A practical guide to standard 90 degree elbow dimensions in the field

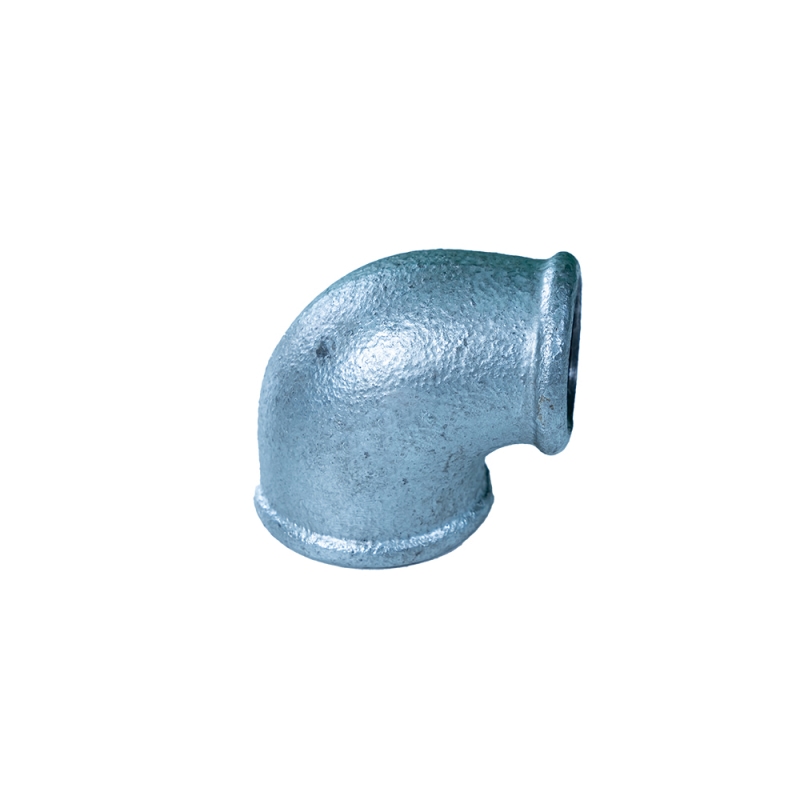

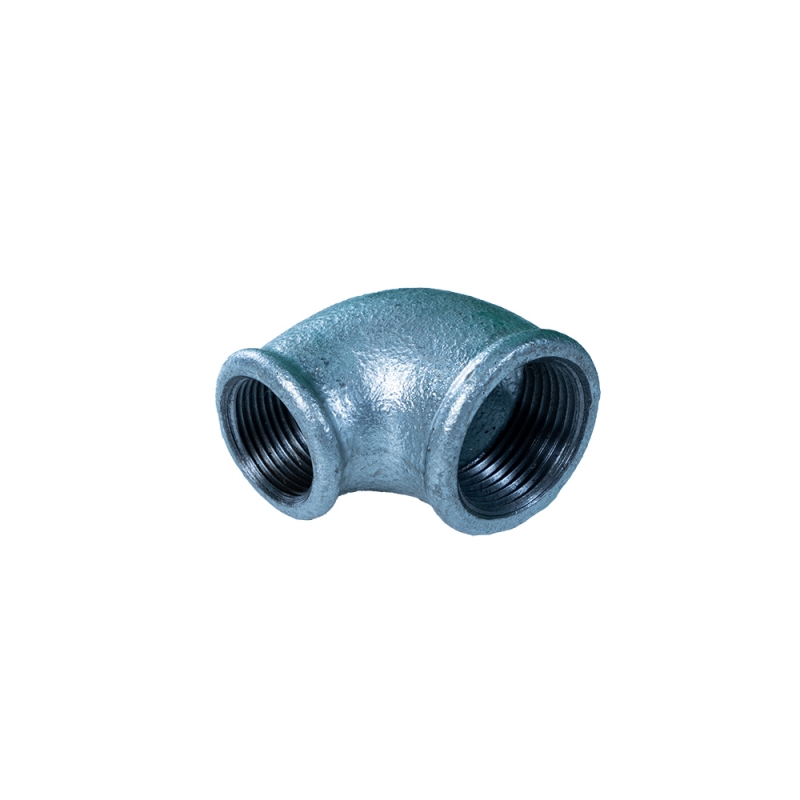

If you work around piping, you already know the humble 90° reducing elbow does a lot of heavy lifting. I spent a week in Langfang, Hebei—236 West Guangming Road to be exact—walking a line that turns out beaded malleable cast iron elbows, and the shop-floor reality honestly tells you more than any glossy brochure ever will. The star here is the 90° Reducing Elbow Beaded Malleable cast iron, rated Class 150 to BS/EN. It’s the one you reach for when a line needs to turn, downsize, and keep pressure and threads happy.

What makes this elbow useful

It connects two different pipe sizes by threaded ends (usually BSPT to ISO 7‑1) and turns the flow by 90°. The beaded profile adds rigidity and, yes, it looks neat on exposed runs. Many customers say they choose it for corrosion resistance and consistent threads—surprisingly, the little things like clean threads save the most time on site. The manufacturer runs 100% dimensional checks, which matters when you’re chasing standard 90 degree elbow dimensions for clash-free BIM layouts.

Typical specs (quick reference)

| Size (BSPT) | Ends (D1×D2) | Center-to-face C (≈ mm) | Bead OD B (≈ mm) | Pressure/Temp | Standard |

|---|---|---|---|---|---|

| 1/2" × 3/8" | DN15 × DN10 | ≈ 30 | ≈ 38 | PN16/Class 150 up to ~120°C | EN 10242, ISO 7‑1 |

| 3/4" × 1/2" | DN20 × DN15 | ≈ 36 | ≈ 45 | PN16/Class 150 | EN 10242, ISO 7‑1 |

| 1" × 3/4" | DN25 × DN20 | ≈ 42 | ≈ 54 | PN16/Class 150 | EN 10242, ISO 7‑1 |

| 2" × 1-1/2" | DN50 × DN40 | ≈ 72 | ≈ 82 | PN16/Class 150 | EN 10242, ISO 7‑1 |

Dimensions are typical values for guidance; real-world use may vary by coating, thread class, and supplier tolerances.

Materials, process, and tests (shop-floor notes)

- Malleable cast iron per ASTM A197, with controlled annealing for ductility.

- Shot-blasted surface, machining on CNC lathes, threads to ISO 7‑1 (BSPT). Optional hot-dip galvanizing to ISO 1461.

- Pressure test: typical 1.5× design (e.g., up to ~24 bar hydro). Torque verification on threads; 100% dimensional inspection.

- Salt-spray on galvanized batches: around 200 h (ISO 9227) in our observed runs.

- Expected service life: 25–50 years in water/HVAC; gas lines depend on media and maintenance.

Where it’s used and why it’s trending

Water supply, natural gas, central heating, and yes, plant utilities in food and pharma (non-product-contact lines). I’ve also seen them on agricultural rigs and aerospace ground support. The trend? Designers standardize on a short list of standard 90 degree elbow dimensions to reduce spares, and they want verifiable standards (EN 10242, ASME B16.3 compatibility) plus clean galvanizing that won’t flake.

Vendor snapshot (what buyers compare)

| Vendor | Certs/Standards | MOQ | Coating | Lead time | Customization |

|---|---|---|---|---|---|

| Pannext (Langfang) | EN 10242, ISO 7‑1; factory 100% dimension check | Flexible | Black or HDG | ≈ 3–5 weeks | Yes: odd reductions, logos |

| EU Brand A | EN 10242, CE | Moderate | HDG focus | 4–7 weeks | Limited |

| Local Foundry B | Shop certs; mixed docs | Low | Black, paint | 1–3 weeks | Variable |

Customization and a quick case

Need odd reductions, private-label beads, or special coatings? It’s doable. One facilities team swapped 3/4"×1/2" elbows on a mixed-metal retrofit; by matching standard 90 degree elbow dimensions and sticking with ISO 7‑1 threads, the weekend shutdown finished 6 hours early. To be honest, the faster thread start and clean galvanizing helped more than they expected.

Bottom line

Pick a vendor that publishes tolerances, threads to ISO 7‑1, and documents EN 10242 compliance. The rest—finish quality, lead time, and dimensional repeatability—decides how your install day goes.

Authoritative references

- EN 10242: Malleable cast iron fittings — Requirements and dimensions.

- ISO 7‑1: Pipe threads where pressure-tight joints are made on the threads.

- ASME B16.3: Malleable Iron Threaded Fittings, Class 150.

- ASTM A197/A197M: Standard Specification for Cupola Malleable Iron.

- ISO 1461 & ISO 9227: Hot-dip galvanizing and salt spray testing.

Post time: Oct-07-2025