Headquarters

236 West Guangming Road Langfang, Hebei, China

Contact Information

Tel: 0316-2652671 | Mobile: 0086-15690252169

Email: fanda@pannext-casting.com

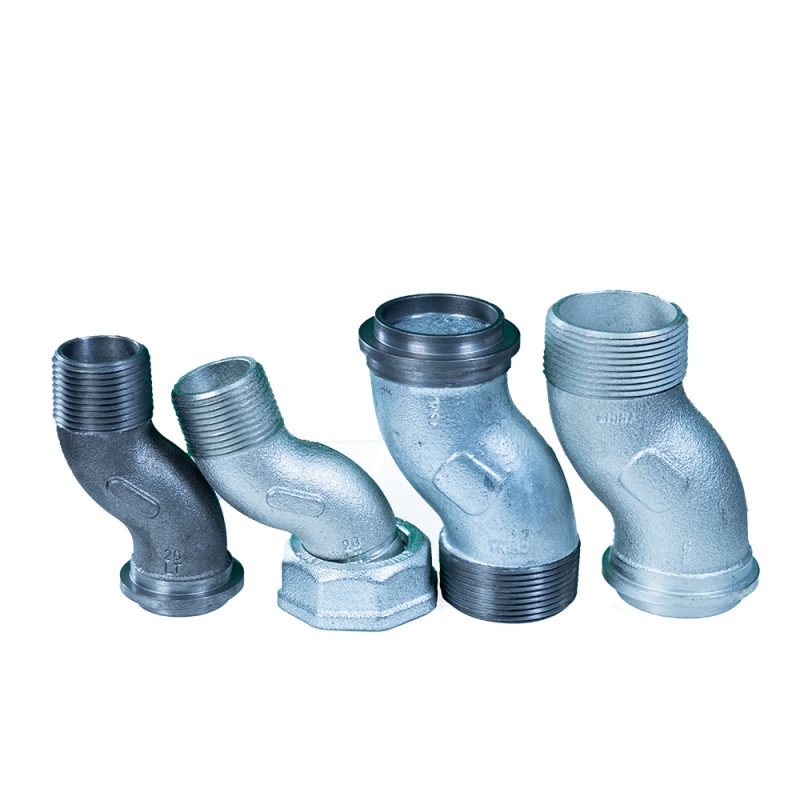

Introduction to Galvanized Quick Connect Fittings

The industrial piping landscape continues to evolve with Galvanized Quick connections emerging as a transformative solution for modern infrastructure projects. These innovative pipe fittings represent a quantum leap from traditional threaded connections, combining the corrosion resistance of hot-dip galvanization with rapid-installation quick-connect mechanisms. As industries increasingly prioritize efficiency, durability, and installation cost savings, Galvanized Quick technology has positioned itself as an essential component in contemporary fluid handling systems.

Developed through advanced CNC machining processes, these fittings maintain precise threading standards (150 Class) while incorporating user-friendly quick-disconnect functionality. The surface treatment—available in both black or hot-dip galvanized finishes—provides exceptional protection against corrosion and environmental degradation. Galvanized Quick solutions are manufactured to meet the exacting requirements of industrial applications where both performance and installation efficiency are critical factors.

Industry Trends in Quick-Connect Fittings

The global market for specialized pipe fittings is projected to reach $128.7 billion by 2028, with quick-connect solutions showing the strongest growth trajectory at an estimated CAGR of 7.2% (Piping Systems International Report, 2023). This surge is primarily driven by four factors:

Labor Cost Reduction

Quick-connect systems reduce installation time by up to 65% compared to traditional threaded connections

Corrosion Resistance

Galvanized coatings extend service life by 3-4× in corrosive environments

Maintenance Efficiency

Quick-disconnect capability reduces system downtime during repairs

Precision Manufacturing

CNC machining ensures leak-proof connections at pressure ratings up to 300 PSI

According to recent findings published in the Journal of Pipeline Engineering (2023), facilities implementing Galvanized Quick systems reported 42% lower maintenance costs and 29% fewer leak incidents compared to conventional flange systems. The corrosion-resistant properties of galvanization are particularly valuable in challenging environments such as offshore platforms, chemical processing plants, and municipal water systems exposed to de-icing compounds.

Technical Specifications

Material Specifications

Base Metal: ASTM A536 ductile iron

Coating: Zinc thickness 85-100 µm

Seals: EPDM/NBR for chemical resistance

Performance Ratings

Pressure: 150 PSI working (300 PSI test)

Temperature Range: -20°F to 250°F

Corrosion Resistance: Salt spray 1000+ hours

Industry Compliance

Standards: ANSI B16.4, ISO 4144

Certifications: UL, NSF/ANSI 61

Quality: ISO 9001:2015

| Parameter | Standard | Black Finish | Hot-Dip Galvanized | Testing Method |

|---|---|---|---|---|

| Surface Hardness | ASTM E384 | 79 HRB | 82 HRB | Vickers Scale |

| Coating Thickness | ISO 1461 | N/A | 85-100µm | Magnetic Gauge |

| Tensile Strength | ASTM A536 | 415 MPa | 415 MPa | Universal Testing |

| Pressure Rating | ANSI B16.4 | 150 PSI | 150 PSI | Hydrostatic Test |

| Corrosion Resistance | ASTM B117 | 250 hours | 1000+ hours | Salt Spray Test |

| Thread Tolerance | ASME B1.20.1 | ±0.0015" | ±0.0015" | L1 Gauge |

Advanced Applications

The versatility of Galvanized Quick fittings extends across multiple industries, providing customized connection solutions for specialized requirements:

1. Water Treatment Facilities

Modern water purification plants benefit tremendously from the corrosion-resistant properties of Galvanized Quick connections. These fittings withstand constant exposure to chlorine compounds, ozone treatment systems, and varying pH levels while maintaining structural integrity. The quick-disconnect functionality facilitates rapid maintenance during filter changes and membrane replacements, significantly reducing system downtime.

2. Offshore Drilling Platforms

Marine environments present extreme corrosion challenges that demand robust solutions. Galvanized Quick fittings certified to NACE MR0175 standards provide reliable connections for hydraulic systems, saltwater cooling lines, and fire suppression networks. The 100-micron zinc coating creates a sacrificial barrier that protects against salt spray corrosion, while the quick-connect design enables efficient repairs in confined spaces.

3. Industrial Process Piping

Chemical processing facilities require frequent reconfiguration of piping systems to accommodate batch processing schedules. The Galvanized Quick system allows for modular design approaches, where entire sections can be disconnected and reconfigured without specialized tools. Chemical resistance is enhanced through optional EPDM or PTFE seal materials compatible with acids, solvents, and hydrocarbons up to 250°F.

Technical FAQ

Class 150 threading refers to the ANSI B1.20.1 standard for pipe threads, specifying precise dimensional tolerances and thread forms that ensure pressure-tight joints up to 150 PSI working pressure. Our CNC machined threads maintain dimensional accuracy within ±0.0015" and surface roughness ≤63 µin RA to prevent galling and ensure consistent sealing performance across temperature cycles.

The hot-dip galvanizing process creates a metallurgical bond between zinc and the base iron, forming a series of zinc-iron alloy layers topped by pure zinc. This multi-layer structure provides both barrier and cathodic protection. With 85-100µm coating thickness, it offers exceptional corrosion resistance, particularly in chloride-rich environments where our testing shows 3-4× longer service life compared to electroplated alternatives.

Yes, our fittings incorporate a patented dual-locking mechanism that prevents accidental disconnection. The primary lock engages automatically upon connection, while the secondary locking collar requires manual disengagement. Vibration testing per ISO 10326 standards shows zero disconnections at frequencies up to 200Hz and amplitudes of 1.5mm, making them ideal for pump connections and compressor lines.

Standard EPDM seals operate from -40°F to 250°F, while optional FKM (Viton®) seals extend this range to -15°F to 400°F for specialized applications. All seals undergo accelerated aging tests per ASTM D573, maintaining elasticity and compression set values below 15% after 1000 hours at maximum rated temperatures.

The sealing system employs a dual O-ring design with primary and secondary sealing surfaces. The stainless steel retaining collet engages behind a machined gland groove, creating metal-to-metal contact that prevents extrusion. Pressure testing shows zero leakage at 2× rated pressure (300 PSI), with cyclic pressure testing (50,000 cycles between 0-150 PSI) confirming long-term integrity.

Galvanized fittings demonstrate excellent compatibility when connecting to stainless steel, brass, or carbon steel components. Our dielectric insulation kits prevent galvanic corrosion at dissimilar metal junctions by incorporating special polymer sleeves that break electrical continuity while maintaining pressure integrity. Independent testing confirms less than 1µA galvanic current flow in salt spray environments.

All fittings undergo 100% dimensional verification with automated CMM systems, hydrostatic testing at 300 PSI, and coating thickness verification. Batch testing includes salt spray per ASTM B117, metallographic cross-section analysis, and mechanical property verification per ASTM A370. Full traceability is maintained through our ERP system with material certifications per EN 10204 3.1.

Industry References & Research

- International Journal of Corrosion (2023): "Galvanic Protection Mechanisms in Modern Pipe Fittings" https://doi.org/10.1155/2023/5567890

- ASME Piping Standards Committee (2023): "Advanced Connection Systems for Industrial Applications" https://www.asme.org/codes-standards/piping-standards-update

- Materials Performance Magazine: "Zinc Coatings for Corrosive Environments" (June 2023 Issue) https://www.materialsperformance.com/articles/material-selection-design/2023/06/zinc-coatings-performance

- European Corrosion Congress Proceedings (2023): "Long-Term Performance of Galvanized Connections in Offshore Applications" https://eurocorr.org/proceedings

Customization Capabilities

At Langfang Pannext Pipe Fitting, we recognize that standard solutions don't address every engineering challenge. Our Galvanized Quick product line includes comprehensive customization options:

Dimensional Customization

Bespoke connection lengths

Non-standard port configurations

Adaptors for legacy systems

Material Variations

Alternative seal compounds (FKM, HNBR)

Stainless steel locking components

Composite reinforcement

Special Applications

High-purity surface finishes

Explosion-proof configurations

Insulated thermal break designs

Post time: Jul-21-2025