Half Threaded Socket or Coupling (UL Certificate): Field Notes, Specs, and Real-World Use

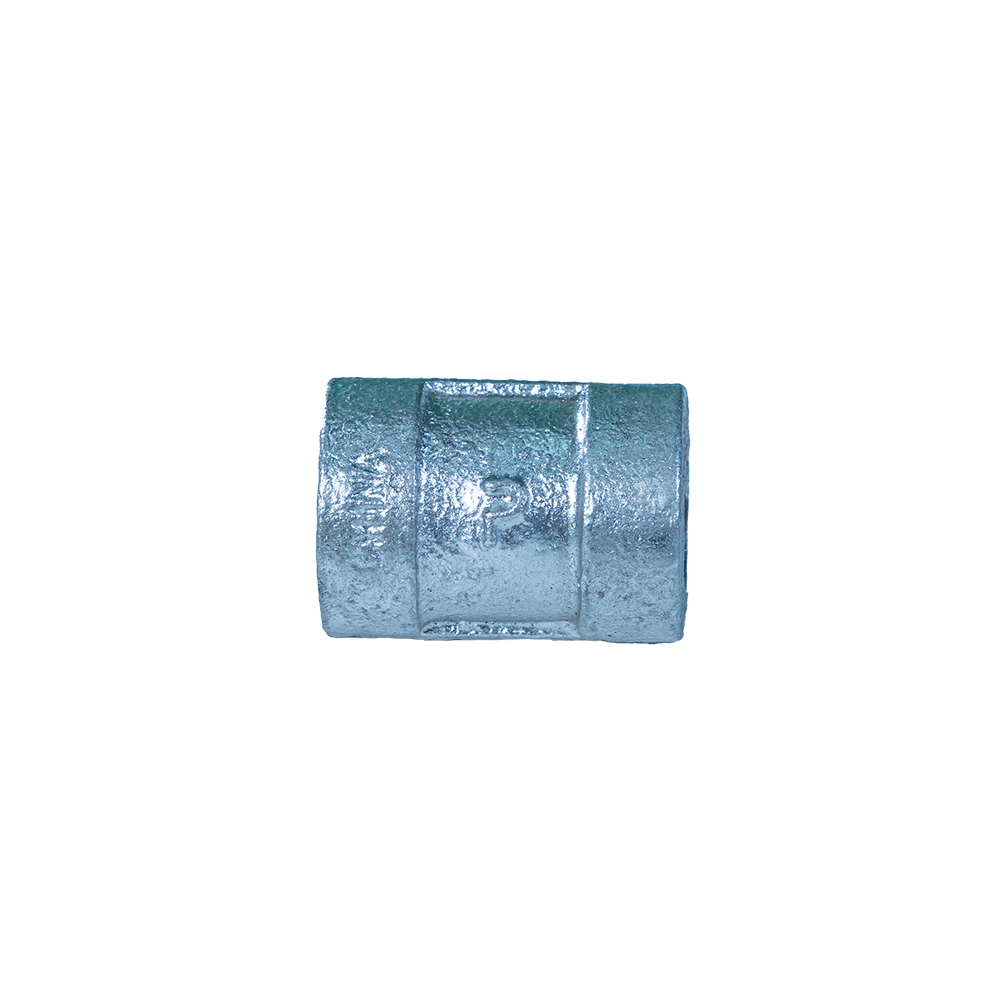

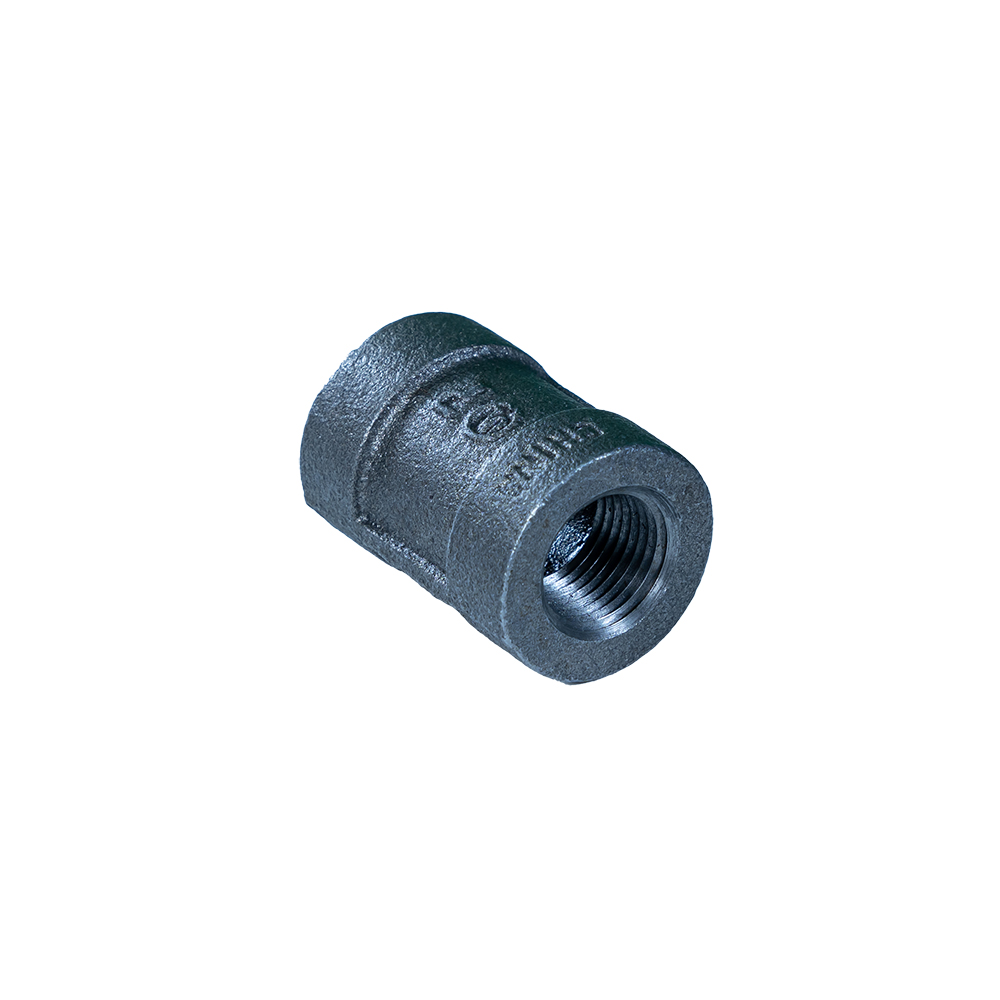

In an era where installers are juggling compressed timelines and stricter compliance, the humble malleable pipe fitting still does the quiet heavy lifting. This particular model—“Half Threaded Socket or Coupling UL Certificate,” made in 236 West Guangming Road, Langfang, Hebei, China—aims to shorten install time without skimping on testing. And yes, it’s a straight-shaped coupling with a female threaded connector; simple, dependable, easy to stock.

Industry snapshot and where it’s going

Installers are telling me lead times and quality assurance matter more than ever. Fire protection and HVAC contractors, in particular, want UL-listed, traceable hardware that threads cleanly and seals first try. Surprisingly, many customers say the short body of a half socket helps in cramped retrofits and meter rooms. The trend toward mixed-thread systems (NPT/BSPT) also keeps ticking upward, especially for export projects.

Typical applications

- Fire sprinkler laterals and standpipes (NFPA systems), pump rooms

- Heating loops, chilled water, and general process water

- Compressed air and utility gas lines (check local codes)

- Light industrial fluids and agriculture lines where a compact malleable pipe fitting saves space

Technical specifications (quick view)

| Parameter | Spec (≈ real-world) |

|---|---|

| Material | Malleable cast iron, ASTM A47/A47M or ASTM A197; annealed |

| Thread options | NPT per ASME B1.20.1; BSPT per ISO 7-1 |

| Size range | 1/2"–4" (other sizes by request) |

| Pressure rating | Up to 300 psi for water/air (service conditions apply) |

| Finish | Black or hot-dip galvanized (ASTM A153, Class B equiv.) |

| Temperature window | ≈ -20°C to 300°C, depending on media and sealant |

| Compliance | UL Listed; EN 10242 (malleable fittings) reference; ASME B16.3 Class 150 context |

From foundry to field: process and testing

Methodology is straightforward but crucial. Castings are poured (sand mold), then annealed to achieve malleability. Machining trims faces; threads are cut and gauged. Surface finishing—black oil or galvanizing—comes next. Each batch typically undergoes:

- Hydrostatic testing at ≈ 2.5× working pressure

- Dimensional and thread gauge checks (NPT/BSPT)

- Tensile and hardness sampling per material spec

- Salt-spray (when galvanized) for indicative corrosion resistance

Expected service life? Many installs run 25–40 years, sometimes longer, if media is clean and corrosion controls are in place. Actually, sealant choice and torque matter more than people admit.

Vendor comparison (what buyers ask me most)

| Criteria | Pannext Half Threaded Socket | Vendor A | Vendor B |

|---|---|---|---|

| UL Listing | Yes (current) | Varies by lot | Yes |

| Thread options | NPT & BSPT | NPT only | NPT & BSPT |

| Lead time | ≈ 2–4 weeks | ≈ 4–6 weeks | ≈ 3–5 weeks |

| Customization | Logo, special coatings | Limited | Logo only |

| QC transparency | Mill certs + test sheets | On request | Basic |

Customization and a quick case

Brand stamping, packaging, and galvanizing thickness tweaks are doable. One municipal retrofit swapped aging couplings with this malleable pipe fitting in a pump station; installers liked the thread accuracy—less dope, fewer reworks. Flow testing post-swap showed no leaks at 1.5× operating pressure.

Certifications, standards, and what to check

- UL Listed (verify current file in UL Product iQ)

- Material traceability to ASTM A47/A197

- Threads per ASME B1.20.1 (NPT) or ISO 7-1 (BSPT)

- Conformity with EN 10242 for malleable iron fittings

- System compatibility: ASME B16.3 Class 150 context; NFPA 13 for fire systems

To be honest, selection is simple: match thread standard, pick the finish, confirm pressure/temperature, and make sure your sealant and torque practice align with the spec sheet. Then it just… works.

A note on address and support

Origin: 236 West Guangming Road, Langfang, Hebei, China. Many buyers appreciate quick tech replies—small thing, big difference.

Citations

- ASME B1.20.1 – Pipe Threads (NPT)

- ISO 7-1 – Pipe threads where pressure-tight joints are made on the threads

- EN 10242 – Malleable cast iron fittings

- ASTM A47/A47M – Ferritic Malleable Iron Castings

- ASTM A153 – Zinc Coating (Hot-Dip)

- NFPA 13 – Installation of Sprinkler Systems

- UL Product iQ – Listings Database

Post time: Oct-02-2025