Official Website: https://www.pannextfittings.com

Tel: 0316-2652671 | Email: fanda@pannext-casting.com

Mobile: 0086-15690252169

Address: 236 West Guangming Road, Langfang, Hebei, China

Introduction: The Advancement of Malleable Iron Pipe Systems

In the global industrial landscape, malleable iron and its derivatives – including malleable iron unions, malleable pipe fittings, malleable steel, and black cast iron fittings – play fundamental roles in plumbing, HVAC, fire protection, gas distribution, and industrial processing systems. As technology marches forward, the versatility, mechanical properties, and diverse applications of malleable iron make it a preferred choice for safety, resilience, and cost efficiency.

Langfang Pannext Pipe Fitting Co., Ltd. stands at the forefront of innovation in malleable iron products, committed to quality manufacturing, technical advancement, and global reach. With an emphasis on professional engineering and compliance with leading standards, Pannext delivers products noted for robustness, longevity, and ease of installation.

What is Malleable Iron? Material Characteristics & Industry Advantages

Malleable iron is a type of cast iron that has undergone heat treatment to increase its ductility while retaining much of the strength and corrosion resistance typical of cast iron. Key advantages include:

- Outstanding ductility and impact resistance compared to standard grey cast iron

- Excels in threaded connections due to minimal brittleness

- Resilience under cyclic thermal and pressure stress – required for malleable iron unions and malleable pipe fittings

- Intrinsic corrosion resistance and compatibility with a diverse array of fluids

- Enhanced machinability and adaptability for complex fitting geometries

Technical Parameters of Malleable Iron & Industry Standards

The performance of malleable iron components is determined by mechanical, chemical, and dimensional parameters governed by international standards (ASTM A197, BS EN 1562, ISO 5922, etc.). Below, we summarize essential technical parameters found in current industry adoption:

| Parameter | Value / Range | Standard | Industry Reference |

|---|---|---|---|

| Tensile Strength | ~350-450 MPa | ASTM A197 / ISO 5922 | ASTM |

| Yield Strength | ~240-310 MPa | EN 1562 | EN 1562 |

| Elongation | ~10-15% | ASTM A197 | Total Materia |

| Hardness (Brinell) | ~130-180 HB | ISO 5922 | Matmatch |

| Max Operating Pressure | 25 bar (363 psi) | System Dependent | Piping-Designer |

| Operating Temp Range | -20°C to +300°C | Application Dependent | Engineering Toolbox |

| Thread Standard | BSP / NPT | ISO 7-1, ASME B1.20.1 | Wikipedia |

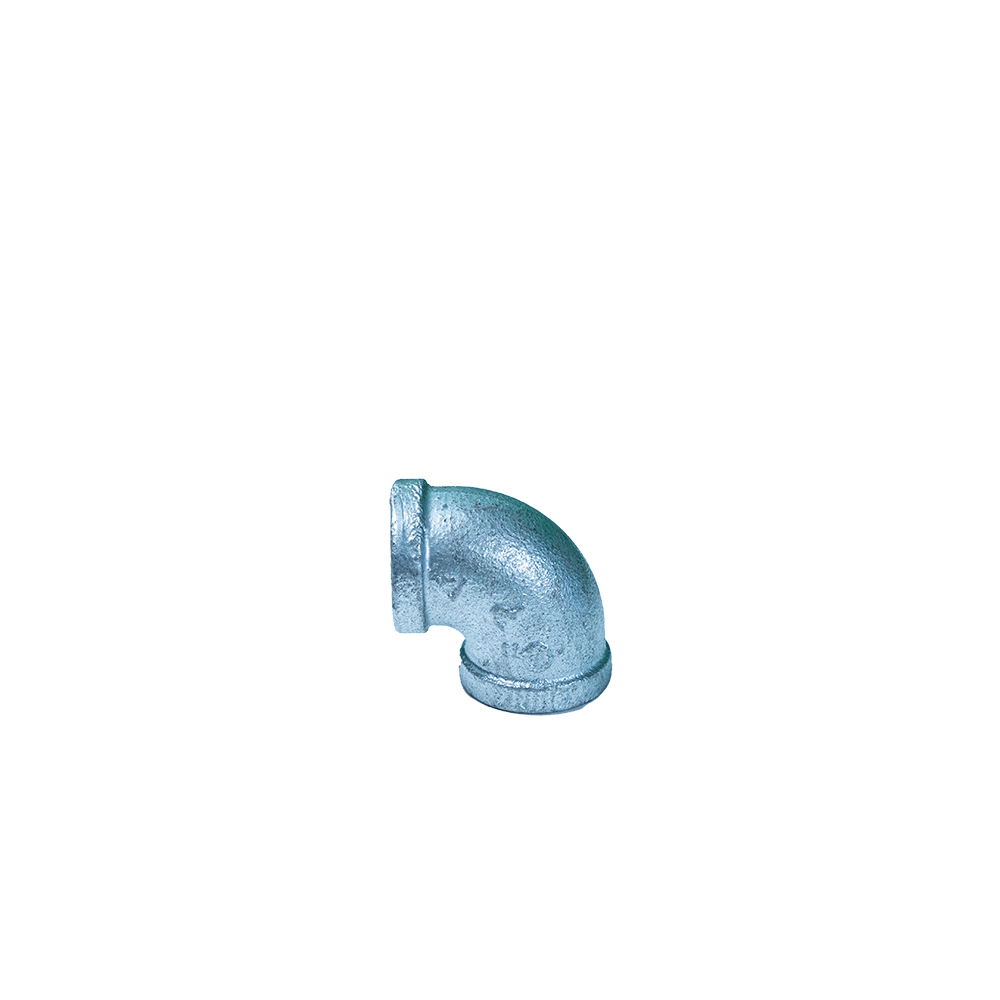

Product Highlight: Hot Sale Product 90 Degree Elbow

The 90° elbow is designed to connect two pipes via male and female threading, enabling a precise 90-degree redirection of fluid flow in pipelines. It is widely used in plumbing, heating, and industrial systems to change direction at right angles, boosting installation flexibility and space efficiency.

Core attributes:

- Available in galvanised or black finish (black cast iron fittings)

- Engineered from top-grade malleable iron or malleable steel

- Meets ISO, EN, and ASTM threading standards for both BSP and NPT

- Tested for >25 bar working pressure and >440 MPa tensile strength

- Corrosion-resistant surfaces for harsh environments

- Multiple sizes and variations for industry adaptability

Learn more/specs: Hot Sale 90 Degree Elbow Product Page

Applications of Malleable Iron Unions & Fittings

Malleable iron unions, elbows, tees, and couplings are core components in:

- Fire protection systems: Reliable, pressure-resistant distribution in sprinkler piping

- Plumbing networks: Domestic, commercial, and municipal water supply

- HVAC and heating frameworks: Adapting to frequent thermal cycles and pressurization

- Oil, gas, and chemical transport: For safe connection in potentially corrosive or high-pressure environments

- Compressed air lines: Robust, leak-proof joints with precise threading

- Industrial processing: Connecting reactor, fermenter, and utility lines

- Infrastructure retrofitting: Flexible integration with modern and legacy piping standards

Comparative Overview: Malleable Pipe Fittings vs. Alternative Materials

When compared with PVC, ductile iron, stainless steel, and brass, malleable pipe fittings deliver superior performance in threaded connection integrity, impact resistance, high/low temperature tolerance, and cost-effectiveness for large-scale installations. They remain the de facto choice for threaded steel and iron pipelines according to international forums like Eng-Tips Pipe Threads Forum.

Expert FAQ: Industry Terms, Standards, and Professional Advice

- 1. What material is typically used for malleable iron unions and elbows?

- Malleable iron following ASTM A197, EN 1562, generally containing 2–3% carbon and 1–2% silicon, heat treated for enhanced ductility and impact strength. Sometimes, malleable steel is also considered for higher-strength applications.

- 2. What thread standards are applied to malleable pipe fittings?

- Primary standards are BSP (ISO 7-1) and NPT (ASME B1.20.1). Correct selection ensures compatibility and pressure tightness.

- 3. What are the main sizes and pressure specifications for the 90 Degree Elbow?

- Standard sizes: ⅛" (DN6) to 4" (DN100), pressure rating: up to 25 bar (363 psi). Ensure compliance with pipeline system design.

- 4. How is malleable iron different from ductile iron?

- Malleable iron is cast and heat treated to create a ferritic/pearlitic microstructure, while ductile iron contains nodular graphite, offering higher ductility for larger sections but with differing threading and impact characteristics.

- 5. What are typical installation standards for black cast iron fittings and galvanized versions?

- Installation must comply with EN 10242 (Europe), ANSI/ASME B16.3 (US), and local code for joint tightening torque, sealant, and corrosion protection (paint or zinc coating for galvanized fittings).

- 6. What corrosion protection methods are used for malleable iron unions?

- Hot-dip galvanizing (HDG), painting, or powder coating are common. Black cast iron fittings are suitable for indoor, non-corrosive environments, while HDG is recommended for aggressive or outdoor settings.

- 7. Are malleable pipe fittings suitable for high-temperature or gas/fire applications?

- Yes. Certified malleable fittings withstand continuous use up to 300°C and are extensively utilized in fire suppression and gas distribution due to reliable sealing and robust mechanical properties.

Industry Authority & Scientific References

To ensure ongoing compliance and technical superiority of malleable iron components, Langfang Pannext Pipe Fitting Co., Ltd. rigorously follows international material and design standards. For further reading, industry leaders reference resources such as:

Post time: Jul-25-2025