannext Fittings a trusted partner for businesses seeking reliable and durable malleable cast iron components that truly fit their operational needs and contribute to long-term project success.

Case Studies and Real-World Impact

The practical application of malleable cast iron components has demonstrably improved efficiency and reliability across various industrial projects. One notable case involved a large-scale municipal water treatment plant facing frequent failures of brittle cast iron connectors due to ground shifts and water hammer effects. By replacing these with malleable cast iron fittings, specifically a robust cast iron union featuring enhanced ductility, the plant experienced a dramatic reduction in leak rates and maintenance costs. The inherent flexibility of the malleable iron absorbed dynamic stresses, extending the operational life of the pipeline system by over 30%, which translated to significant savings in labor and materials.

Another example comes from the automotive industry, where a leading manufacturer sought to reduce the weight of chassis components while maintaining critical strength and impact resistance. Through a collaborative effort with an experienced malleable iron foundry, they transitioned from heavier, forged steel parts to optimized designs made from black heart malleable cast iron. This strategic material change resulted in a 15% weight reduction per component, contributing to improved fuel efficiency and reduced emissions across their vehicle line. The excellent machinability of the malleable iron also streamlined the production process, cutting manufacturing time by 10% and enabling quicker market deployment of their updated models. These real-world successes underscore the economic and operational benefits derived from leveraging high-quality malleable cast iron solutions in challenging industrial environments.

Ensuring Trust: Quality Assurance, Certifications, and Support

At Pannext Fittings, building and maintaining trust with our clients is paramount. Our commitment to delivering high-quality malleable cast iron products is backed by comprehensive quality assurance protocols and internationally recognized certifications. We are ISO 9001:2015 certified, affirming our adherence to a robust quality management system that governs every stage from design and production to testing and delivery. Our products, including the High Quality Union with brass seat, consistently meet or exceed relevant ANSI, ASTM, and EN standards for material composition, mechanical properties, and dimensional accuracy. Furthermore, rigorous internal testing, including Spectrographic analysis for material composition, universal testing machine for tensile and yield strength, impact testing, and hydrostatic pressure testing, ensures that every batch performs as expected under demanding conditions. Our longstanding service record and partnerships with major international distributors further attest to our reliability and authority in the industry.

Frequently Asked Questions (FAQ)

-

Q: What is the typical lead time for custom malleable cast iron orders?

A: Our standard delivery cycle for custom orders ranges from 4 to 8 weeks, depending on complexity and order volume. We provide a detailed production schedule upon order confirmation. -

Q: Do your malleable cast iron fittings come with a warranty?

A: Yes, all our products are covered by a 12-month warranty against manufacturing defects, effective from the date of shipment. Detailed warranty terms are provided with each order. -

Q: How do you ensure product compatibility with existing systems?

A: Our technical support team works closely with clients to understand their existing infrastructure and specifications. We offer pre-order consultations and provide detailed technical drawings and certifications to ensure seamless integration and optimal performance.

Our dedicated customer support team is available to assist with technical queries, order tracking, and after-sales support, ensuring a seamless experience from inquiry to installation. This holistic approach to service underscores our commitment to being a reliable and authoritative partner in the malleable iron foundry industry.

Conclusion: The Future of Malleable Cast Iron

As industries continue to push the boundaries of performance and efficiency, the role of advanced materials like malleable cast iron becomes increasingly vital. Its proven track record of durability, ductility, and machinability makes it an indispensable choice for critical applications across petrochemical, metallurgical, and water treatment sectors. The ongoing advancements in malleable iron foundry technologies, combined with stringent quality control and a focus on customization, promise even greater potential for this versatile material. Embracing solutions crafted from high-quality malleable iron means investing in long-term reliability, reduced operational costs, and enhanced system integrity. For stakeholders prioritizing robust and sustainable material choices, malleable cast iron, exemplified by products like the High Quality Union with brass seat, remains a cornerstone of industrial excellence.

References

- American Society for Testing and Materials (ASTM) A47/A47M - Standard Specification for Ferritic Malleable Iron Castings.

- European Standard (EN) 1562 - Founding - Malleable Cast Irons.

- Smith, W.F., & Hashemi, J. (2006). Foundations of Materials Science and Engineering (4th ed.). McGraw-Hill.

- ASM Handbook, Vol. 15: Casting. (1988). ASM International.

Post time: أغسطس-14-2025