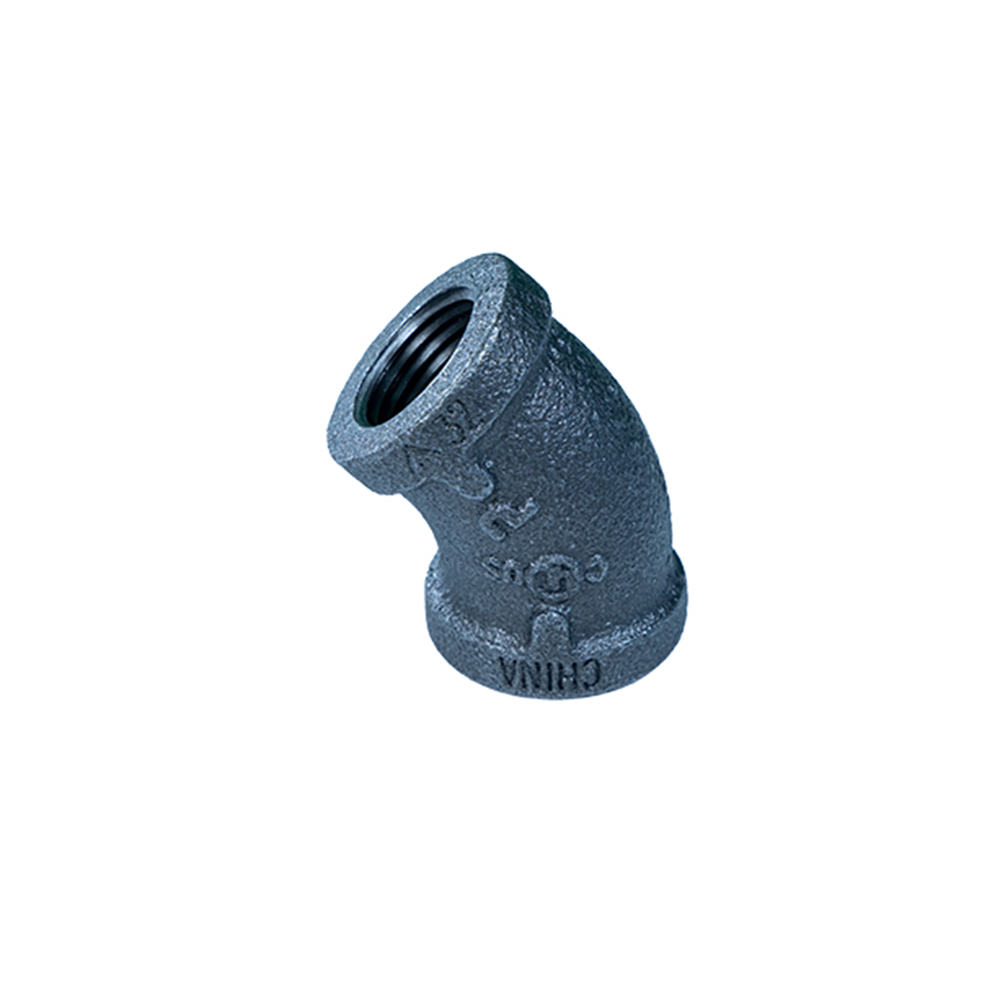

Key Terms: 2 inch 45 degree elbow, 2 inch street 45, 45 degree 3 inch elbow, 45 degree 4 inch elbow, 1 1 4 45 degree elbow

Industry Background & Market Trends: The Rising Demand for Precision Pipe Fittings

In recent years, driven by the modernization of fluid control systems, the global market for pipe fittings—especially the 2 inch 45 degree elbow—has shown steady annual growth of 5.2% (source: Global Fittings Market Outlook 2023). This upward trajectory is propelled by expanding infrastructure in petrochemical, metallurgy, and water supply sectors, alongside stricter environmental and safety standards. Products like the NPT 45 degree Straight Elbow offer unmatched efficiency, corrosion resistance, and longevity, directly supporting green manufacturing and intelligent pipeline construction.

Technical Specifications: Key Parameters & Comparative Analysis

Understanding the nuances between different elbow models (e.g., 2 inch 45 degree elbow, 2 inch street 45, 45 degree 3 inch elbow, 45 degree 4 inch elbow, and 1 1 4 45 degree elbow) is critical for system designers and maintenance engineers. The following table summarizes the most relevant parameters.

| Product | Nominal Size (inch) | Center-to-End (mm) | Wall Thickness (Sch 40/80) | Pressure Rating (psi) | Material Options | Surface Finish | Standard |

|---|---|---|---|---|---|---|---|

| 2 inch 45 degree elbow | 2" | 51 | 3.91 / 5.54 | 150-3000 | Stainless, Carbon, Alloy Steel, Brass | Sandblast, Paint, Zinc-plated | ANSI/ASME B16.9 |

| 2 inch street 45 | 2" | 52 | 3.91 / 5.54 | 150-2000 | Stainless, Mal. Iron | Powder Coat | ASTM A234 |

| 45 degree 3 inch elbow | 3" | 64 | 5.49 / 7.62 | 150-3000 | Carbon Steel | Black, Galvanized | ANSI/ASME B16.9 |

| 45 degree 4 inch elbow | 4" | 76 | 6.02 / 8.56 | 150-2000 | Stainless, Cast Iron | Epoxy, Galvanized | ANSI/ASME B16.9 |

| 1 1 4 45 degree elbow | 1 1/4" | 44 | 3.56 / 4.85 | 150-2000 | Stainless, Brass | Natural, Chrome | DIN 2605 |

Manufacturing Process Flow: How Are 2 inch 45 degree elbows Made?

- Raw Material Preparation – Selection of superior grades of stainless steel, carbon steel, or alloy per ISO 9001.

- Cutting & Forming – Pipes are cut to approximate length before being hot-forged or cast into a 45° angle using precision dies.

- Heat Treatment – To stabilize structure and enhance mechanical properties (ASTM A234/A403 compliance).

- CNC Machining – Key dimensions like threads and faces are finished to tight tolerances (±0.1mm), using advanced CNC technology.

- Surface Treatment – Sandblasting, electro-galvanizing, or epoxy paint for corrosion resistance.

- Nondestructive Testing – Hydrostatic (up to 3,000psi) and radiographic tests, as per ASME B16.9 and ISO 5208, certify pressure performance.

- Final Inspection & Packing – Each 2 inch 45 degree elbow is stamped, checked for marking accuracy, and securely packaged per client’s requirements.

Compliance, Testing & Longevity: What Sets the NPT 45 Degree Straight Elbow Apart?

NPT 45 degree Straight Elbow components are manufactured in strict adherence to both ISO 9001:2015 and ANSI/ASME B16.9 standards. Full material traceability (from mill to shipment), rigorous ultrasonic and visual inspection, and state-of-the-art CNC finishing ensure that every elbow offers flawless leak sealing—critical in safety-relevant sectors like oil & gas, refinery, LNG terminals, and high-pressure water distribution.

- Material grades ex-stock: ASTM A105/A234 WPB (carbon steel), ASTM A182 F304/316 (stainless steel), plus NPT threaded, socket weld or butt-weld end options.

- Hydrostatic test: Burst pressure up to 3x the rated working pressure for each 2 inch 45 degree elbow batch, per API 598 / ISO 5208.

- Typical tested service life exceeds 30 years for stainless steel versions; see industry's top quartile standards in the chart above.

- Coating options: Epoxy (for desalination), zinc-plated (waterworks), powder coat (construction) – all proven to reduce maintenance costs over lifetime.

Application Scenarios: Where Does the 2 inch 45 degree elbow Excel?

- Petrochemical Piping: High-pressure transfer lines — resistant to H2S, brine, and hydrocarbon media.

- Urban Water Supply/Drainage: Flow redirection in municipal water systems and wastewater plants; certified for potable water (NSF/ANSI 61).

- Metallurgical Industry: Process cooling and gas handling with heavy-duty wall thickness (sch 80/XXS).

- Marine/Offshore: Stainless versions resist seawater pitting; favored for shipboard systems.

- Fire Protection Systems: UL/FM approved elbows for sprinkler branch lines.

- General Industrial: HVAC, compressed air lines, pharmaceutical process plants.

Customer Feedback: “The 2 inch 45 degree elbow from PANNEXT delivered seamless installation, withstood surge tests up to 250% of rated pressure, and dramatically reduced our on-site welding time.” — Project Superintendent, Middle East Oil Terminal (2023)

Supplier Benchmark: PANNEXT vs. Other Major Manufacturers

| Manufacturer | Material Range | Certification | Max Pressure (psi) | Tolerance | MOQ (pieces) | Delivery (weeks) | Warranty |

|---|---|---|---|---|---|---|---|

| PANNEXT | Stainless, Carbon, Brass, Alloy | ISO, ANSI, PED, DNV | 3000 | ±0.1 mm | 10 | 2-4 | 5 Years |

| Ward Mfg (US) | Carbon, Stainless | UL, FM, ISO | 2000 | ±0.3 mm | 20 | 5-7 | 2 Years |

| Viega (Germany) | Stainless, Brass | ISO, EN | 1500 | ±0.2 mm | 50 | 8-12 | 3 Years |

| Mueller Ind. (US) | Brass, Ductile Iron | NSF, ANSI | 1600 | ±0.25 mm | 30 | 6-10 | 1 Year |

Customization & Engineering Support

- Custom Alloys/Coatings: Nickel, PTFE, glass lining for corrosive service;

- Special Angles/Ends: Street 45°, hybrid end configurations (NPT x Butt-Weld, Socket x Thread), and odd sizes (e.g. 1 1/4", 1 1/2" elbows);

- Design for High-Flow: CFD-based optimization for lower head loss in HVAC and process systems.

- Batch Testing: Client-specified test documentation, chemical analyses, paired with 3.1 material certificates.

- On-site Technical Services: Welding, alignment, and integrity support for pipeline contractors.

Case Studies: Real-World Deployments

Over 2,000 pieces of 2 inch 45 degree elbow installed in high-velocity potable water mains delivered zero-leak service under 24/7 operation for over 2 years with routine quality checks.

The advanced anti-corrosive coating on PANNEXT elbows extended cleaning intervals by 40%, outperforming cast iron alternatives (data verified by third-party SGS inspection).

45 degree 3 inch elbow and 45 degree 4 inch elbow units certified to UL/FM used in NFPA-compliant sprinkler systems: confirmed by consultant flow tests to provide minimal headloss in tightly spaced installations.

Frequently Asked Questions (FAQ): Technical Knowledge Deep Dive

- 1. What are the main material options for 2 inch 45 degree elbow fittings?

- Typical materials include ASTM A234 WPB carbon steel, A182 F304/F316 stainless steel, and brass for potable or non-corrosive applications. All materials conform to ISO/ANSI standards.

- 2. What standards govern manufacturing and installation?

- ANSI/ASME B16.9 for dimensions; ASTM A234/A403 for materials; NPT threads per ASME B1.20.1. Installation often follows ASME PCC-2 (pipeline components).

- 3. How is pressure rating defined and tested?

- Pressure rating is based on wall thickness/schedule (e.g., Sch 40 vs. Sch 80) and tested hydrostatically as per API 598, generally at 1.5 to 3x design pressure.

- 4. What is a “street 45” elbow?

- It is a 45° elbow with one male and one female end, allowing direct connection to female-threaded fittings/pipes without a coupling, ideal for space-saving installations.

- 5. What is the difference between socket weld and butt weld elbows?

- Socket weld elbows have ends designed for pipe to be inserted and then fillet welded; butt weld elbows involve pipe end-to-end welding for a smooth-flow finish in process loops.

- 6. What surface finishing options are available?

- Treatments include sandblast, zinc/epoxy coating, powder painting, and passivation (for stainless). Choice depends on environment: marine, underground, or sanitary applications.

- 7. What is the typical delivery cycle and how can clients track orders?

- Standard sizes (e.g., 2 inch 45 degree elbow) ship within 2-4 weeks. All orders receive batch tracking with heat number traceability (MRP/ERP integration). Custom projects may take 4-8 weeks depending on quantity and complexity.

Order Fulfillment, QA & After-Sales Support

Warranty: Five-year leakage/performance warranty per PANNEXT Policy.

Support: 24/7 technical hotline, dedicated engineer for major projects, comprehensive documentation (MTRs, test certificates).

Returns/Claims: Streamlined return process for non-conforming goods. All elbows laser-marked for lifetime traceability and QA audits.

- ASME B16.9: Factory-Made Wrought Steel Buttwelding Fittings: ASME Official Site

- Pipe Fittings Industry Analysis 2023: FittingForum.com

- Pressure Test Standards FAQ: Engineering Tips Forum

- Metallurgy in Elbow Fittings: ScienceDirect

Post time: Aug-01-2025