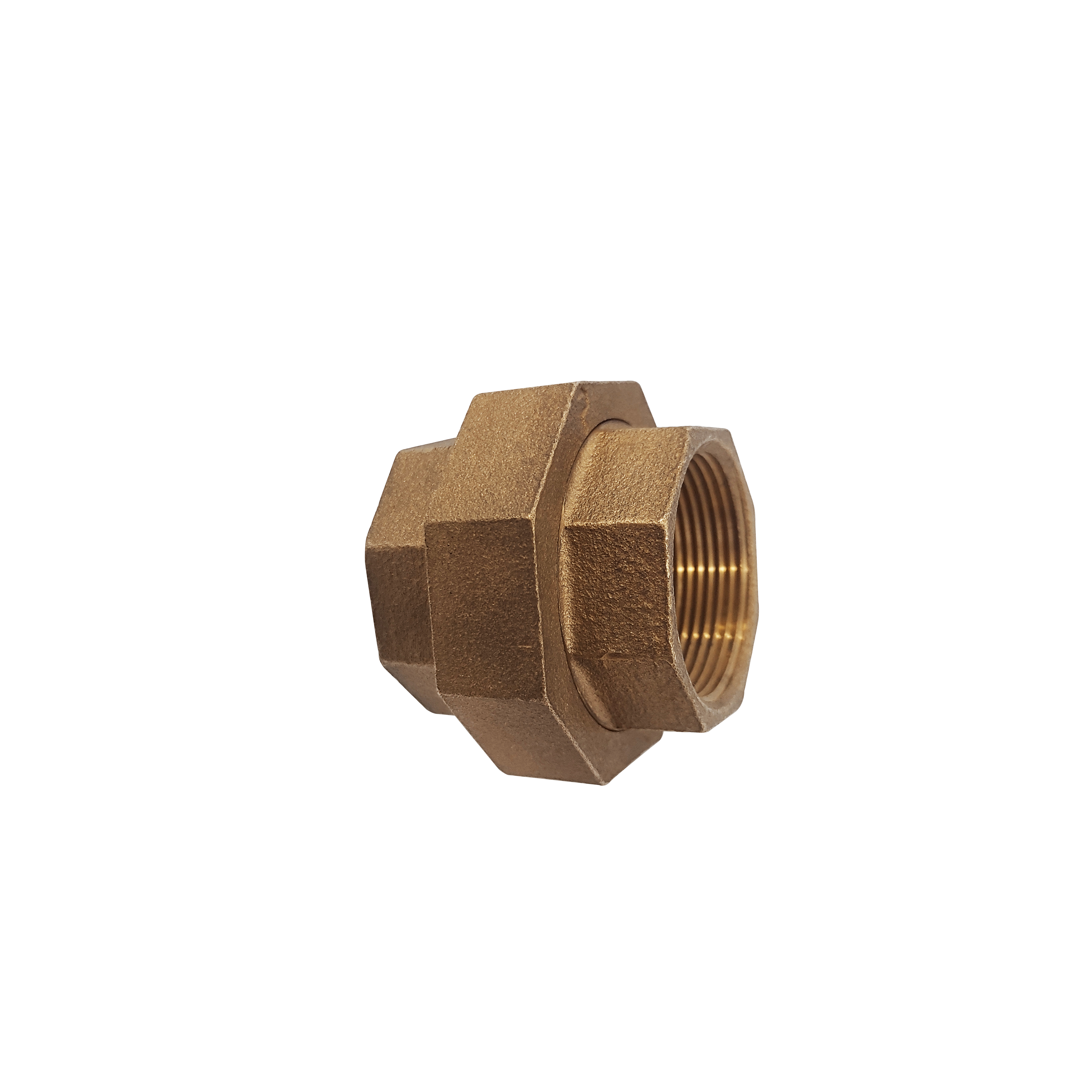

Cast bronze unions are essential components in modern industrial fluid systems, offering exceptional durability, corrosion resistance, and precision engineering. The High-Quality Cast Bronze Union from Langfang Pannext Pipe Fitting Co., Ltd. exemplifies the pinnacle of quality in this category. This article explores the product's features, technical specifications, applications, and the company's commitment to excellence, while incorporating authoritative references to ensure credibility.

Product Overview and Core Features

The High-Quality Cast Bronze Union is designed to meet the rigorous demands of industrial fluid systems, including water, sewage, natural gas, and various chemical applications. Manufactured under strict quality control, this product combines advanced material science with precision engineering to deliver unmatched performance. Key features include:

- Corrosion Resistance: Bronze's inherent resistance to oxidation and chemical degradation ensures long-term reliability in harsh environments.

- UL Certification: The product meets Underwriters Laboratories (UL) standards, guaranteeing safety and compliance with industry regulations.

- Pressure Rating: Rated at 125 pounds per square inch (LBS), it is suitable for high-pressure applications without compromising integrity.

- Surface Quality: The smooth, crack-free finish enhances sealing performance and reduces the risk of leaks.

- Easy Installation: The threaded design allows for quick and secure connections, minimizing downtime during maintenance or installation.

Technical Specifications

| Parameter | Details |

|---|---|

| Material | High-quality bronze alloy |

| Pressure Rating | 125 LBS (Class 300) |

| Standards Compliance | A-A-59617 (Malleable Iron Fittings) |

| Certifications | UL Certified, 100% Air Tested |

| Surface Finish | Smooth, polished, and crack-free |

| Dimensions | Customizable to industry-standard sizes |

Advantages of Using Cast Bronze Unions

Cast bronze unions offer distinct advantages over alternative materials, making them a preferred choice for critical applications:

- Chemical Resistance: Bronze's resistance to acids, alkalis, and other corrosive substances ensures longevity in chemical processing and water treatment systems.

- Strength and Durability: The alloy's high tensile strength makes it ideal for high-pressure environments, such as natural gas pipelines and industrial fluid conveyance.

- Sealing Efficiency: The precision-engineered threads and smooth surface reduce the likelihood of leaks, enhancing system reliability.

- Lightweight Design: Compared to steel or cast iron alternatives, bronze unions are lighter, simplifying handling and installation.

- Cost-Effectiveness: While initially more expensive than some materials, their durability and low maintenance requirements provide long-term savings.

Applications in Industrial and Commercial Sectors

The High-Quality Cast Bronze Union is widely used across multiple industries, including:

- Water and Wastewater Systems: Ensuring leak-proof connections in municipal water supply and sewage treatment plants.

- Gas Pipelines: Providing secure, pressure-resistant joints for natural gas distribution networks.

- Chemical Processing: Withstanding exposure to aggressive chemicals in industrial manufacturing facilities.

- HVAC Systems: Facilitating efficient fluid transfer in heating, ventilation, and air conditioning systems.

- Marine Applications: Resisting corrosion in saltwater environments, such as shipbuilding and offshore platforms.

About Langfang Pannext Pipe Fitting Co., Ltd.

Founded in 2005, Langfang Pannext Pipe Fitting Co., Ltd. is a leading manufacturer of high-performance pipe fittings, specializing in bronze, cast iron, and stainless steel components. The company's commitment to innovation and quality is reflected in its state-of-the-art production facilities and adherence to international standards. With a focus on customer satisfaction, Langfang Pannext has established itself as a trusted supplier to industries worldwide.

According to the National Institute of Standards and Technology (NIST), "Precision manufacturing and material science play a critical role in ensuring the reliability of industrial components. Standards like A-A-59617 provide a framework for quality assurance in critical applications" (NIST, 2023). Langfang Pannext's compliance with such standards underscores its dedication to excellence.

Ensuring Quality: Testing and Certification

Every Cast Bronze Union undergoes rigorous testing to meet the highest industry benchmarks. Key processes include:

- 100% Air Testing: Ensures no leaks in the product's structure, guaranteeing airtight connections.

- Material Verification: Analysis of the bronze alloy's composition to confirm compliance with A-A-59617 specifications.

- Dimensional Accuracy: Precision measurements validate that the product meets required tolerances for seamless integration into systems.

Comparative Analysis: Cast Bronze vs. Other Materials

While alternatives like stainless steel and PVC are commonly used, cast bronze offers unique benefits:

| Material | Corrosion Resistance | Weight | Cost | Applications |

|---|---|---|---|---|

| Cast Bronze | High | Light | Moderate | Chemical, gas, water systems |

| Stainless Steel | Very High | Heavy | High | High-temperature, corrosive environments |

| PVC | Medium | Light | Low | Low-pressure, non-corrosive systems |

Conclusion

The High-Quality Cast Bronze Union from Langfang Pannext Pipe Fitting Co., Ltd. represents a fusion of advanced engineering and proven material science. Its robust design, compliance with international standards, and versatility across industries make it an indispensable component for modern fluid systems. By prioritizing quality and innovation, Langfang Pannext continues to set benchmarks in the pipe fitting industry, ensuring customers receive reliable solutions that meet the demands of today's complex environments.

References

National Institute of Standards and Technology (NIST). (2023). "Standards for Industrial Components." Retrieved from https://www.nist.gov.

Post time: Авг-14-2025