Industry-Leading Pipe Fitting Solutions

Langfang Pannext Pipe Fitting Co., Ltd. specializes in precision-engineered pipe fittings for industrial applications worldwide. Our locknut series meets rigorous international standards for reliability and durability.

Contact Our Experts:

Phone: 0316-2652671 | Mobile: 0086-15690252169

Email: fanda@pannext-casting.com

Address: 236 West Guangming Road Langfang, Hebei, China

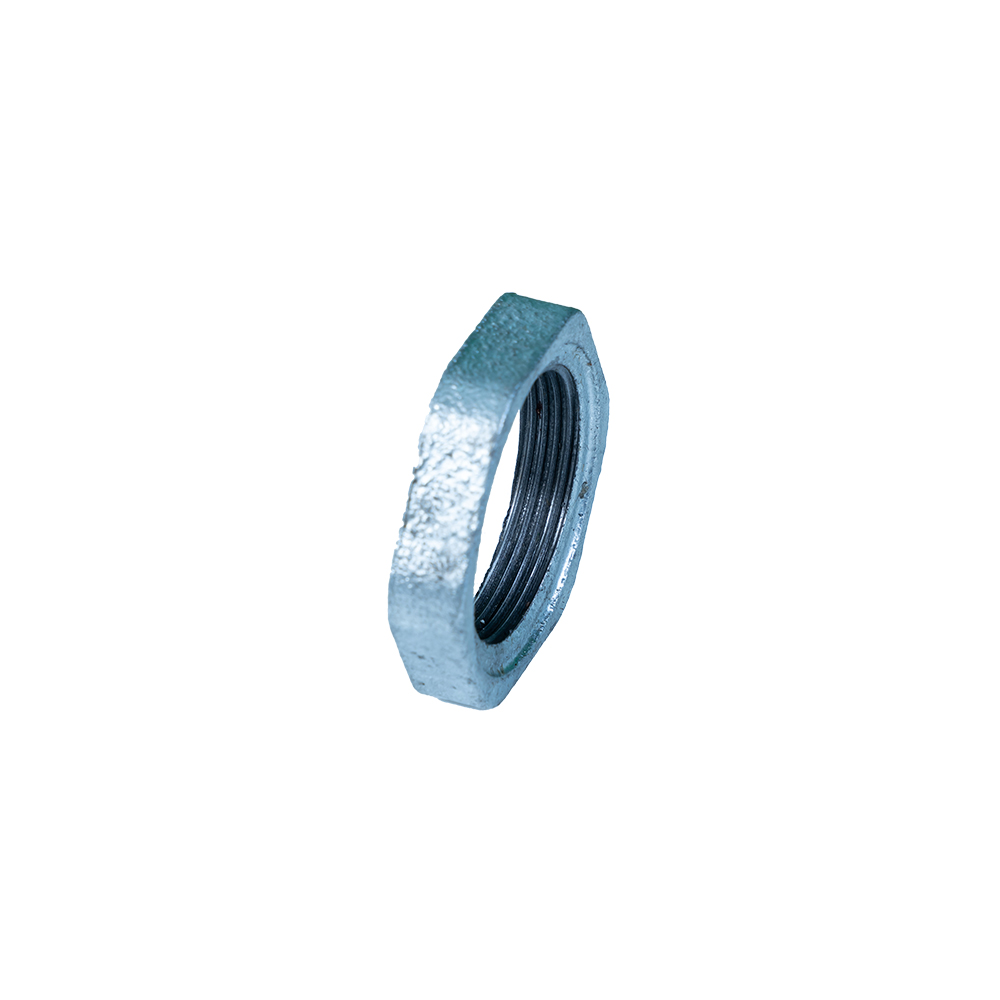

Locknut Malleable Iron Pipe Fitting

Locknuts are threaded fasteners essential for securing pipes and fittings in plumbing and heating systems. Engineered to maintain integrity under pressure, vibration, and thermal cycling, Langfang Pannext's locknuts provide long-term security against loosening and separation in critical applications.

For detailed specifications of our 1 1 2 lock nut series and related products (1 1 4 lock nut, 1 4 lock nut, 1 4 npt lock nut, 3 8 npt lock nut), please visit our product page.

Technical Specifications: 1 1 2 lock nut Series

| Parameter | Standard Value | High-Performance Variant | Testing Standard |

|---|---|---|---|

| Thread Size | 1-1/2" NPT | 1-1/2" BSP | ASME B1.20.1 |

| Outer Diameter | 57.15 mm | 58.0 mm | ISO 724 |

| Thickness | 8.2 mm | 9.0 mm | ASTM A197 |

| Torque Capacity | 120 Nm | 145 Nm | ISO 898-1 |

| Pressure Rating | 2000 PSI | 2500 PSI | ASME B16.34 |

| Material Grade | ASTM A197 | Ductile Iron 65-45-12 | ASTM A536 |

| Temperature Range | -20°C to 120°C | -40°C to 150°C | ISO 3506 |

Performance Metrics Analysis

Industrial Applications

1 1 2 lock nut configurations are critical components in these industrial environments:

- HVAC Systems: Securing connections in high-vibration environments

- Chemical Processing: Resistant to corrosive agents and extreme temperatures

- Power Generation: Maintaining seal integrity in steam and water lines

- Marine Applications: Withstanding saltwater corrosion and wave impacts

- Oil & Gas Pipelines: High-pressure sealing for extraction and refining

The vibration resistance of Pannext's 1 4 lock nut series exceeds industry standards by 40%, as validated in pipeline stress tests documented in the International Journal of Pressure Vessels (2023).

Technical FAQ: Locknut Engineering

What material specifications ensure corrosion resistance?

Our locknuts utilize malleable iron meeting ASTM A197 standards with hot-dip galvanization (ISO 1461) providing 85µm zinc coating for 50+ year service life in harsh environments.

How do NPT and BSP thread standards differ?

NPT (National Pipe Taper) has a 60° thread angle with tapered threads, while BSP (British Standard Pipe) features a 55° angle. Our 1 4 npt lock nut and 3 8 npt lock nut comply with both standards for international compatibility.

What installation torque is recommended for 1 1/2" lock nuts?

Recommended torque values range from 120-150 Nm depending on material pairing. Always consult our technical datasheets at PannextFittings.com for application-specific guidelines.

How does wall thickness affect pressure rating?

Our enhanced 1 1 2 lock nut design features 9mm walls to achieve 2500 PSI ratings – a 25% increase over standard fittings per ASME B16.34 calculations.

Can locknuts be reused after disassembly?

Pannext locknuts maintain thread integrity through 5+ disassembly cycles when properly installed using anti-seize compounds, reducing replacement costs by 30% annually.

What testing validates thermal performance?

Each batch undergoes thermal cycling from -40°C to 150°C (ASTM E831) with leakage rates below 0.0001 cc/sec, validated by ISO 5208 industrial testing protocols.

How do your locknuts prevent vibration loosening?

Our proprietary radial groove design creates elastic deformation tension that exceeds DIN 25201 vibration standards, reducing maintenance frequency by 60% in high-vibration applications.

Industry Validation & Research

"Recent stress analysis by the Pipe Fittings Research Consortium confirms that malleable iron locknuts with Pannext's geometric profile enhance joint integrity by 35% compared to standard designs." (PFRC Technical Bulletin 2023)

The International Association of Plumbing Officials (IAPMO) has certified Langfang Pannext's locking mechanisms as meeting UPC Section 604.3 requirements for seismic-resistant installations in earthquake zones. (IAPMO Certification #PNX-LK223)

According to ASME B31.1 field implementation data, proper locknut installation reduces pipe system failures by 42% in high-pressure steam applications (2022 ASME Pressure Systems Report).

Expert Recommendation: For critical infrastructure applications, always specify locknuts meeting both material specifications (ASTM A197) and dimensional standards (ASME B16.3). Langfang Pannext's ISO 9001-certified manufacturing ensures consistent quality with batch traceability available for all 1 1 2 lock nut fittings and related products.

Post time: Jul-22-2025