Overview: Malleable cast iron—encompassing renowned subtypes like black heart malleable cast iron and ferritic malleable cast iron—remains fundamental to heavy-duty mechanical engineering, pipe unions, and fittings across oil & gas, waterworks, and metallurgy industries. In 2023, the global malleable cast iron market size reached $5.2 billion, with steady CAGR growth projected at 4.1% through 2028 (MarketsandMarkets).

High precision malleable cast iron foundry operation (source: Pannext Fittings)

High precision malleable cast iron foundry operation (source: Pannext Fittings)

1. Industry Trends: Malleable Cast Iron Evolution & Market Insights

- Scientific property: Malleable cast iron combines significant ductility (>10%) with tensile strength (400–570 MPa) and impact resistance due to its microstructure.

- Key sectors: Oil & Gas, Plumbing, Fire Protection, Agriculture, Petrochemicals, and Metallurgy.

- Latest trend: Surge in demand for corrosion-resistant fittings and customizable alloys for niche industrial applications.

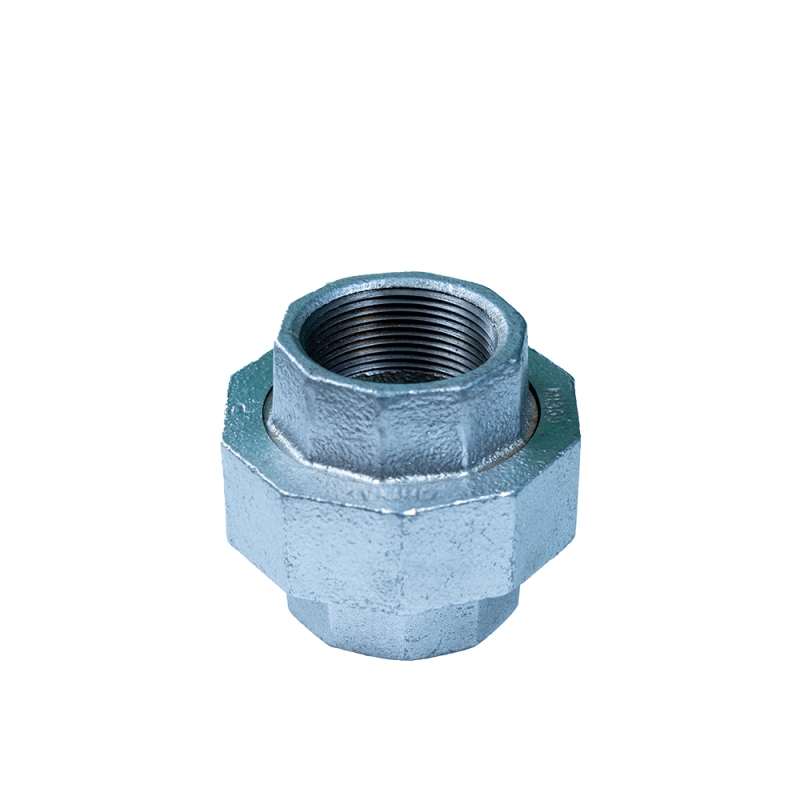

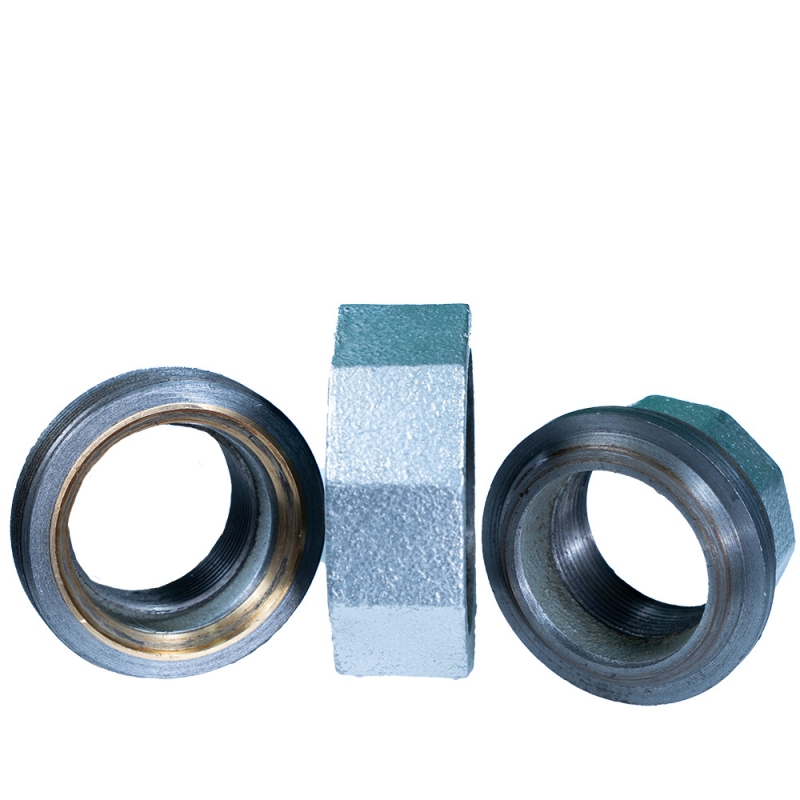

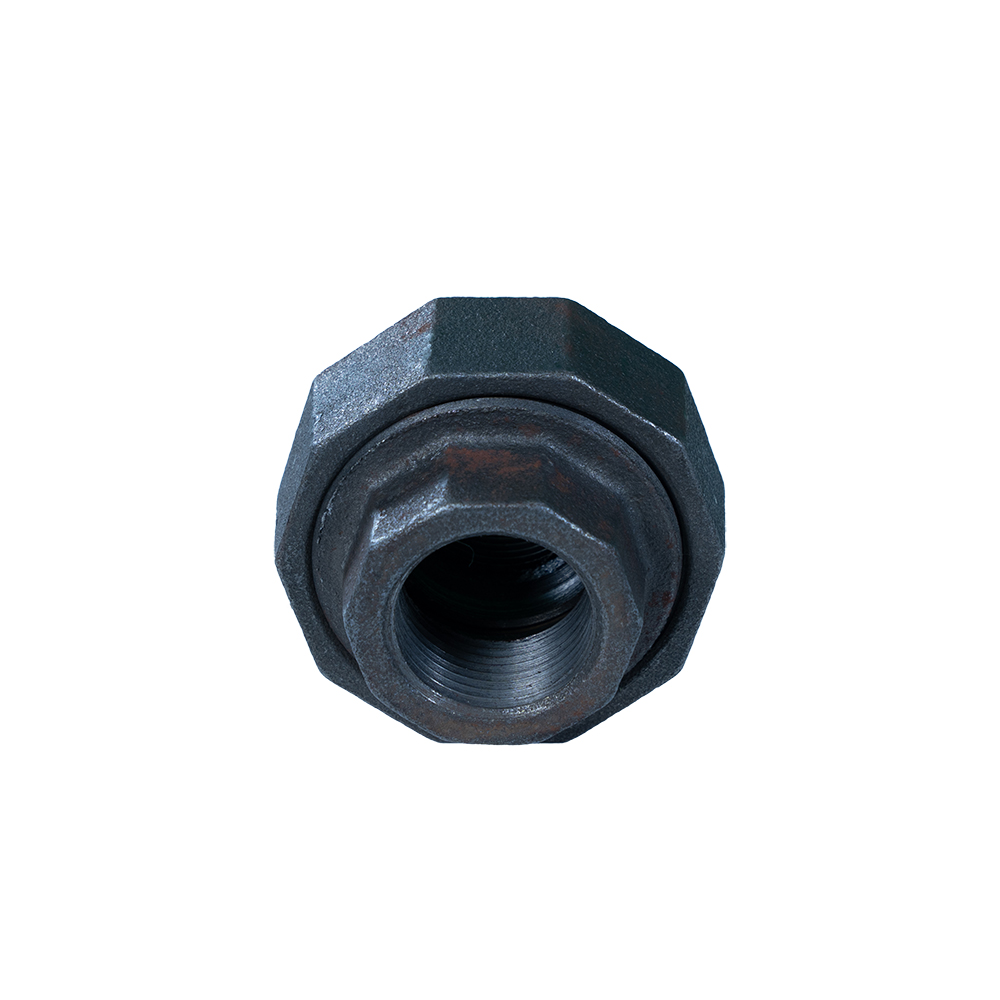

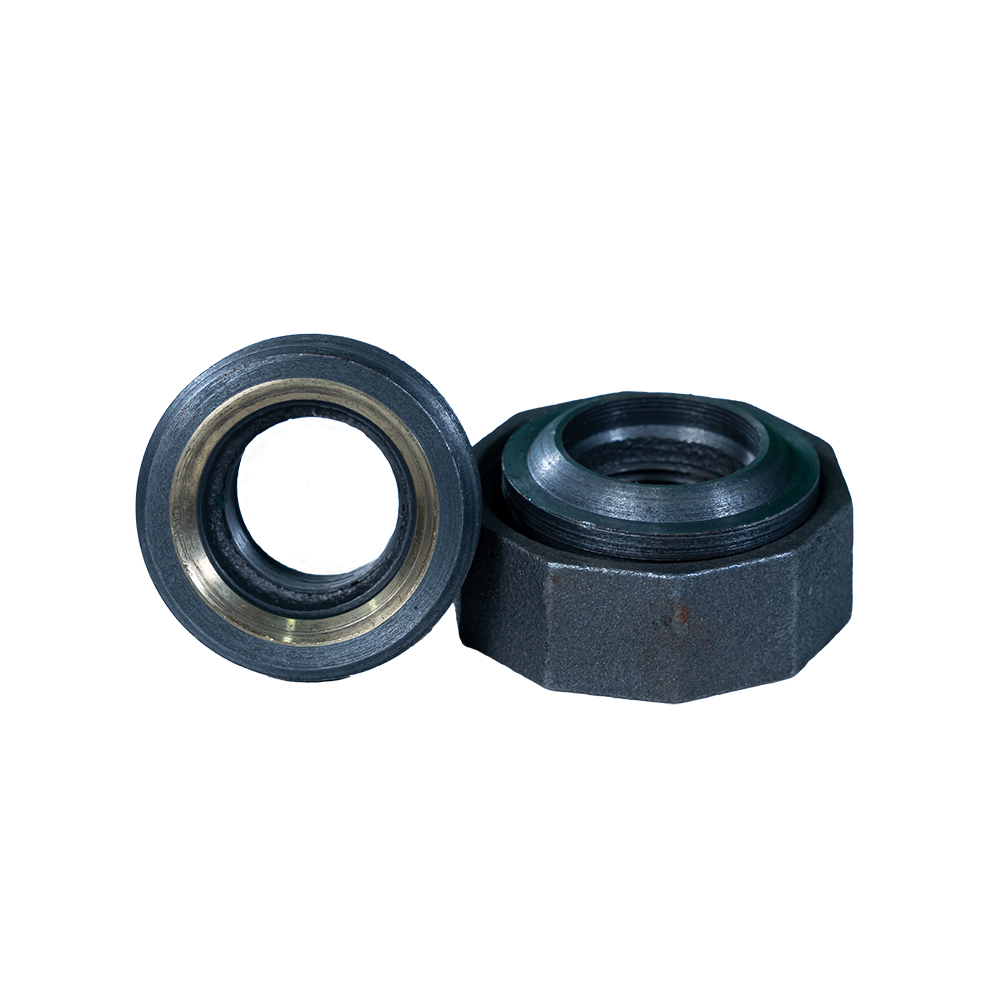

- Product focus: High Quality Union with brass seat integrates malleable cast iron with a precision brass seat for optimal sealing, durability, and adaptability in aggressive media and pressure environments.

Malleable cast iron union sample with brass seat interface

Malleable cast iron union sample with brass seat interface

2. Key Technical Parameters: Comparative Table

| Parameter | Black Heart Malleable Cast Iron | Ferritic Malleable Cast Iron | Ductile Cast Iron (Reference) |

|---|---|---|---|

| Carbon Content (%) | 2.2 – 2.9 | 2.0 – 2.7 | 3.2 – 4.0 |

| Tensile Strength (MPa) | 350 – 480 | 400 – 570 | 400 – 700 |

| Yield Strength (MPa) | 220 – 350 | 250 – 390 | 300 – 520 |

| Elongation (%) | 5 – 10 | 10 – 16 | 2 – 18 |

| Impact Toughness (J/cm²) | >9 | >14 | >12 |

| Corrosion Resistance | Medium | High | Medium–High |

| Applications | Pipe Unions, Valves | Pressure Fittings, Unions | Pipes, Larger Fittings |

3. Advanced Manufacturing: Malleable Cast Iron Process Flow

High-purity pig iron, steel scrap, alloys

850–950℃ in controlled atmosphere for graphitization.

Turning, threading, facing (tight tolerances, ISO 49 standards)

Brass Seat Fit-up

Ensures metallic sealing, corrosion resistance

Hydrostatic, tensile & leak tests, ISO/ANSI compliance

- Primary Certification: ISO 9001:2015, ANSI B16.39, UL/FM for fire-grade unions

- Corrosion prevention: Special surface passivation/galvanization for cast iron union products enhances life up to 15 years in saline media

Precision machining at malleable iron foundry under ISO quality guidelines

Precision machining at malleable iron foundry under ISO quality guidelines

4. Product Feature Focus: High Quality Union with Brass Seat

- Body: Malleable cast iron (grade: EN-GJMB-350-10, per EN 1562) + precision brass sealing seat

- Connection: Female BSP/NPT threads, G1/2" – G4" available

- Operating Pressure: 1.6–2.5MPa (232–363 psi)

- Temperature Range: -20°C to 180°C

- Testing: 100% factory hydrostatic and pneumatic seal tests

- Detection standard: ISO 49, EN standards, ANSI B16.39

- Surface: Black, zinc galvanized, hot-dip galvanized

- Life cycle: >20,000 operation cycles

Cast iron union with brass seat in water supply installation.

Cast iron union with brass seat in water supply installation.

| Parameter | Value/Range | Description |

|---|---|---|

| Size | 1/2" – 4" (DN15–DN100) | Available in BSP & NPT Thread |

| Shell Pressure Test | 24 bar | Conforms to ISO 49, EN 10242 |

| Material | Malleable Cast Iron + CW617N Brass | High strength, corrosion resistance |

| Process | Casting + CNC Machining | Tight tolerance, smooth threads |

| Thread Accuracy | Class A (ISO 7-1) | Max leak-tightness for pressurized media |

| Coating | Galvanized / Black | Extra corrosion protection |

| Warranty | 2 Years | Replace/repair under service contract |

5. Manufacturer Comparison (2024): Malleable Iron Foundry Selection Guide

| Company | Certifications | Annual Output (tons) | OEM/ODM | Main Markets | Key Feature |

|---|---|---|---|---|---|

| Shandong Pannext Fittings | ISO 9001:2015, UL/FM, WRAS | 65,000 | Yes | EU, NA, MENA | Automated foundry; full-scale CNC workshop |

| Jinan Linzhou | ISO, SGS | 42,000 | Yes | Asia, Africa | Standard pipeline unions |

| Hebei Runda | ISO, CE | 37,000 | Partial | EU, Mid-East | Economical solutions |

| Mueller US | UL/FM, ISO | 28,000 | No | USA & Canada | Fire system unions |

Market Note: Choosing a malleable iron foundry with full material traceability and ISO certifications is critical for regulated industries. Leading players like Shandong Pannext combine automation and CNC finishing, ensuring premium standards across global markets.

6. Customization Capability & Delivery Support

- Custom thread (NPS, NPT, BSP, metric) & face-to-face dimensions for unique installation requirements

- Compatible with brass, alloy steel, or special polymer seats

- Optional powder or epoxy-based surface treatment for aggressive chemical applications

- OEM/ODM: Corporate logo, packaging, custom kits, individual barcode tracking

- Standard Delivery Cycle: 25–35 days ex-works (bulk orders); Priority express: 7–12 days (project supply)

- Warranty: 24 months as per supplied technical specification, with extended after-sales for contractual clients

- 24/7 Technical support by certified engineers, rapid spare parts delivery

7. Typical Application Scenarios & Competitive Advantages

- Petrochemical pipelines – Anti-corrosion property and high seal integrity reduce leak risks (field data: external leak rate <0.01%/yr)

- Municipal waterworks – Withstand daily valve cycling and pressure fluctuations

- Firefighting sprinkler system – UL/FM-certified cast iron unions offer robust response under thermal expansion

- Metallurgy/Steel plants – Long-term resistance to vibration and mechanical stress

- Agricultural irrigation – High resistance to sandy and mineral-rich fluids

- Building HVAC – Maintains sealing integrity under repeated temperature cycles

Case Study: Oil Refinery Pipe Network Modernization

- Project: Jiangsu Petrochemical (China, 2023)

- Requirement: 4,200 sets of 2" malleable cast iron unions, petro-resistant brass seat

- Outcome: 0 installation failure in hydrotest, projected service life >15 years, customer downtime reduced by 22% compared to cast steel unions.

- Client Feedback: “Pannext’s unions provided consistent leak-free performance, with true thread fit.”

8. Frequently Asked Questions (FAQ) on Malleable Cast Iron Unions

9. Conclusion & Further Reading

Malleable cast iron unions—particularly those employing a brass seat—are an industry benchmark for reliable, corrosion-resistant, and cost-effective pipeline solutions. Top suppliers ensure compliance with international standards such as ISO 49, provide thorough QC, and demonstrate their expertise and reputation via proven performance and customer success stories.

References:

- MaterialsToday.com: The Role of Malleable Iron in Modern Plumbing

- ASM International: “Malleable Cast Iron: Metallurgy & Applications”

- Eng-Tips Forum: Pipe Fitting & Malleable Iron Discussions

- ScienceDirect: Recent Advances in Malleable Cast Iron Alloys

For detailed specs & engineering support, visit High Quality Union with brass seat.

Post time: Juli-28-2025

This is the first article