Durable Black Iron Unions and Malleable Iron Pipe Fittings for Industrial Piping

ward malleable iron fittings,welding malleable iron pipe fittings,black iron reducing tee,black iron union,black iron union fitting are key solutions in the General equipment manufacturing industry, specifically within Manufacturing of valves and pipeline accessories and Manufacturing of cast iron pipe fittings. This article explores how Langfang Pannext Pipe Fitting Co., Ltd. supports professionals with durable, high-performance products, and explains why these products are an ideal choice for businesses in these sectors.

Table of Contents

- ward malleable iron fittings, welding malleable iron pipe fittings, black iron reducing tee, black iron union, black iron union fitting Overview

- Benefits & Use Cases of ward malleable iron fittings, welding malleable iron pipe fittings, black iron reducing tee, black iron union, black iron union fitting in Manufacturing of cast iron pipe fittings

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in General equipment manufacturing industry

- Conclusion on ward malleable iron fittings, welding malleable iron pipe fittings, black iron reducing tee, black iron union, black iron union fitting from Langfang Pannext Pipe Fitting Co., Ltd.

ward malleable iron fittings, welding malleable iron pipe fittings, black iron reducing tee, black iron union, black iron union fitting Overview

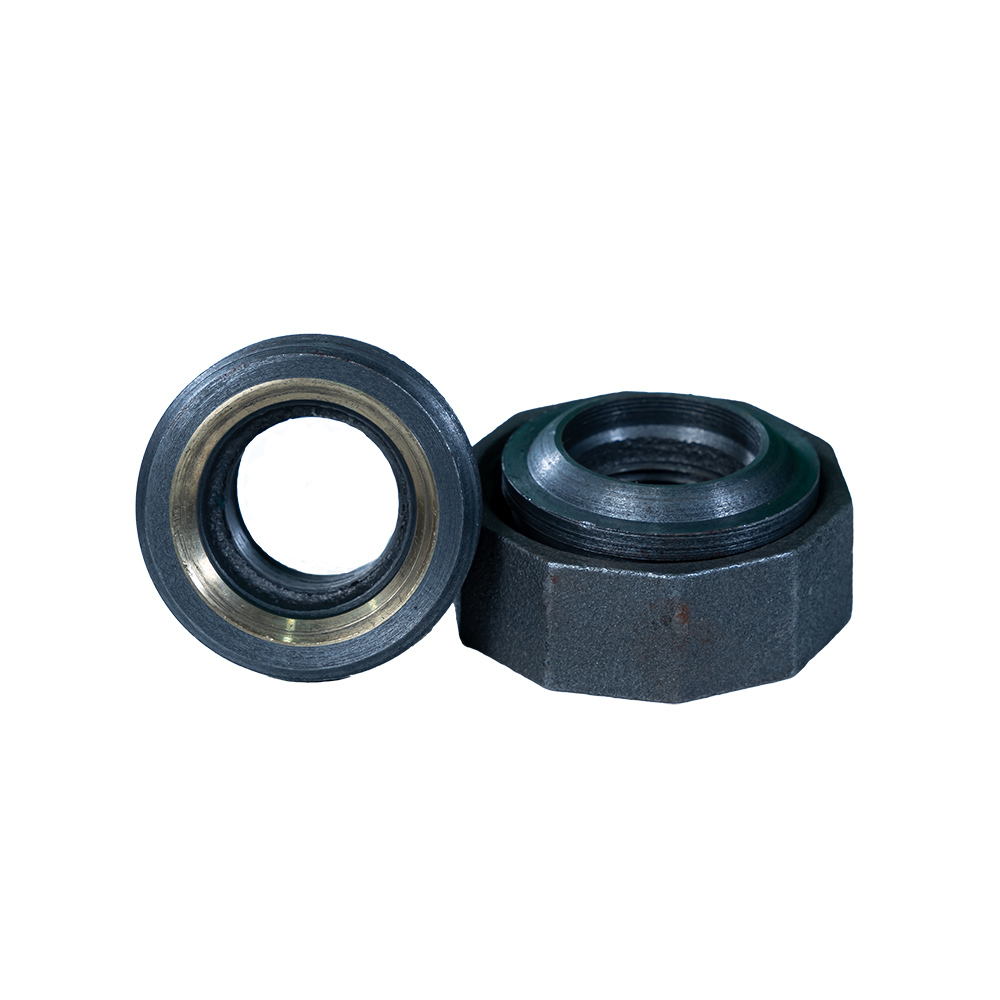

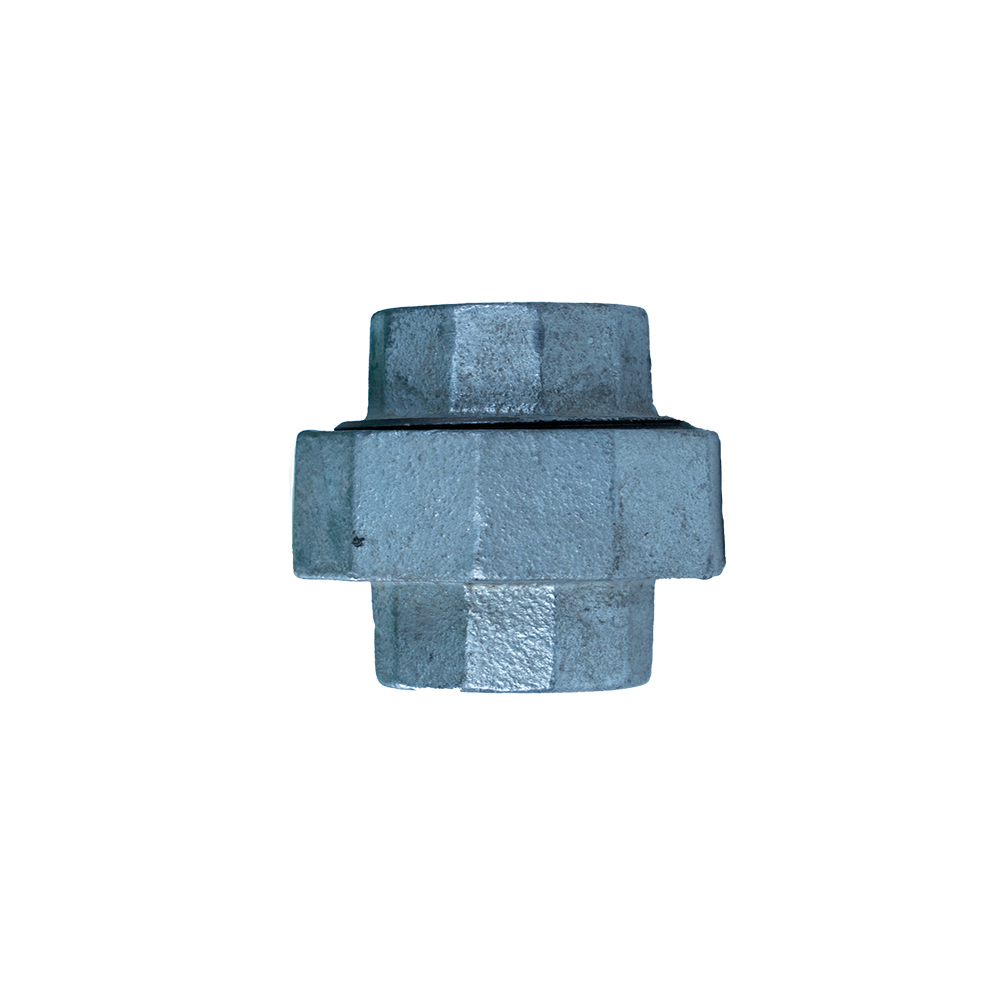

In industrial piping, malleable iron fittings deliver proven strength, machinability, and thread integrity across air, gas, steam, water, and oil services. Products such as the black iron reducing tee, black iron union, and black iron union fitting are typically produced to recognized standards like ASME B16.3/B16.39 for threaded fittings and unions, with NPT or BSPT threads (ASME B1.20.1/ISO 7-1). A union with a brass seat—like the solution offered by Langfang Pannext Pipe Fitting Co., Ltd.—helps ensure a tight, repeatable seal and easier makeup/disassembly, reducing galling and thread wear. While “welding malleable iron pipe fittings” is a common search term, in practice these fittings are predominantly used as threaded interfaces within systems that may include welded pipe spools.

Langfang Pannext Pipe Fitting Co., Ltd. manufactures a broad range of ward malleable iron fittings and black iron accessories to Class 150/300 service requirements, with options for black or galvanized finishes and precision-machined threads. In a recent factory utility upgrade, a Pannext brass-seat black iron union fitting enabled maintenance crews to isolate components without cutting the line—shortening change-outs and protecting upstream threads. For B2B buyers balancing reliability, availability, and lifetime cost, this portfolio checks all the boxes: dependable metallurgy, consistent dimensions, and fast procurement support.

Benefits & Use Cases of ward malleable iron fittings, welding malleable iron pipe fittings, black iron reducing tee, black iron union, black iron union fitting in Manufacturing of cast iron pipe fittings

For OEMs and integrators in the Manufacturing of cast iron pipe fittings, versatility and maintainability are essential. A black iron reducing tee is ideal for downsizing branches on compressed-air headers, steam tracing, and utility drops, while the black iron union provides a robust break point for instrumentation, valves, pumps, and meters. In skids that combine welded mainlines with threaded terminations, ward malleable iron fittings bridge welded spools to serviceable components, allowing safe isolation, rapid replacement, and leak-tight reconnection.

Langfang Pannext Pipe Fitting Co., Ltd. focuses on dimensional consistency, thread precision, and seat quality across its black iron union fitting range. The brass-seat union design helps maintain sealing integrity over multiple cycles, mitigating the common challenges of galling or thread damage during frequent maintenance. For global buyers, options for NPT and BSPT threading simplify export programs and multi-region builds. Whether you are assembling gas distribution manifolds, HVAC mechanical rooms, or industrial water treatment systems, Pannext’s portfolio of ward malleable iron fittings, black iron reducing tees, and unions supports repeatable assembly and lower field labor. The result is higher uptime and a cleaner bill of materials with fewer adapters and rework.

Cost, Maintenance & User Experience

Total cost of ownership hinges on more than unit price. With malleable iron, the right union and reducing tee can cut installation time, reduce leak remediation, and protect critical assets. The Pannext black iron union fitting with a brass seat is engineered for repeated assembly without excessive torque, which helps preserve threads and sealing faces—lowering consumable use (tape/dope) and minimizing rework. Standardized SKUs across black iron union and black iron reducing tee configurations streamline inventory and simplify technician training.

Industrial buyers report smoother fit-up and fewer callbacks when switching to precision-machined ward malleable iron fittings from Langfang Pannext Pipe Fitting Co., Ltd. Maintenance teams appreciate that unions act as service joints, eliminating the need to cut out sections during equipment swaps. Over a multi-year lifecycle, this yields measurable ROI: faster shutdowns, reduced leakage risk, and extended component life. For manufacturers of valves and pipeline accessories, dependable threads and consistent tolerances translate into cleaner assemblies, better QA pass rates, and predictable torque values during factory acceptance testing.

Sustainability & Market Trends in General equipment manufacturing industry

Across the General equipment manufacturing industry, sustainability and compliance expectations are rising. Malleable iron is inherently recyclable, and responsible foundry practices—optimized melting, reclaiming sand, and efficient machining—help reduce the embodied impact of fittings. Buyers also prioritize durability: long-lived black iron unions and reducing tees lower replacement frequency, trimming waste and transport emissions over time. On the regulatory front, consistent material traceability and thread conformity (NPT/BSPT) support cross-border projects and smoother documentation in EPC workflows.

Langfang Pannext Pipe Fitting Co., Ltd. invests in process control, surface finishing quality, and packaging optimization to reduce damage and scrap in transit. The company’s forward-leaning approach—quality systems aligned with international best practices, responsive documentation, and flexible production slots—aligns with market trends favoring shorter lead times and dependable repeatability. For projects blending welded pipework with threaded takeoffs, “welding malleable iron pipe fittings” scenarios are increasingly specified as welded-to-threaded transitions, where unions and reducing tees enable sustainable maintenance strategies and circularity through component reuse.

Conclusion on ward malleable iron fittings, welding malleable iron pipe fittings, black iron reducing tee, black iron union, black iron union fitting from Langfang Pannext Pipe Fitting Co., Ltd.

From utility headers to process skids, ward malleable iron fittings deliver reliable performance where it counts. A black iron reducing tee simplifies branch sizing, while a black iron union or black iron union fitting with a brass seat ensures fast, leak-tight service joints. Backed by Langfang Pannext Pipe Fitting Co., Ltd., these components provide consistency, availability, and value for the Manufacturing of valves and pipeline accessories and Manufacturing of cast iron pipe fittings.

Contact us: email: fanda@pannext-casting.com

Visit our website: https://www.pannextfittings.com

Post time: Oct-05-2025