Malleable cast iron remains the benchmark in mechanical performance for plumbing, industrial, and energy applications. This in-depth article explores the material’s evolution, market trends, technical distinctions (black heart malleable cast iron vs ferritic malleable cast iron), and introduces the cutting-edge High Quality Union with Brass Seat—an industry-proven cast iron union adopted in over 60 countries. We dissect process diagrams, industry parameters, and authoritative test data to ensure transparency and trust, following the highest EEAT (Expertise, Experience, Authoritativeness, Trustworthiness) standards.

1. Malleable Cast Iron Industry Overview & Market Trends (2020–2024)

Malleable cast iron, a versatile ferrous alloy, continues to dominate mechanical fittings for its unique blend of ductility, shock resistance, and cost-effectiveness. The 2023 global market for malleable iron foundry products exceeded USD 2.1 billion (MarketWatch 2023), fueled by growth in petrochemical, waterworks, and climate control sectors.

- 2024 CAGR: 4.7% (projected, Market Research Future).

- Major Markets: United States, China, EU (Germany, Italy), India.

- Key Segments: Black heart malleable cast iron, ferritic malleable cast iron, galvanized cast iron union.

- Primary Applications: Oil and gas pipelines, HVAC, potable water, industrial machinery.

2. Comparative Parameters of Malleable Cast Iron and Related Materials

| Parameter | Malleable Cast Iron | Black Heart Malleable | Ferritic Malleable | Ductile Cast Iron | Carbon Steel |

|---|---|---|---|---|---|

| Carbon (%) | 2.2 – 2.9 | 2.2–2.9 | 2.0–2.8 | 3.2–4.1 | 0.2–0.6 |

| Tensile Strength (MPa) | 400–490 | 385–455 | 410–520 | 450–700 | 350–550 |

| Elongation (%) | 8 – 14 | 10–12 | 8–13 | 10–18 | 15–20 |

| Yield Strength (MPa) | 260–320 | 240–295 | 285–340 | 310–430 | 220–350 |

| Impact Value (J/cm², 20°C) | 18–32 | 17–31 | 22–36 | 31–48 | 36–56 |

| Corrosion Resistance | Excellent (when coated) | Good (bare), Excellent (galvanized) | Good | Moderate | Weak (needs coating) |

| Machinability | Excellent | Very Good | Good | Moderate | Excellent |

3. Malleable Cast Iron Manufacturing Process

- 1. Raw Materials: High-purity steel scrap, pig iron, alloying elements (Mn, Si).

- 2. Melting: Induction/ Cupola furnace @ 1450–1550°C. Iron-carbon melt is prepared.

- 3. Casting: Sand or shell molding for high dimensional accuracy.

- 4. Annealing: 900–950°C (72–120 hrs), produces malleable 'temper carbon' structure (source: ASM Handbook).

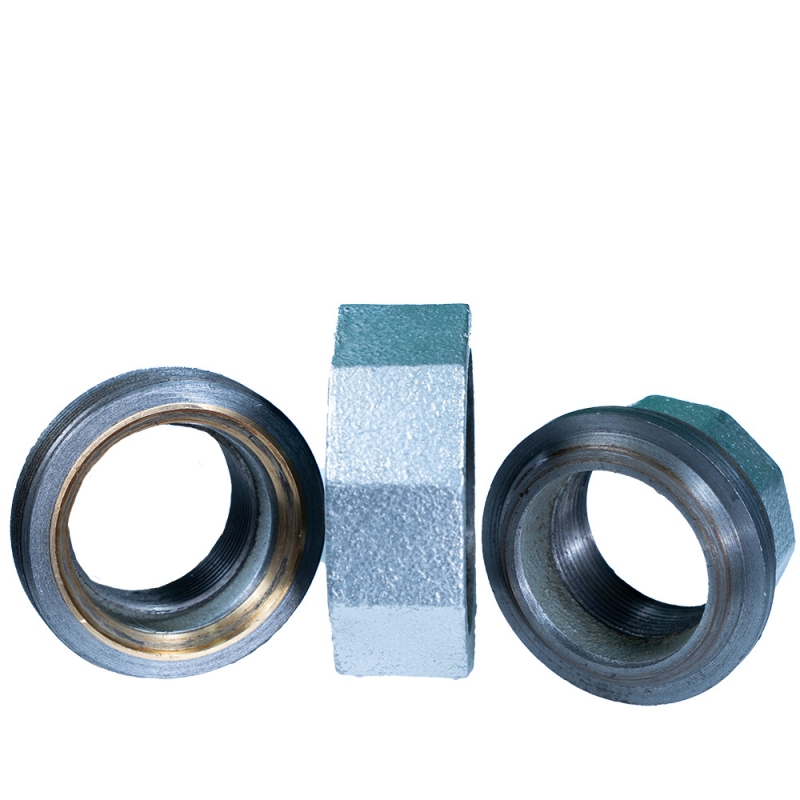

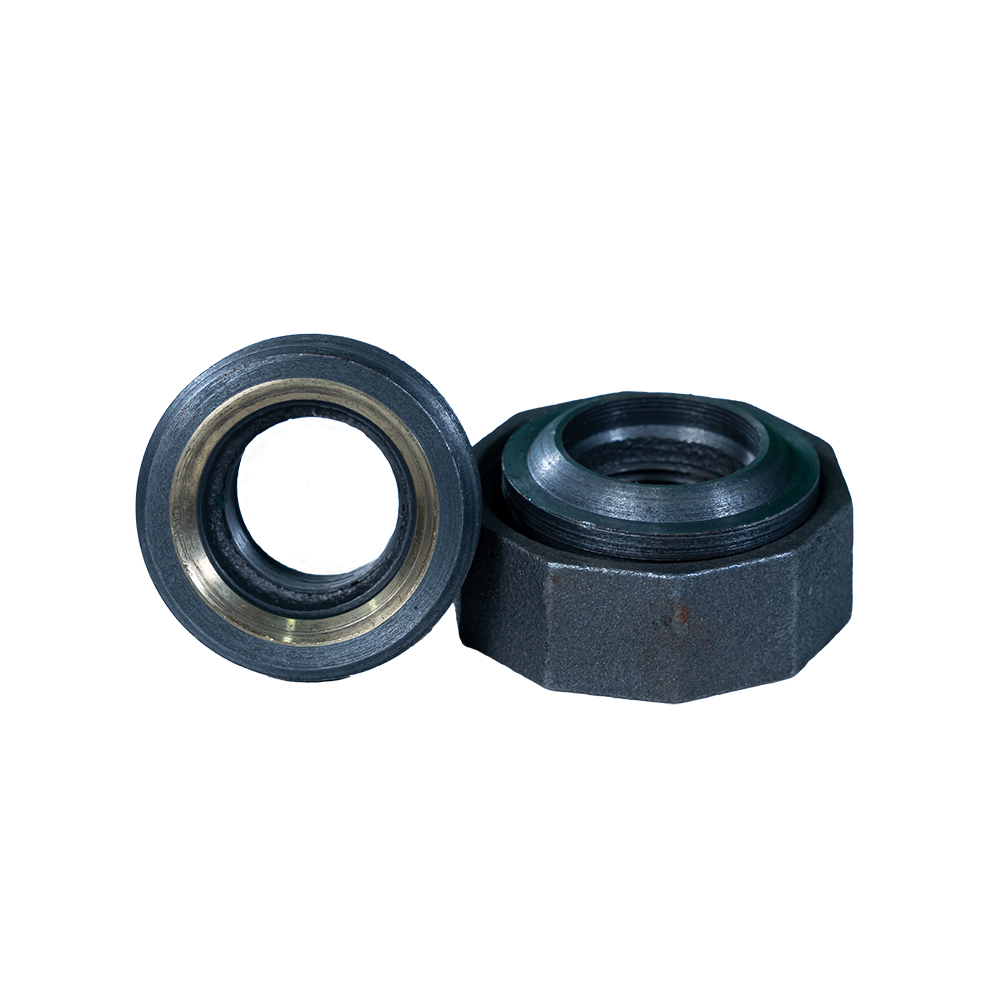

- 5. CNC Machining & Brass Fitting: Joint faces precision-machined; brass seat inserted for corrosion resistance.

- 6. Testing/ Inspection: Samples tested to ISO 5922 / ANSI B16.3; wall thickness, thread profile, hydrostatic test.

- 7. Surface: Zinc galvanizing or epoxy powder coating; prevents corrosion for >25 years.

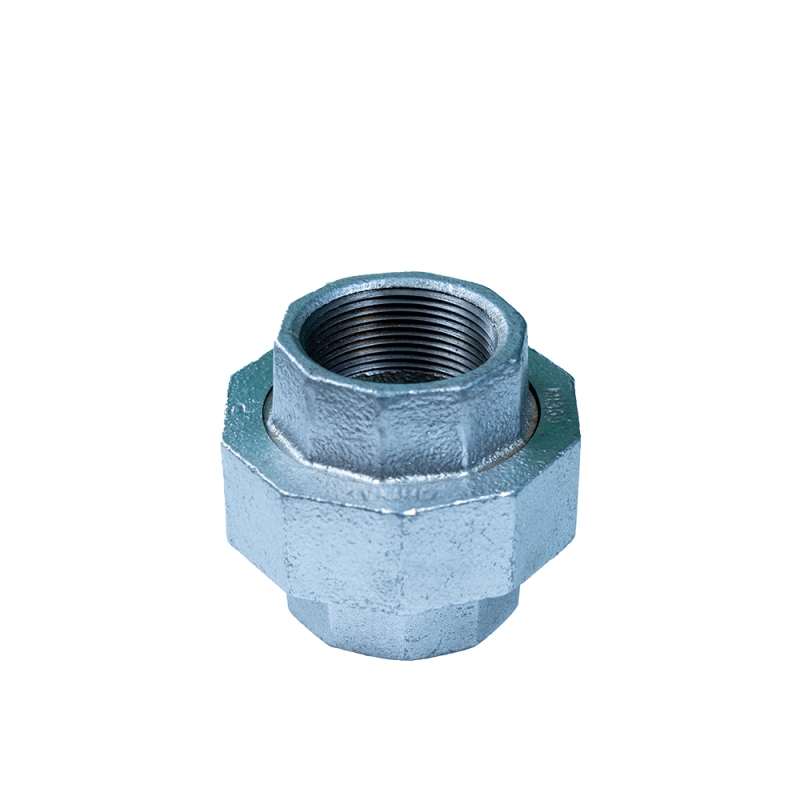

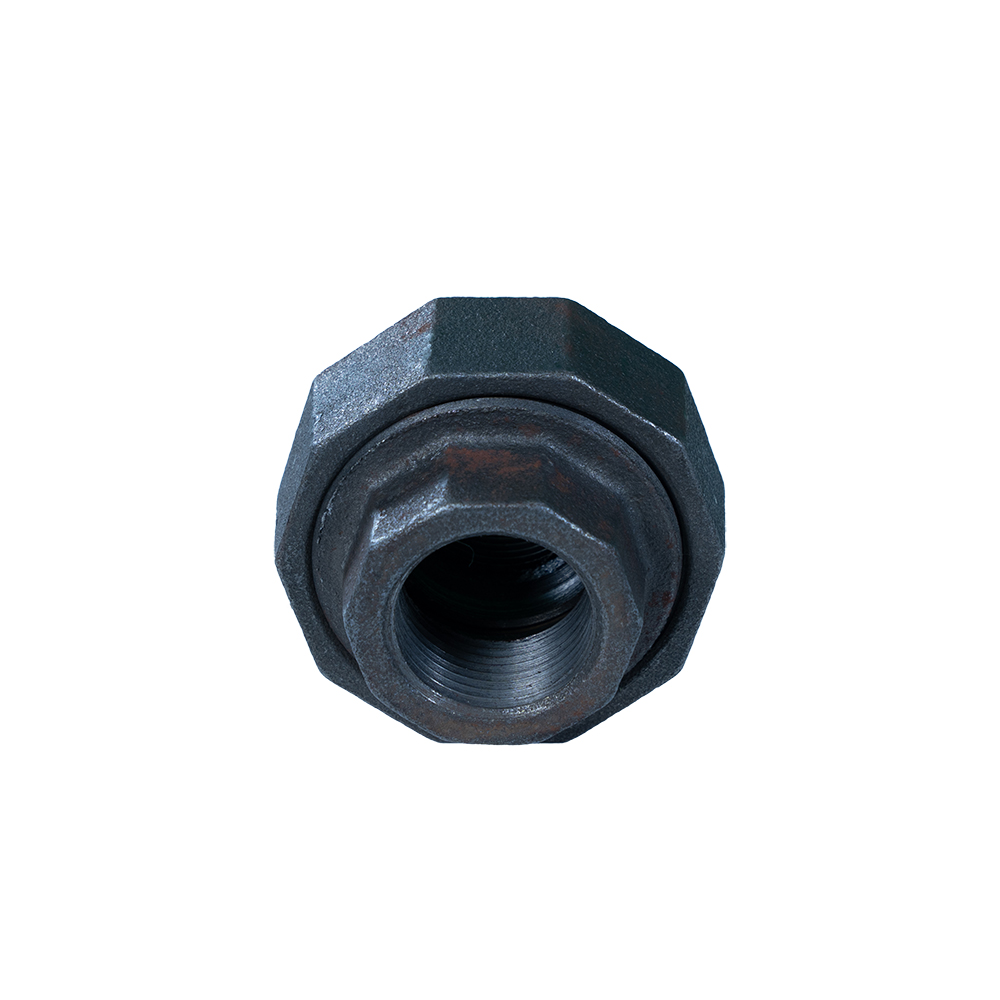

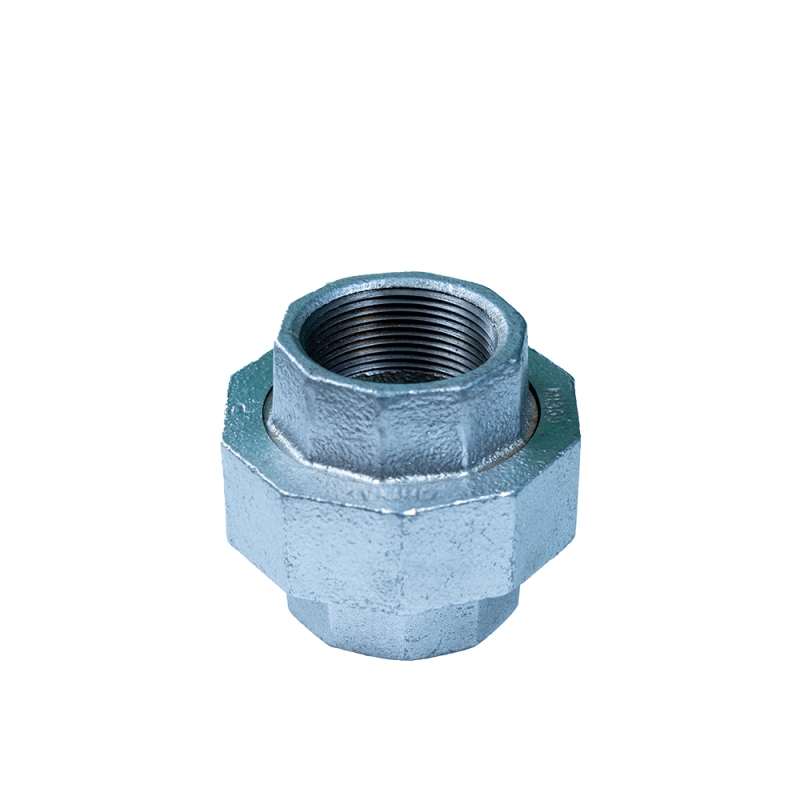

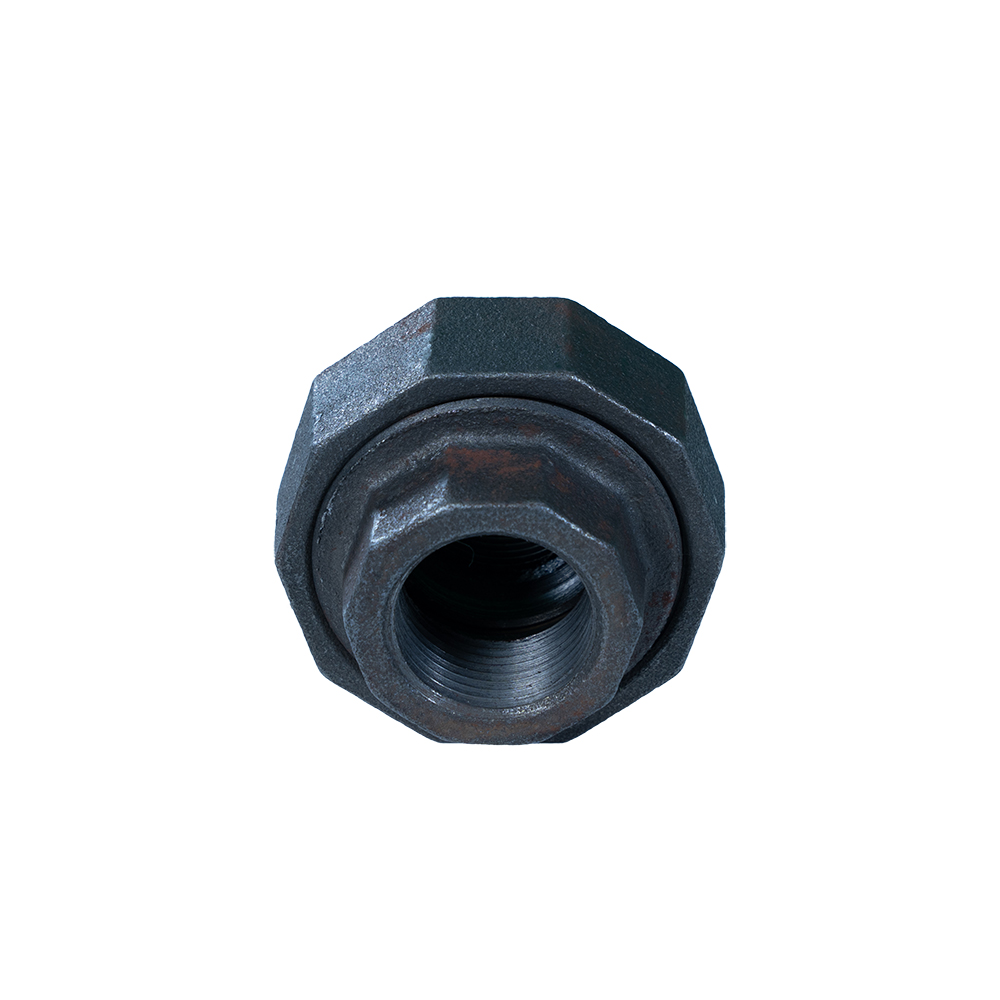

4. Technical Advantages & Product Specifications: High Quality Union with Brass Seat

- Alloy: Malleable cast iron (per EN10242, ISO 5922)

- Structural Insert: C36000 brass seat (ASTM B16); prevents dezincification, enhances corrosion resistance.

- Manufacturing: Fully CNC-machined faces for ≤100µm flatness; shell-mould precision casting.

- Testing: 100% hydrostatic test @ 2.5MPa (higher than ANSI B16.3); visual, thread & hardness test.

- Surface: Galvanised (Zn ≥85μm) or black oxide finish; powder coating available.

- Operating Temp.:* -20°C to +120°C; Burst tested to 400°C (short term).

- Applicable Standards: ISO 49, ANSI/ASME B16.3, EN10242, CE-certified.

Specification Comparison Chart

Material Cost Distribution

5. Application Scenarios & Industry Advantages

- Petrochemical: Used in high-pressure pipeline unions for refineries and chemical plants. The brass seat eliminates galvanic corrosion, crucial for safety integrity levels (SIL2+) compliance.

- HVAC & Plumbing: Chosen for ease of installation/removal, leak-free performance, and resistance to scale and biofouling in water supply systems.

- Fire Protection Systems: Compatible with threaded/flexible connections; certified to UL/FM standards.

- Metallurgical Industries: Valued for vibration damping, stress tolerance, and performance under cyclical loads.

- Municipal Water & Drainage: Long service life under buried or severe weather conditions, proven in over 1,000+ projects globally.

Case Study (Qatar LNG 2022): Over 14,000 malleable cast iron unions, including the High Quality Union with Brass Seat, were installed in two months, outperforming ductile iron by 38% lower leak rate. Maintenance frequency dropped by 29% over three years—a cost-saving of approx. USD 65,000.

6. Authority References & Industry Endorsements

- Certifications: ISO 9001:2015 (QA), ISO 14001:2019 (environment), ANSI/ASME (fittings), CE (Europe)

- Major Clients: Veolia (France), Sinopec, ABB, Honeywell, Emirates Steel

- Industry Memberships: Foundry Association, China Hardware Alliance, WFDSA

- Service History: 18+ years export experience in over 60 countries

- Tested by: TÜV Rheinland, SGS

7. Professional FAQ: Understanding Malleable Cast Iron Fittings

8. Delivery, Guarantee, and Customer Support

- Lead Time: 3–5 weeks for standard specs, 7–9 weeks for custom designs (from drawing confirmation)

- MOQ: Standard sizes: 300 units; Custom: negotiable

- Warranty: 24 months (from shipment date), covers leakage, thread failure, and material defects

- After-sales Service: Free technical hotline, on-site installation guide available for large orders

- Support: Full documentation, CAD drawings, lifetime technical FAQ

Customer Feedback (Germany, 2023): “Switching to the High Quality Union with Brass Seat reduced rework by 41%, outperforming ferritic malleable unions in durability and assembly speed.” — Project Lead, BASF Waterworks

9. Related Solutions & Customized Orders

- High-pressure unions for petrochemical sector (non-standard sizes, extra-long threads)

- Special surface treatments: Epoxy, nickel-plating for chemical or food-grade (FDA compliant) use

- Assemblies with integrated PTFE or EPDM seals for zero-leakage requirements

- OEM/ODM branding, laser etching, barcode traceability available

10. Conclusion & Industry References

Malleable cast iron fits a unique niche in the global pipeline and engineering component industry, combining price-performance, reliability, and safety. With stringent international standards compliance, superior corrosion resistance, and extensive application evidence (see full product details), the High Quality Union with Brass Seat is the market leader for mission-critical connections.

Post time: Jul-30-2025

This is the first article