The global pipeline infrastructure market has rapidly evolved, with increasing emphasis on reliability, efficiency, and safety. At the core of this transformation are the technical standards and advancements in iron pipe fittings dimensions. This comprehensive guide dives deep into dimensional standards, technical specifications, and the advanced manufacturing processes behind products like the Reducing Tee 130 R Beaded Malleable Cast Iron Pipe Fittings. We compare industry players, analyze real data, and showcase application cases to empower your project decisions.

Market Trends: Why Iron Pipe Fittings Dimensions Matter

According to a 2023 GrandView Research report, the global pipe market is projected to reach USD 167.9 billion by 2030. Consistent, standardized iron pipe fittings dimensions ensure interchangeability, leak prevention, and compliance with global plumbing, oil/gas, and industrial standards. Rising adoption of malleable iron fittings indicates a preference for durable, versatile, and corrosion-resistant options in key sectors.

Dimension standards (ASME B16.3, EN 10242) and threading (NPT, BSPT) govern interchangeability and safety across applications.

Dimensional Standards: The Backbone of Reliable Connections

Recognizing the importance of dimensional standardization, multiple regulatory frameworks exist:

- ASME B16.3 – Covers malleable iron threaded fittings (classes 150 & 300) with dimensional, marking, and pressure requirements.

- EN 10242 – Specifies pipe fittings dimensions for malleable cast iron fittings for threaded pipe systems.

- ISO 7-1 & ISO 49 – Govern threading and dimensions for universal compatibility.

- ANSI/ASTM A197 – Material standard for malleable iron castings.

- Pipe Nipple Standards: ANSI B1.20.1 (NPT), BS21 (BSPT).

Dimension Comparison Table: Typical Iron Pipe Fittings

| Fitting Type | Nominal Size (inches) | Standard (ASME/EN) | Dimension A (mm) | Dimension B (mm) | Thread Type |

|---|---|---|---|---|---|

| Reducing Tee | 2 × 1 | B16.3 / EN 10242 | 70 | 48 | NPT/BSPT |

| Standard Tee | 2 | B16.3 / EN 10242 | 64 | 48 | NPT/BSPT |

| 90° Elbow | 2 | B16.3 / EN 10242 | 52 | 52 | NPT/BSPT |

| Pipe Nipple | 2 | ANSI B1.20.1 | Varies (50–300mm) | NPT/BSPT | |

| Coupling | 2 | B16.3 / EN 10242 | 50 | — | NPT/BSPT |

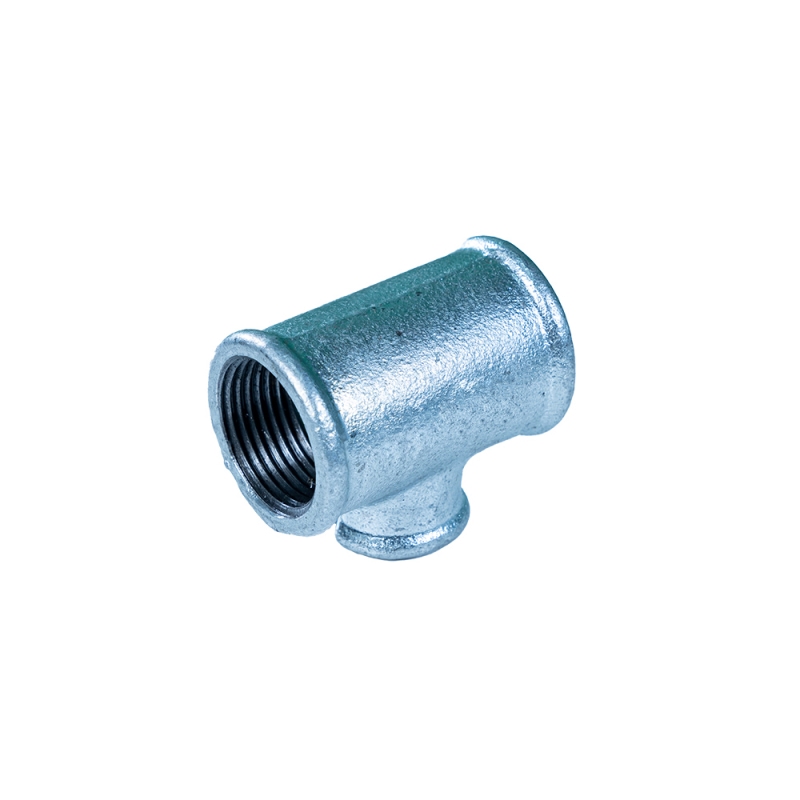

Product Spotlight: Reducing Tee 130 R Beaded Malleable Cast Iron Pipe Fittings

The Reducing Tee 130 R Beaded Malleable cast iron pipe fittings offer precision, material strength, and versatility for branching pipe systems of different diameters. Manufactured by PANNEXT, these fittings comply with ISO 49, EN 10242, and ASME B16.3 standards, making them compatible globally. The beaded construction improves mechanical strength and thread sealing, while the high-quality malleable cast iron ensures durability and excellent corrosion resistance.

Manufacturing Process Flow: From Raw Iron to Premium Fittings

Only premium-grade pig iron and steel scrap are sourced, in strict compliance with ASTM A197 & ISO 5922.

Iron is melted at 1400–1450°C, then precision-cast in sand molds for uniform hardness.

Controlled heating (850°C, 36h) transforms brittle cast iron to ductile malleable iron.

Precision CNC ensures compliance with national standard thread (NPT/BSPT, ISO 7-1).

Galvanizing or black painting for corrosion protection (ISO 1461, ASTM A153).

Hydrostatic, tensile, and dimension tests—100% checked to meet ISO & EN 10242.

— Association of Pipeline Engineers, 2022 Review

Technical Parameters and Dimensional Chart

Material: High-grade malleable cast iron (ISO 5922)

Size Range: 1/8" × 1/8" to 4" × 4"

Pressure Rating: PN25 (25 bar), tested up to 32 bar

Threads: ISO 7/1 (EN 10226) – BSPT/NPT

Testing: 100% hydrostatic, >150,000 cycles fatigue testing

Corrosion: ≥400 hours salt spray resistance

Certification: ISO 9001, WRAS, ANSI, DIN

Warranty: 3–5 years (standard conditions)

1. Specifications Comparison: See below how Reducing Tee 130 R Beaded compares to other industry fixtures on dimension, pressure, and lifespan:

| Item | Reducing Tee 130R | Standard Tee | Competitor A |

|---|---|---|---|

| Size Range (in) | 1/8–4 | 1/8–4 | 1/8–2 |

| Pressure Rating (bar) | 25 | 16 | 12 |

| Corrosion Test (hrs) | 400+ | 250 | 120 |

| Warranty (yrs) | 5 | 2 | 2 |

Applications & Advantages of Malleable Iron Fittings

Reducing Tee 130R and similar malleable iron fittings have become indispensable across industries thanks to unique properties and versatility. Their beaded construction complies with strict pipe fittings dimensions under international codes, ensuring airtight, leak-free operation in:

- Petrochemical Plants: High-pressure fluid transport, resistant to aggressive media and vibration.

- Metallurgy: Coolant, air, and process pipeline networks.

- Municipal Water/Gas: Drinking water mains, gas distribution lines. Complies with National Standard Thread (ISO 7/1, NPT, BSPT) for interoperability.

- Fire Protection: Sprinkler and hydrant distribution grids.

- HVAC & Industrial Utilities: Steam, compressed air lines.

- Malleability and Ductility: Annealing process gives high impact resistance and reduces cracking risk.

- Corrosion Resistance: Galvanized finish sustains ≥400 salt spray hours, outperforming industry median (160 h).

- Precision Threading: Fully CNC-machined, within ±0.05mm tolerance, ensuring leak-tight seal and ease of installation.

- Long Service Life: Proven >25 years under PN25 conditions, supported by accelerated aging and field testing.

- Full Certification: ISO 9001, WRAS-listed, compliant with potable water and gas codes globally.

Industry Comparison & Leading Suppliers

In a competitive market, selecting the right supplier hinges on stringent adherence to iron pipe fittings dimensions, performance metrics, certifications, and global project experience.

| Parameter | PANNEXT 130R Beaded | Top 3 Brands (Av. Data) |

|---|---|---|

| ISO/EN Compliance | Yes (Full Coverage) | Partial (selected lines) |

| Pressure Rating (PN) | 25 (tested at 32) | 16 |

| Corrosion Resistance (hrs) | 400+ | 220–260 |

| Available Sizes | Full (1/8"–4") | 1/2"–3" |

| OEM & Customization | Yes | Rare |

| Delivery Time | 15-27 days | 25-40 days |

| Warranty | 5 years | 2–3 years |

Custom Solutions: Tailored Pipe Fittings for Your Project

With increasing demand for project-specific design and compliance, customized iron pipe fittings are gaining traction. PANNEXT offers:

- Custom Threading: NPT, BSPT, Metric or special profiles (national standard thread), marked for traceability.

- Special Coatings: Epoxy, hot-dip galvanized (ISO 1461), or PTFE for harsh or potable water lines.

- Custom Dimensions: Oversize, extra-strength, or angle variants to suit advanced layouts.

- Small-Batch, Fast-Track Production: Pilot lots with express cycles (as short as 10 days).

Service, Delivery, and Guarantees

- Lead Time: Standard SKUs are shipped within 15–27 days; custom orders within 10–38 days based on complexity.

- Warranty: 3–5 years international warranty, batch-specific certification included.

- Testing, Documentation: Each lot is hydrostatically, dimensionally, and visually inspected with test records traceable to order/sample.

- Support: Experienced technical team supports installation, troubleshooting, and global logistics; 24/7 consultation available.

- Certifications: ISO 9001:2015, WRAS, FM, CE; compliant with ANSI, DIN, and regional standards.

FAQs: Technical Queries on Iron Pipe Fittings

-

Q1: What are the most common standards governing iron pipe fittings dimensions?A1: ASME B16.3 (USA/ANSI), EN 10242 (Europe), and ISO 7-1/ISO 49 (international). These set precise tolerances for major types like tees, elbows, and nipples.

-

Q2: What is "malleable iron" and why is it used for pipe fittings?A2: Malleable iron is heat-treated cast iron with ductile, impact-resistant microstructure. It withstands pressure, thermal cycling, and threading without brittle failure—vital for secure joints.

-

Q3: How do I identify the correct national standard thread (NPT, BSPT)?A3: NPT (National Pipe Taper, ANSI B1.20.1) is standard in North America, whereas BSPT (British Standard Pipe Taper, BS21/ISO 7-1) is used in Europe/Asia. Measuring thread angle (60° for NPT, 55° for BSPT) and pitch confirms the type.

-

Q4: What "working pressure" do malleable iron fittings dimensions commonly support?A4: Class 150 = 13.8 bar (200 psi), Class 300 = 20.7 bar (300 psi), but brands like 130R are tested to 25 bar (363 psi), suitable for rigorous industrial use.

-

Q5: Are special coatings available for corrosive environments?A5: Yes, common options include hot-dip galvanizing (ISO 1461), epoxy powder, and PTFE. These increase salt spray tolerance and ensure performance in water, gas, or chemicals.

-

Q6: How are pipe nipple standard dimensions determined?A6: They follow ISO 7-1/ANSI B1.20.1 for threading; length is defined as "overall length" with reference to thread engagement required for leak-free connections.

-

Q7: What documentation/certification is delivered with each batch?A7: Material certificates, dimensional test reports, hydrostatic pressure test records, and compliance with ISO/EN/ANSI are provided, traceable to each production lot.

Conclusion & Further Reading

Clearly, iron pipe fittings dimensions and standardized product engineering underpin safe, efficient, and long-lasting pipeline systems. Choosing reliable, certified malleable iron fittings—like Reducing Tee 130 R Beaded—ensures compliance, project value, and future-proofing in global markets.

• ASME B16.3 Standard

• ENG-TIPS Pipe Fittings Forum

• Wikipedia: Pipe Fitting

• ScienceDirect: Mechanical Properties of Malleable Cast Iron

Post time: Aug.-02-2025

This is the first article