Field Notes on the 1/4 NPT Elbow Landscape (and why the humble 180° elbow still matters)

If you’ve been hunting for a no-drama 1 4 npt 45 degree elbow, you’ve probably noticed something: the best pipe systems rarely use just one bend. In the real world, 45s, 90s, and 180s all play together—sample ports, bypass loops, and return lines. That’s why I took a hard look at Pannext’s 180 Degree Elbow (Black or Galvanized), made in Hebei, China, and how it fits alongside the 1/4 NPT 45° elbow many maintenance teams ask for.

What’s trending on shop floors

Three shifts I keep hearing: more malleable iron (for toughness and machinability), a move to hot-dip galvanizing for outdoor/compressed-air lines, and stricter thread-gage compliance. Buyers tell me they want NPT that actually seats—no more chasing micro-leaks with extra tape.

Spec snapshot: Pannext 180° Elbow, with 1/4 NPT in mind

| Product | 180 Degree Elbow — Black or Galvanized (Malleable iron fittings) |

| Material | Malleable cast iron, ASTM A197/A197M; Tensile ≥ 28.4 kg/mm² (≈279 MPa min) |

| Threads | NPT (ASME B1.20.1) & BSPT (ISO 7-1); Female, Head code: Equal |

| Pressure class | Class 150 P.S.I (hydrostatic test ≈ 1.5× at ~225 psi typical, lab-dependent) |

| Finish options | Black; Hot-dip galvanized (ASTM A153)—zinc layer ≈ 70–100 μm in practice |

| Size focus | 1/4" up to common line sizes; 1 4 npt 45 degree elbow typically paired for angled takeoffs |

| Origin | 236 West Guangming Road, Langfang, Hebei, China; Brand: P (Pannext) |

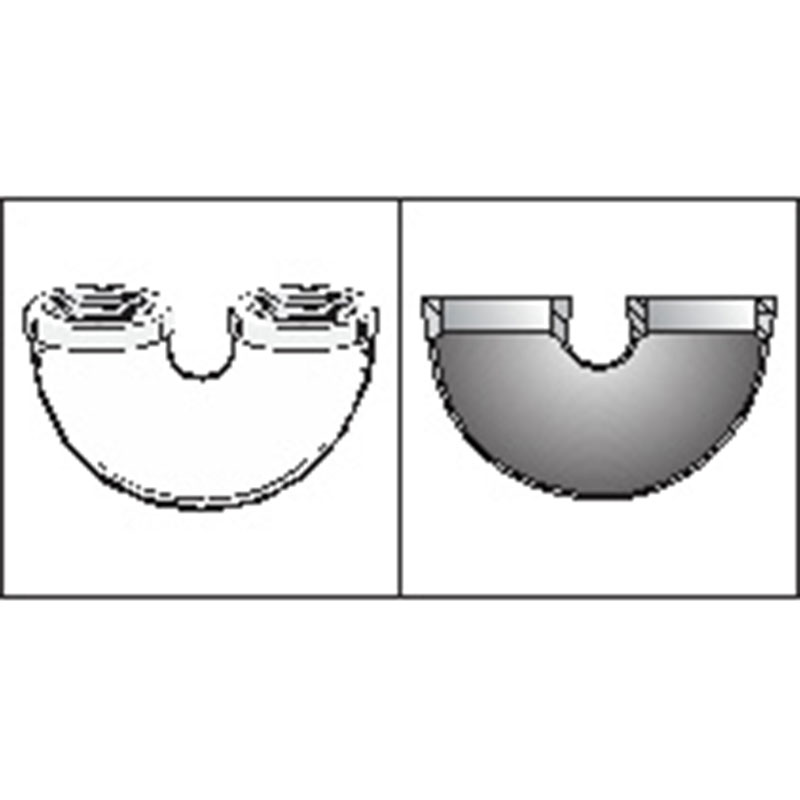

How it’s made (short version)

Raw iron goes through controlled cupola melting, precision sand casting, and annealing to reach that malleable structure. Machining aligns seat faces; NPT/BSPT threads are cut and checked with L1/L2 gauges. Galvanized parts take a hot-dip zinc bath, then passivation. QC wraps with hydro tests (~1.5× WP), dimensional checks, and salt spray per ASTM B117 (I’ve seen 72–96 h results on newer runs, though real-world use may vary).

Applications I keep seeing

- Compressed air drops and dryer bypass loops (180° returns + 1 4 npt 45 degree elbow for neat offsets)

- Glycol and water recirculation lines

- Light-duty process fluids in breweries, small food plants, and ag sprayer rigs

- Fire pump test loops and drain-returns (verify approvals!)

Why this pairing works

A 45° at 1/4 NPT is your tidy angle for gauges, sample ports, or instrument tees. The 180° elbow closes the loop—literally. Together they trim turbulence, reduce leak points, and (surprisingly often) save space in cramped skids.

Vendor comparison (field-notes style)

| Vendor | Thread Accuracy | Coating | Certs/Docs | Lead Time | Notes |

|---|---|---|---|---|---|

| Pannext (Hebei) | Consistent L1/L2 pass on NPT/BSPT | Black + hot-dip galvanized | ISO 9001, MTC; RoHS on request | Around 2–4 weeks | Good fit with 1 4 npt 45 degree elbow kits |

| Importer A | Mixed; occasional re-tapping needed | Electro-zinc (thinner) | Basic COC | Stock-dependent | Lower price, variable QC |

| OEM B | Tight threads; premium | HDG + epoxy option | Full test pack | 4–6 weeks | Great, but pricey |

Customization and QC

Typical options include NPT vs BSPT, black vs galvanized, private logo castings, and carton/barcode specs. Testing often includes hydro at ~225 psi for Class 150, random salt-spray checks, and thread gauges per lot. For fire service, many customers ask for UL/FM—confirm availability per size before you commit.

Mini case study

A midwest craft brewery swapped in galvanized 180° elbows with 1/4 NPT 45° taps for glycol sample points. Installation time dropped by ~18% (fewer unions), and they reported zero weeps after 12 months—no heroics, just better thread engagement and cleaner routing.

Bottom line

If you’re speccing a 1 4 npt 45 degree elbow for angles, don’t forget the loop-closure role of the 180°. The Pannext unit checks the boxes: malleable iron, true-to-gage NPT/BSPT, and a tough galvanized option for harsher bays. To be honest, that’s what keeps maintenance teams off the ladders.

Authoritative references

- ASME B1.20.1 – Pipe Threads, General Purpose (NPT)

- ISO 7-1 – Pipe threads where pressure-tight joints are made on the threads (BSPT)

- ASTM A197/A197M – Standard Specification for Cupola Malleable Iron

- ASTM A153/A153M – Zinc Coating (Hot-Dip) on Iron and Steel Hardware; ASTM B117 – Salt Spray Test

Post time: Oct-05-2025