|

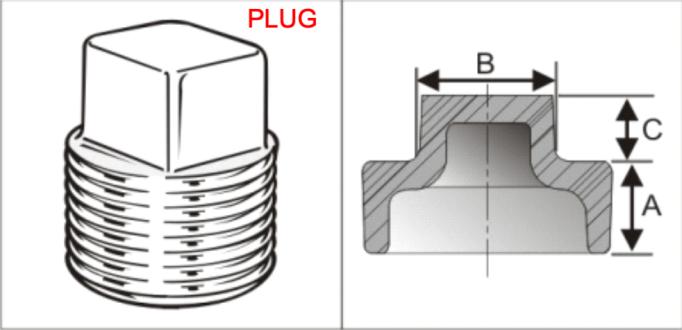

Item |

Ukuran (inch) |

ukuran |

Kasus Qty |

Kasus Khusus |

Bobot |

|||||||||||||||||

|

Nomer |

|

|

A |

|

B | C |

Guru |

batin |

Guru |

batin |

(Gram) |

|||||||||||

| PLG01 | 1/8 | 0.27 | 0.28 | 0.24 |

1400 |

5/bag |

|

1400 |

5/bag |

8.8 |

||||||||||||

| PLG02 | 1/4 | 0.41 | 0.37 | 0.28 |

1200 |

5/bag |

|

1200 |

5/bag |

17.6 |

||||||||||||

| PLG03 | 3/8 | 0.41 | 0.43 | 0.31 |

700 |

5/bag |

|

700 |

5/bag |

28.7 |

||||||||||||

| PLG05 | 1/2 | 0.54 | 0.56 | 0.38 |

500 |

5/bag |

|

500 |

5/bag |

44 |

||||||||||||

| PLG07 | 3/4 | 0.55 | 0.62 | 0.44 |

300 |

5/bag |

|

300 |

5/bag |

60 |

||||||||||||

| PLG10 | 1 | 0.69 | 0.81 | 0.50 |

200 |

5/bag |

|

200 |

5/bag |

121 |

||||||||||||

| PLG12 | 1-1/4 | 0.71 | 0.93 | 0.56 |

120 |

5/bag |

|

120 |

5/bag |

181.5 |

||||||||||||

| PLG15 | 1-1/2 | 0.73 | 1.38 | 0.62 |

80 |

5/bag |

|

80 |

5/bag |

260 |

||||||||||||

| PLG20 | 2 | 0.76 | 1.31 | 0.68 |

50 |

5/bag |

|

50 |

5/bag |

357.5 |

||||||||||||

| PLG25 | 2-1/2 | 1.07 | 1.50 | 0.74 |

40 |

1/bag |

|

40 |

1/bag |

555 |

||||||||||||

| PLG30 | 3 | 1.38 | 1.68 | 0.80 |

25 |

1/bag |

|

25 |

1/bag |

920 |

||||||||||||

| PLG35 | 3-1/2 | * | * | * |

16 |

1/bag |

|

16 |

1/bag | * | ||||||||||||

| PLG40 | 4 | 1.22 | 2.25 | 0.92 |

14 |

1/bag |

|

14 |

1/bag |

1620 |

||||||||||||

|

1. Teknis: Casting |

6. Bahan: ASTM B62, UNS Alloy C83600; ASTM B824 C89633 |

|

2.Brand:“ P” |

7.Fitting Dimensions: ASEM B16.15 Class125 |

|

3.Product Cap.: 50Ton/ Mon |

8. Utas Standar: NPT selaras karo ASME B1.20.1 |

|

4. Asal: Thailand |

9. Elongation: 20% Minimal |

|

5.Application:Jointing Water Pipe |

10. Kekuwatan Tarik: 20.0kg / mm (minimal) |

|

11.Paket: Ekspor Stardard, Karton Master karo kothak Inner Karton Master: 5 lapisan kertas corrugated |

|

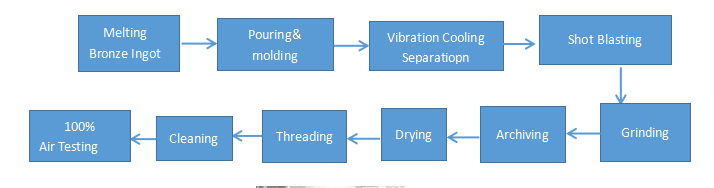

Kita duwe sistem manajemen kualitas sing ketat.

|

Saben potongan kudu dipriksa miturut SOP sing ketat, saka wiwitan bahan mentah sing mlebu menyang proses produk nganti produk rampung sing 100% uji coba banyu sadurunge mlebu ing gudang. |

1.Pemeriksaan Bahan Baku,Njaga Kualitas Bahan sing mlebu |

| 2. Molding 1).Inspecting the tem. of molten iron. 2.Chemical Composition | |

| 3. Rotary cooling: Sawise Casting, katon Inspection | |

| 4. Grinding Katon mriksa | |

| 5.Threading Ing-proses mriksa katon lan Utas dening Gages. | |

| 6. Tekanan banyu 100% Diuji, priksa ora bocor | |

| 7.Package:QC Dipriksa yen cargoes dikempalken padha karo pesenan |

|

Mode |

karo% |

Zn% |

Pb% |

Sn% |

|

C83600 |

84.6~85.5 |

4.7~5.3 |

4.6~5.2 |

4.7~5.1 |

Keep every pipe fitting that our Clients’ received is qualified.

P: Apa sampeyan pabrik utawa perusahaan dagang?

A: Kita minangka pabrik kanthi sejarah +30 taun ing lapangan casting.

P: Apa syarat pembayaran sing sampeyan dukung?

A: TTor L/C. 30% payment in advance, and the 70%balance would be

mbayar sadurunge pangiriman.

Q: Suwene wektu pangiriman sampeyan?

A: 35 dina sawise nampa pembayaran majeng.

Q: Apa bisa njaluk conto saka pabrik sampeyan?

A: Nggih. sampel free bakal kasedhiya.

Q: Pira taun produk dijamin?

A: Minimal 1 taun.

PAWARTA