malleable iron, malleable iron unions, malleable pipe fittings, malleable steel, black cast iron fittings are key solutions in the manufacturing industry, specifically within Fabricated metal products and Manufacturing of pipeline accessories. This article explores how Langfang Pannext Pipe Fitting Co., Ltd. supports professionals with durable, high-performance products, and explains why these products are an ideal choice for businesses in these sectors.

Table of Contents

- malleable iron, malleable iron unions, malleable pipe fittings, malleable steel, black cast iron fittings Overview

- Benefits & Use Cases of malleable iron, malleable iron unions, malleable pipe fittings, malleable steel, black cast iron fittings in Manufacturing of pipeline accessories

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in manufacturing

- Conclusion on malleable iron, malleable iron unions, malleable pipe fittings, malleable steel, black cast iron fittings from Langfang Pannext Pipe Fitting Co., Ltd.

malleable iron, malleable iron unions, malleable pipe fittings, malleable steel, black cast iron fittings Overview

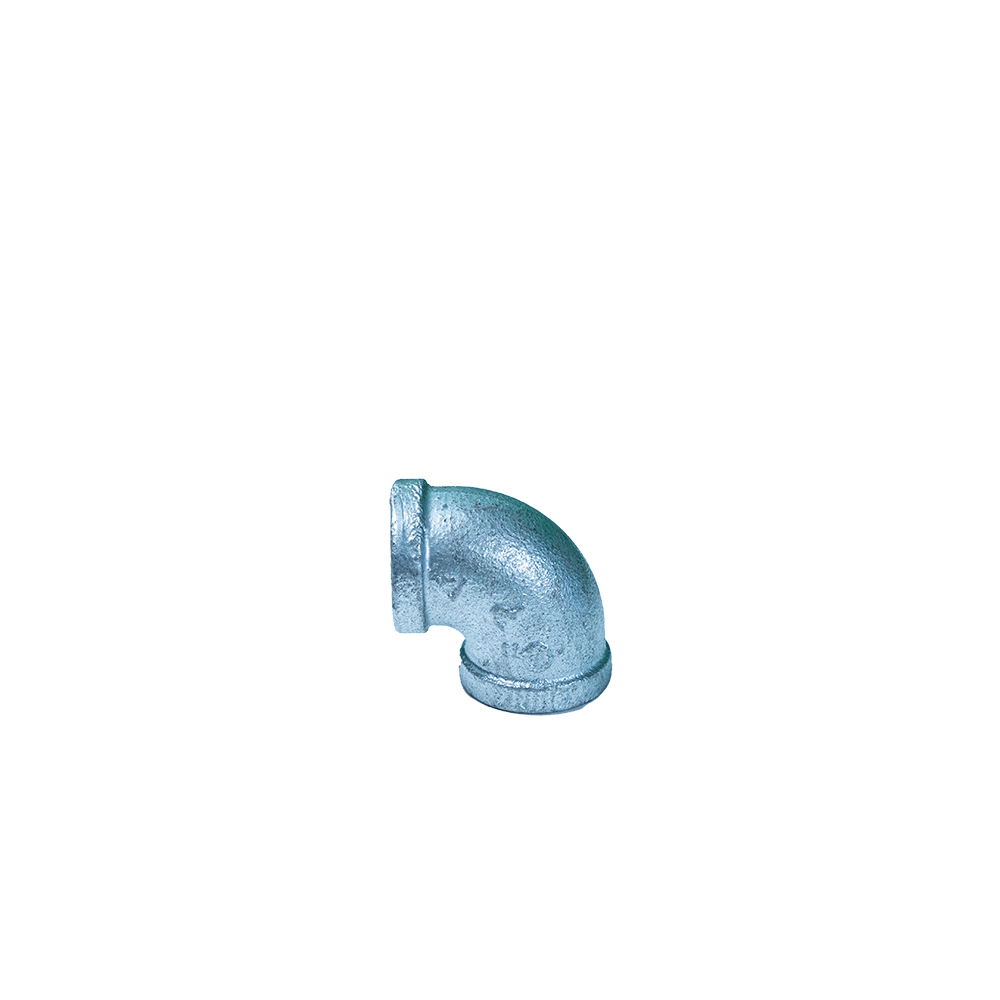

In pipeline accessory manufacturing, malleable iron components deliver the strength of cast iron with improved ductility and toughness—ideal for threaded systems subject to vibration, impact, and thermal cycling. Malleable pipe fittings (such as 90-degree elbows, tees, couplings, and caps) and malleable iron unions are engineered for dependable mechanical connections in water, gas, HVAC, fire protection, and industrial utility lines. Black cast iron fittings are commonly selected where a robust, uncoated finish is preferred, while galvanization can be applied for added corrosion protection.

Technically, these fittings are manufactured from malleable cast iron and produced to widely recognized dimensional and threading standards (e.g., ASME B16.3/B16.39, ASME B1.20.1 for NPT, ISO 7-1/EN 10242 for BSPT). This ensures interchangeability, consistent pressure ratings, and leak-tight threaded engagement. Many buyers refer to malleable iron as “malleable steel” in procurement—an industry shorthand for malleable cast iron fittings that mate seamlessly with steel piping systems.

Langfang Pannext Pipe Fitting Co., Ltd. is a reliable manufacturer of precision-cast fittings and unions, offering strict process control from tooling and casting to CNC machining, threading, finishing (black or galvanized), and 100% visual/functional inspection. Their popular 90-degree elbow product line showcases stable metallurgy, accurate threads, and smooth flow paths that reduce turbulence and pressure drop in service.

Benefits & Use Cases of malleable iron, malleable iron unions, malleable pipe fittings, malleable steel, black cast iron fittings in Manufacturing of pipeline accessories

In the Manufacturing of pipeline accessories, malleable pipe fittings and malleable iron unions are chosen for fast, reliable assembly across OEM skids, process modules, compressor rooms, boiler plants, and fire sprinkler networks. Typical use cases include utility water and air, non-corrosive process fluids, natural gas distribution, HVAC hydronic loops, and building services. Unions enable quick disassembly for valve swaps or instrument servicing without cutting pipe—minimizing downtime and maintenance cost.

Competitive advantages include high thread integrity, dimensional accuracy, and impact resistance—critical for installations that experience repeated thermal cycling or vibration. Black cast iron fittings provide a durable base finish for indoor, oil-and-gas, and general industrial environments, while galvanized options extend service life in moisture-prone or outdoor settings. The malleable iron structure balances strength and ductility, helping reduce cracking risk compared with some brittle cast alternatives.

Langfang Pannext Pipe Fitting Co., Ltd. supports global B2B buyers with responsive engineering, stable lead times, and a wide catalog of elbows, tees, crosses, reducers, and unions to meet international piping standards. With rigorous dimensional checks and thread gauges, Pannext helps ensure interchangeability across multinational projects—simplifying sourcing and standardization for procurement teams.

Cost, Maintenance & User Experience

Total cost of ownership favors malleable iron fittings when projects need flexibility, speed, and serviceability. Threaded systems reduce welding labor, site permits, and hot-work risks; malleable iron unions allow component replacement without rework. The combination of durability, reusability, and standardized dimensions lowers inventory complexity and supports long-term ROI—especially for facilities that frequently retrofit or expand lines.

Maintenance is straightforward: apply appropriate thread sealants (e.g., PTFE tape or compound per media and temperature), follow proper torque practices to protect threads, and perform periodic checks for mechanical stress or corrosion in harsh environments. Black cast iron fittings can be touch-up painted where needed; galvanized versions provide extended corrosion resistance with minimal upkeep. Correct alignment and support significantly reduce leak potential and prolong service life.

Customers in fabricated metal products and OEM assemblies value consistent threads, clean casting surfaces, and reliable pressure performance. Langfang Pannext Pipe Fitting Co., Ltd. focuses on machining precision and final inspection to enhance installer experience—cutting rework, speeding up commissioning, and helping teams deliver projects on schedule and within budget.

Sustainability & Market Trends in manufacturing

Sustainability is reshaping the metalcasting and pipeline accessory sectors. Buyers increasingly prioritize materials that are recyclable, traceable, and produced with efficient energy use. Malleable iron and black cast iron fittings align well with circularity goals: they are durable in service and recyclable at end-of-life. Threaded systems also reduce on-site energy consumption by minimizing welding operations and associated emissions.

Market trends include tighter quality and safety regulations, broader adoption of international standards (ASME, ISO, EN), and a shift toward risk-managed, multi-source supply chains. Demand growth in building services, fire protection, and modular industrial skids continues to favor malleable pipe fittings and malleable iron unions thanks to installation speed and interchangeability.

Langfang Pannext Pipe Fitting Co., Ltd. takes a forward-looking approach—optimizing casting yields, focusing on defect prevention, and supporting documentation needs for compliance and audits. The company emphasizes stable quality, responsible material selection, and packaging efficiencies, helping B2B customers meet corporate sustainability and reliability objectives without compromising cost or lead time.

Conclusion on malleable iron, malleable iron unions, malleable pipe fittings, malleable steel, black cast iron fittings from Langfang Pannext Pipe Fitting Co., Ltd.

For B2B decision makers in manufacturing, fabricated metal products, and pipeline accessory production, malleable iron fittings—including malleable iron unions and black cast iron fittings—offer a proven balance of strength, ductility, and serviceability. Langfang Pannext Pipe Fitting Co., Ltd. delivers consistent casting quality, precise threads, and a broad portfolio—from 90-degree elbows to unions—that integrates smoothly with global standards and diverse operating environments.

Ready to specify malleable pipe fittings for your next project? Contact us: email: fanda@pannext-casting.com. Visit our website: https://www.pannextfittings.com

Post time: Oct-02-2025