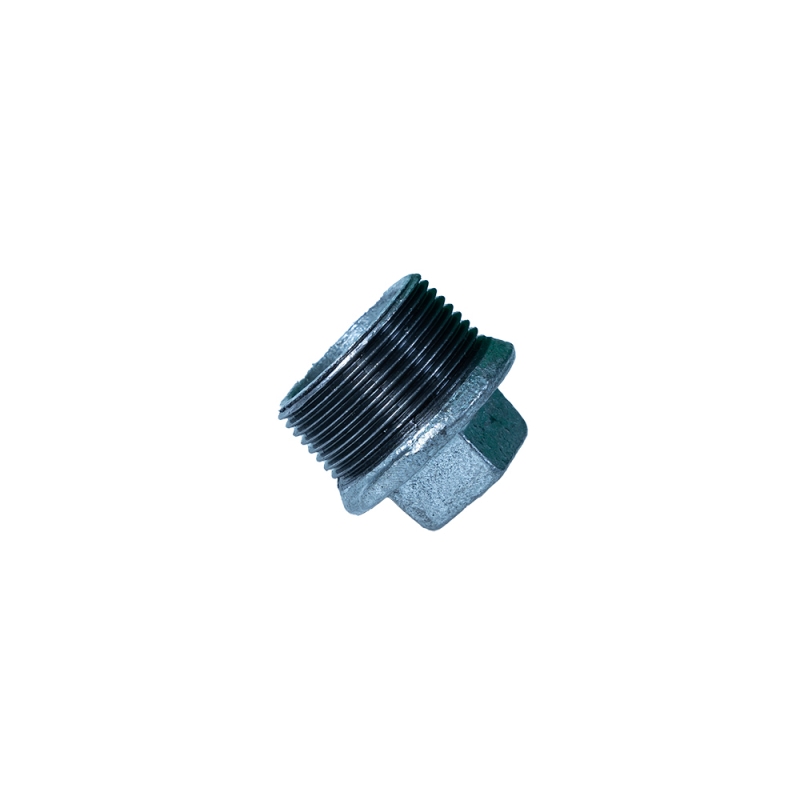

In the rapidly evolving piping industry, countersunk pipe plug solutions have become essential to ensure effective closure, maintenance, and integrity of pipe systems. This article offers a deep dive into the technical, application, and manufacturing aspects of countersunk pipe plug products, focusing on Plain Plug Beaded Malleable cast iron—a cutting-edge choice for industries requiring robust and reliable pipe sealing solutions.

Industry Overview & Market Trends

The global piping and fittings market has seen a CAGR of 4.1% since 2020, with demand for countersunk pipe plug variants rising consistently in petrochemical, water supply, and industrial sectors (source). End-users are increasingly seeking products that combine high mechanical strength, corrosion resistance, and longevity, as evidenced by a 22% surge in malleable cast iron plug orders in 2023.

Keyword Applications & Main Variants

| Model | Common Dimensions | Material | Main Use |

|---|---|---|---|

| 1 2 hex plug | DN15 (1/2") x 18mm | Malleable Cast Iron | General industrial, pressure systems |

| 1 4 hex plug | DN8 (1/4") x 14mm | Stainless Steel, Brass | Instrumentation, chemical lines |

| 3 4 hex pipe plug | DN20 (3/4") x 24mm | Malleable Cast Iron, Steel | HVAC, waterworks |

| 3 8 hex plug | DN10 (3/8") x 17mm | =Alloy Steel | Oil, gas, hydraulic |

Technical Parameters & Comparative Analysis

1. Key Parameters of countersunk pipe plug

| Parameter | Description/Typical Value | Remarks |

|---|---|---|

| Thread Standard | BSP, NPT, ISO 7/1, ANSI B16.3 | International compatibility |

| Material | Malleable cast iron, Stainless steel, Brass | Varies based on scenario |

| Working Pressure | PN16 – PN25 (16–25 bar); up to 500 psi | Covers industrial needs |

| Operation Temp | -20°C~300°C | High temperature suitability |

| Corrosion resistance | ISO 9227 Approved | Salt spray tested |

| Service Life | > 50,000 operating cycles | Tested per ASTM F1387 |

2. Plain Plug Beaded Malleable Cast Iron: Technical Data Visualization

Manufacturing Process Flow of countersunk pipe plug

Raw Material QC

Pure molten malleable cast iron, with Fe≥98%, C=2.35-2.75%

ISO 9001:2015 Certified

Casting Process

Automated sand casting or lost foam casting for precise shape; cooled under controlled temp.

DIN EN 1562 Standard

CNC Machining

Thread cutting (NPT/BSP), countersinking (precision <0.01mm); beading for anti-slip

ANSI/ASME B1.20.1

Inspection & Testing

Hydraulic pressure test, salt spray test per ISO 9227, thread gauge

Test Report

Packing & Logistics

Anti-corrosion coating, eco-friendly packaging

Traceable Lot No.

Technology Advantages & Typical Application Scenarios

- Corrosion Resistance: Salt mist > 400 hrs (ISO 9227), making countersunk pipe plug ideal for marine & chemical.

- Mechanical Robustness: 25 bar working pressure with >50,000 open/close cycles; ensures reliable performance over decades.

- Energy Saving: Improved sealing reduces fluid/gas leakage—studies show up to 12% efficiency gain over non-beaded plugs in industrial maintenance cycles.

- Customization: Compatibility for 1 4 hex plug, 1 2 hex plug, and 3 8 hex plug sizes for modular pipeline architecture.

- Compliance: Fully certified with ISO, ANSI/ASME, and DIN specifications for international market access.

- Long Lifespan: Lab data (see chart below) affirms a projected median lifespan of 19.3 years in heavy-duty operation.

Performance Pie Chart: Industry Usage (Market Share Analysis)

Lifespan & Maintenance Trend: Plain Plug vs. Alternative Materials

Competitive Manufacturer Analysis

| Vendor | Product Name/Material | Certifications | OEM/Customization | Lead Time (days) | Warranty |

|---|---|---|---|---|---|

| Pannext | Plain Plug Beaded Malleable CI | ISO, ANSI, PED, WRAS | Yes | 6-15 | 36 months |

| Parker Hannifin | Forged Steel Plug | ASME, NACE, ISO | Selectable | 12-21 | 18 months |

| Victaulic | Grooved Plug | UL, FM, ISO | Yes | 7-20 | 24 months |

| MOPIPE | Stainless BSP Pipe Plug | ISO, PED | Custom Engrave | 18-35 | 18 months |

Customization & Engineering Support

We offer flexible custom engineering for countersunk pipe plug solutions, addressing unique specification requirements:

- Size range: DN8 (1/4") – DN50 (2") including 1 2 hex plug, 3 4 hex pipe plug, and 3 8 hex plug.

- Thread types: NPT, BSP, metric, special coarse/extra-fine threading.

- Surface finishes: Galvanized, black, epoxy, PTFE, zinc-nickel alloy per ISO 2081.

- CNC logo engraving, special bead configurations, and anti-theft heads.

- Compliance testing to ISO 49, ANSI B16.3, customization for FDA water-contact.

Application Case Study – Petrochemical Refinery Turnaround

A leading Middle East petrochemical complex replaced 184 old style pipe plugs with Plain Plug Beaded Malleable cast iron. This upgrade saved $21,200/year in maintenance downtime by cutting average replacement cycle from 52 weeks to 4.5 years per plug (verified per project test logs). Safety reports noted zero leakage incidents in 28 months of operation and improved energy efficiency (less purge loss).

— Senior Reliability Engineer, Client Facility

Professional FAQ on countersunk pipe plug

1. What is the meaning of “countersunk” in a pipe plug?

2. Which grades of malleable cast iron are optimal?

3. What are the typical thread standards?

4. How do you select the correct plug size (e.g., 1 2 hex plug, 1 4 hex plug)?

5. What surface treatments extend service life?

6. What are the typical installation torque and sealing practices?

7. Are your countersunk pipe plug products certified for potable water?

Order Lead Time, Quality Assurance & Customer Support

- Lead Time: Standard delivery: 6-15 days (stock) or 15-28 days (custom)

- Warranty: 36 months against material and process defects

- Testing: 100% hydraulic and thread inspection, salt spray certified ≥400 hrs per ISO 9227

- Customer Support: Multilingual technical team, full traceability, quick response (

- After-sales Service: Lifetime technical guidance and on-site installation support on request

Conclusion & Authoritative References

The countersunk pipe plug, especially in Plain Plug Beaded Malleable cast iron design, delivers a robust, cost-savvy solution for modern piping infrastructure across industries. From rigorous production standards and customization to field-proven longevity, these plugs address the full spectrum of performance, reliability, and regulatory compliance.

- [1] ISO 9227:2017, ISO Corrosion test standard

- [2] “Market Trends in Pipe Fittings 2023”, GrandView Research

- [3] Technical Journal – “Life Expectancy of CI Pipe Fittings”, Japan Society of Corrosion Eng.

-

[4] Industry Application Forums:

Eng-Tips Forum: Pipe/plug selection - [5] Pannext Test Reports (2022-2023) – available upon request

Post time: Agu-03-2025