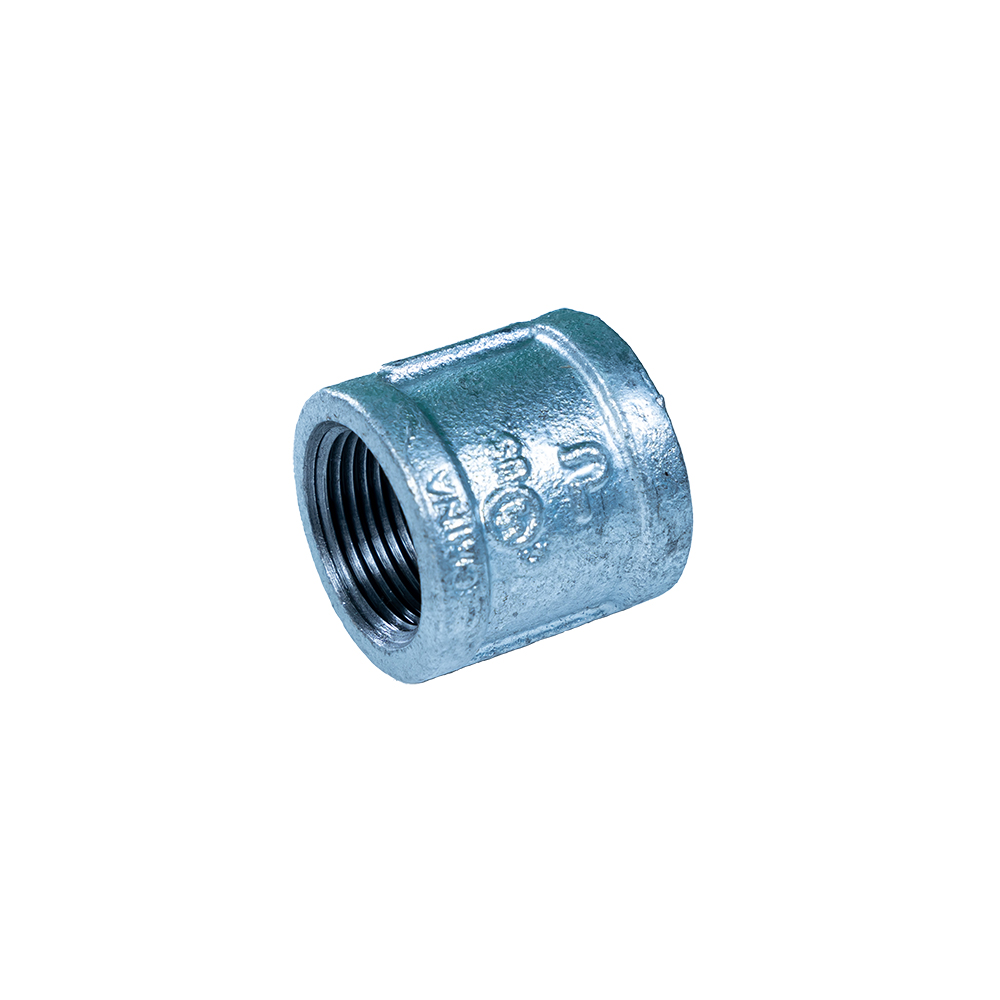

Practical Guide to Socket NPT Couplings for a 3/8-inch Line

If you’re speccing a 3 8 npt fitting for a maintenance job or a new manifold, here’s the short answer: the humble socket NPT coupling still rules in North American pipe work. PANNEXT’s Black or Galvanized Socket NPT COUPLINGS, cast in Hebei and finished to tight thread standards, are the kind of bread‑and‑butter hardware crews actually trust. I’ve seen countless sites swap fancy quick-connects back to NPT after leaks under vibration. Happens more than vendors admit.

Product snapshot

Name: Black or Galvanized Socket NPT COUPLINGS. Origin: 236 West Guangming Road, Langfang, Hebei, China. The coupling is a female‑threaded connector for joining two pipes—simple, reliable, and widely used across construction, utilities, and light industry. For a 3 8 npt fitting, you’re typically choosing this when you want a compact, all‑metal, thread-sealed joint with proven lineage.

| Parameter | Spec (≈ / typical) |

|---|---|

| Size range | 1/8"–4"; focus: 3 8 npt fitting (3/8" NPT female x female) |

| Material | Malleable cast iron (ASTM A197/A197M) or comparable |

| Finish | Black (as-cast/painted) or Hot‑dip galvanized (ASTM A153/A153M) |

| Threads | NPT, ASME B1.20.1; 60° tapered pipe thread |

| Pressure rating | Up to ≈300 psi for water/oil/air at 100°F (Class 150 style); real-world use may vary |

| Temperature | -20°C to 200°C typical, depending on sealant and media |

| Certs | Factory ISO 9001; material and coating certs available on request |

How they’re made (quick process flow)

- Materials: malleable iron casting, then annealed for toughness; hot‑dip zinc for galvanized units.

- Methods: sand casting → heat treatment → CNC machining → thread cutting to ASME B1.20.1 → deburr.

- Testing: thread plug/gauge inspection; hydrostatic test ≈1.5× working pressure; coating thickness check; salt‑spray (ASTM B117) sampling.

- Service life: ≈15–25 years in mild environments; shorter in brine/chemical atmospheres unless galvanized.

- Industries: construction MEP, HVAC, waterworks, compressed air, light oil & gas utility, agriculture.

Where a 3 8 npt fitting shines

Meter runs, small compressors, dosing pumps, condensate lines, and test ports. I’ve seen maintenance teams keep a bag of 3/8" couplings for “Friday 4 p.m.” fixes—because they just work. Thread sealant (PTFE tape or anaerobic) and proper torque do the heavy lifting.

Market trend, briefly

Despite push‑fit hype, NPT remains dominant in brownfield retrofits and cost-sensitive builds. The quiet trend is better QC—tighter threads and thicker zinc—to cut call-backs. Procurement folks tell me they now insist on traceable heat numbers and gauging logs.

| Vendor | Standards & QC | Galvanizing | Lead time | Notes |

|---|---|---|---|---|

| PANNEXT (Hebei) | ISO 9001; threads per ASME B1.20.1; batch hydrotest | ASTM A153/A153M cited | Around 2–4 weeks typical | Consistent casting; competitive on volume |

| Generic Importer A | Varies; limited gauge logs | Electro‑zinc on some SKUs | Stock‑dependent | Lower cost; check threads carefully |

| Local Fabricator B | Good traceability; small batches | Hot‑dip by partner shop | Fast for small runs | Higher unit price; flexible specs |

Customization and real-world notes

- Thread options: NPT standard; BSPT on request (check project spec).

- Coatings: black, hot‑dip galvanized; food‑grade epoxy topcoat optionally.

- Marking: heat number, size, and logo for traceability.

- Packaging: moisture‑barrier bags help in coastal warehouses.

Field feedback and mini case

“Threads grab cleanly—no cross‑start,” a Midwest HVAC foreman told me after swapping to galvanized PANNEXT couplings on compressor drops. Another case: a water treatment skid OEM reported zero rework after the supplier moved to stricter thread gauging and 96‑hour salt-spray verification (sampled).

Quality, testing, compliance

Look for ASME B1.20.1 thread conformance, ASTM A197 material compliance, and ASTM A153 galvanizing thickness (when applicable). Hydro tests at ≈1.5× working pressure for 60 s with no visible leakage are a good baseline. For corrosion risk, request ASTM B117 data. It sounds dry, I know, but it prevents call-backs.

Bottom line for a 3 8 npt fitting

Keep it simple: choose malleable iron, verified NPT threads, and hot‑dip galvanizing if there’s moisture. Confirm pressure class against your media and temperature, then document the test and coating certs. That’s how you avoid “Friday 4 p.m.” surprises.

- ASME B1.20.1, Pipe Threads, General Purpose (Inch)

- ASTM A197/A197M, Standard Specification for Cupola Malleable Iron

- ASTM A153/A153M, Standard Specification for Zinc Coating (Hot-Dip) on Iron and Steel Hardware

- ASTM B117, Standard Practice for Operating Salt Spray (Fog) Apparatus

- ISO 9001, Quality management systems—Requirements

Post time: Sep-30-2025