The 1 4 NPT 45 degree elbow and its related variations such as 1 2 45 degree elbow, 3 inch exhaust 45 degree elbow, 6 inch 45 degree elbow, and 2 45 degree elbow have become integral components in industrial and plumbing systems globally. As the demand for efficient flow redirection, corrosion resistance, and high-pressure capabilities surges across petrochemical, water supply, and exhaust industries, these fittings have also witnessed significant advancements in manufacturing and performance.

1. Global Trends and Demands for 1 4 NPT 45 Degree Elbow and Related Fittings

According to MRFR, the global pipe fittings market surpassed USD 60 billion in 2023, driven strongly by infrastructure upgrades in Asia-Pacific, the expansion of petrochemical complexes, and a pronounced need for corrosion-resistant, custom-dimension bends. The 1 4 NPT 45 degree elbow—recognized for its precise 1/4" National Pipe Thread and a 45° bend—dominates settings requiring compact, leak-proof connections in high-pressure fluid lines.

Tech innovations include advanced galvanization, higher tolerance forging, CNC finish machining, and compliance with rigorous standards such as ISO 49 and ANSI B16.11, significantly boosting lifespan and safety.

Key Related Elbow Variants and Typical Applications

- 1 2 45 degree elbow: Medium tube lines (HVAC, compressed air).

- 3 inch exhaust 45 degree elbow: Automotive, emission control, and energy systems.

- 6 inch 45 degree elbow: Industrial water mains and chemical transfer pipelines.

- 2 45 degree elbow: Oil & gas gathering, municipal water supply loops.

2. Specification Table: 1 4 NPT 45 Degree Elbow

| Parameter | Value/Type | Standard | Testing | Typical Usage |

|---|---|---|---|---|

| Nominal Size | 1/4" NPT | ANSI B1.20.1 | Thread Gauge, Leak Test | Small-bore fluid/gas lines |

| Bend Angle | 45° | ANSI B16.11 | Profilometry | Directional flow control |

| Material | Black Malleable Iron/Galvanized Steel | ISO 49, ASTM A197 | Spectrometry, Hardness | Corrosive & non-corrosive media |

| Wall Thickness | Sch 40 (Standard) | ASME B36.10 | Ultrasonic, Micrometer | Pressure/vacuum lines |

| Maximum Pressure | 150 psi (Threaded), 300 psi (Forged) | ASME B31.3 | Hydrotest | Hydraulic/pneumatic |

| Surface Coating | Galvanized/Black Painted | ISO 1461 | Coating Thickness Test | Anti-rust, outdoors/indoors |

| Temperature Range | -20°C to +350°C | ISO 7005-1 | Thermal Endurance Test | Heated/cold lines |

3. Manufacturing Process of 1 4 NPT 45 Degree Elbow

Industry-Leading Process: The 1 4 npt 45 degree elbow undergoes a rigorous, multi-stage process:

Raw Material Selection

Steel Bars

Melting & Casting

Sand Molds

Forging & Heat Treating

structure

CNC Machining

Surface Finish

Galvanization / Painting

or Epoxy Coat

Quality Inspection

ISO/ANSI Cert.

Key Features:

- Material: Malleable iron provides strength, while galvanization ensures a corrosion-resistant finish.

- Manufacturing Precision: CNC thread machining guarantees leak-tight fits per ANSI B1.20.1.

- Testing: 100% leak-pressure/hydrostatic tests exceed ISO 49 / ANSI standards.

Short Video Explanation:

Watch: How Threaded 45 Degree Elbows Are Made (Industry Animation)

4. 1 4 NPT 45 Degree Elbow vs Leading Alternatives - Data Comparison

| Parameter | 1 4 NPT 45° Elbow | 1 2 45° Elbow | 3" Exhaust 45° Elbow | 6" 45° Elbow | 2" 45° Elbow |

|---|---|---|---|---|---|

| Nominal Size | 1/4" | 1/2" | 3" | 6" | 2" |

| Pressure Rating (psi) | 150–300 | 150–300 | 80–150 | 30–80 | 150–300 |

| Weight (g) | 68 | 112 | 460 | 1120 | 320 |

| Standard | ANSI B16.11 | ANSI B16.11 | DIN 2605 | ASME B16.9 | ANSI B16.11 |

| Finish | Black/Galv. | Black/Galv. | Brushed/Stainless | Galv./Epoxy | Black/Galv. |

| Application | Instrumentation, Oil | Water, Gas | Exhaust | Industrial Mainline | Municipal, Oil |

Interactive Chart: Technical Parameter Trends

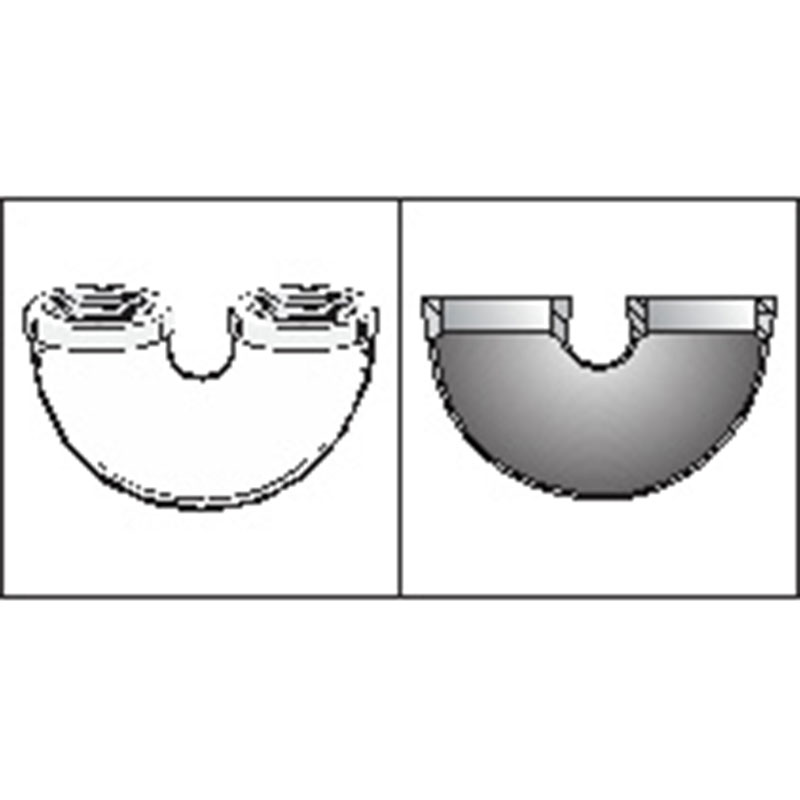

5. Product Focus: 180 Degree Elbow Black or Galvanized

- Product Name: 180 Degree Elbow Black or Galvanized

- Available Sizes: 1/4" to 6"

- Material: Malleable Iron (ASTM A197) / Steel (ISO 49)

- Finish: Black (Anti-rust Paint) or Hot Dip Galvanized (ISO 1461)

- Connection: NPT Threaded, Complies with ANSI/ASME B16.3

- Applications: Water, gas, petroleum, high-pressure and corrosive systems

- Certifications: ISO 9001, ISO 14001, ANSI, SGS batch tested

- Lifespan: 30+ years in indoor service, 12–18 years outdoors (galvanized)

Comparison: 180 Degree Elbow Black vs. Galvanized (Key Performance)

Key Product Highlights

- Full compliance with ISO 49, ANSI B16.3, ANSI B1.20.1 standards.

- Galvanized models offer up to 40% longer corrosion-proof life compared to painted black elbows.

- Certified for potable water (lead-free), also meets requirements for hazardous/industrial pipelines.

- Pannext’s automated inspection logs results for each batch, ensuring traceability and quality consistency.

6. Typical Applications & User Experiences

1 4 npt 45 degree elbow and its derivatives underpin safe, flexible, and cost-effective fluid distribution in:

- Petrochemical Refineries: Corrosion-resistant profiles and precise NPT threading minimize shutdowns, maximizing uptime in aggressive process lines.

- Municipal Water Supply: Galvanized elbows prevent scale buildup, offering secure redirection in both mainstream and district branch networks.

- HVAC and Compressed Air: Their tight leak-proof fit mitigates air/moisture loss in precision pneumatic deployments.

- Automotive Exhaust and Fuel Systems: Stainless or special alloy 3" and 6" elbows withstand long-term vibration and heat cycles.

- Metallurgy: Used to handle superheated/abrasive slurries in steel production with 1 4 npt 45 degree elbow variants.

Selected Customer Case

Challenge: System leakage and corrosion in a 2000m process line network.

Solution: Replaced standard elbows with galvanized 1 4 npt 45 degree elbow and 2 45 degree elbow from Pannext.

Result: Reduced maintenance costs by 32%, MTBF extended from 11 to 19 months, ROI within 8 months (source: company O&M log 2023).

7. Industry Benchmarks & Company Authority

- Pannext Fittings—30+ years in global pipe fitting manufacturing, certified to ISO 9001:2015, ISO 14001:2015.

- Partnerships with Sinopec, Veolia Water, Honeywell.

- 100% conformance inspections, serial-batch traceability, and SGS third-party test support.

- Products referenced in hydraulics engineering reports (ASCE Library).

8. Customization Options

Besides standard products, Pannext offers OEM/ODM services for special alloys (SS304/316, CuNi, etc.), custom tapers, and specialty thread/pressure classes. Short-run custom prototyping and Kitting for modular project needs are available within 14-21 working days on request.

- Custom angled bends (22.5°, 60°), larger/smaller bores

- Threaded, groove, or flanged connections

- Zinc-nickel or epoxy powder coating for aggressive environments

- Barcode labeling and full traceable documentation

9. Delivery & Warranty

- Production Cycle: Standard SKUs 3–7 days, custom parts 14–21 days

- OEM packaging, pallet/crate/box logistics service

- 12-month quality guarantee—free replacement for manufacturing faults

- Dedicated after-sales technical support, 24h response commitment

10. Technical FAQ: 1 4 NPT 45 Degree Elbow & Allied Terminology

11. References & Further Reading

Post time: Jul-29-2025