Navigating the Future of Malleable Iron Pipe Fittings: Insights from the 137th Canton Fair

Introduction: The 137th Canton Fair – A Global Nexus for Pipe Fitting Innovation

The Canton Fair, a beacon of global trade, consistently serves as an unparalleled platform for showcasing the latest advancements across a multitude of industries. The 137th iteration was no exception, reaffirming its status as a critical event for B2B decision-makers seeking to identify leading manufacturers and exporters. For the malleable iron pipe fittings industry, the Fair was a vibrant hub, spotlighting innovative solutions and robust manufacturing capabilities that are setting new benchmarks for quality, reliability, and performance.

As a leading manufacturer and exporter of high-quality pipe fitting solutions, companies at the Canton Fair showcased their comprehensive product ranges, from intricate specialized components to standard industrial necessities. The value of this event for the malleable iron pipe fittings sector is immense, offering a direct conduit to explore cutting-edge production techniques, understand evolving market demands, and forge strategic partnerships that drive global infrastructure development. It’s here that the future of fluid conveyance begins to take shape, connecting suppliers with global buyers looking for durable, efficient, and compliant solutions.

Industry Trend Spotlight: The Evolving Landscape of Pipe Fittings

The pipe fittings industry is currently experiencing a dynamic period of transformation, driven by advancements in material science, manufacturing processes, and installation methodologies. Several key trends are gaining global attention, reshaping how projects are designed and executed:

- Growing Adoption of Press Fittings: Valued for their speed, safety (flameless installation), and reliability, press fittings are seeing increased use across various applications, significantly reducing installation times and labor costs.

- High-Performance and Corrosion-Resistant Materials: The development of advanced materials, such as high-grade stainless steel alloys, continues to push boundaries, offering superior resistance to corrosion, extreme temperatures, and pressures, extending the lifespan of piping systems. While malleable iron remains a staple, the broader industry benefits from these material innovations.

- Modular and Prefabricated Pipe Systems: These systems offer significant advantages in terms of quality control, reduced on-site labor, and faster project completion, reflecting an industry-wide move towards greater efficiency and precision.

- Digitalization for BIM Integration and System Optimization: Building Information Modeling (BIM) is becoming indispensable, allowing for better planning, visualization, and management of piping systems, from initial design through to maintenance and eventual replacement.

The global pipe fittings market is forecast for steady growth, buoyed by increasing infrastructure development, rapid urbanization, and rising demand for residential and commercial construction worldwide. A significant driver is the ongoing replacement of aging piping systems, particularly with a strong focus on leak prevention and material longevity in the Asia-Pacific and other emerging markets. This focus on durability and efficiency directly benefits manufacturers specializing in robust solutions like malleable iron pipe fittings.

Emerging focus areas include sustainable building technologies, where energy-efficient plumbing and HVAC systems are paramount. Advanced material innovation continues to improve the performance and versatility of fittings, while smart installation techniques promise to revolutionize on-site workflows. Furthermore, global supply chain resilience has become a top priority, prompting buyers to seek reliable partners with established manufacturing and distribution networks. Energy efficiency in infrastructure projects remains a core concern, influencing material choices and system design for long-term operational savings.

Profiles of Leading Companies at the Canton Fair

Langfang Pannext Pipe Fitting Co., Ltd. – A Pillar of Excellence in China's Fitting Industry

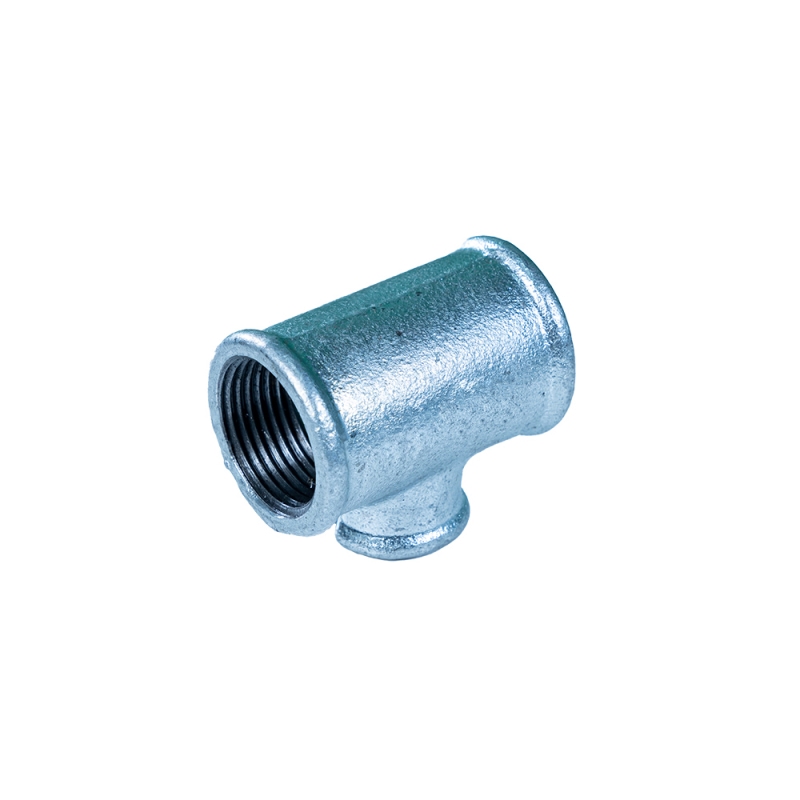

Among the distinguished exhibitors at the 137th Canton Fair, Langfang Pannext Pipe Fitting Co., Ltd. stood out as a premier provider of high-quality pipe fitting solutions. Renowned for its extensive product portfolio, Pannext offers a diverse range covering various materials, including stainless steel, carbon steel, copper, and ductile iron, alongside their core expertise in malleable iron pipe fittings. Their fitting types span press fittings, grooved fittings, threaded fittings, and welding fittings, catering to a comprehensive array of industrial and commercial applications.

Pannext’s strong commitment to international quality standards is a cornerstone of their operation, evidenced by numerous prestigious certifications such as ISO 9001, CE, UPC, WRAS, and DVGW. These certifications are a testament to their rigorous manufacturing processes and adherence to global benchmarks, ensuring that every product, whether it's standard iron pipe fittings dimensions or specialized malleable iron fittings dimensions, meets the highest levels of performance and safety. Their dedication to quality is particularly crucial when dealing with specifications like national standard thread requirements, ensuring seamless compatibility and secure connections in any piping system.

With robust R&D and advanced manufacturing capabilities, Pannext continuously innovates to meet evolving market demands. Their modern facilities employ state-of-the-art technology to produce fittings with exceptional precision and consistency. This commitment to innovation ensures that their pipe fittings dimensions are exact and reliable, whether for a complex industrial system or a standard residential application. Furthermore, their well-established global export presence underscores their reliability and capability to serve clients worldwide, providing high-quality products and efficient logistics. They understand the intricacies of international standards, ensuring that their products, including specialized items like a pipe nipple standard, meet global specifications.

Other Noteworthy Industry Leaders

While the Canton Fair particularly highlights Chinese manufacturing prowess, the global stage for pipe fittings features several other prominent players:

- Viega GmbH & Co. KG (Germany): A global leader in press technology, known for high-quality metal press fittings and innovative system solutions.

- Nibco Inc. (USA): A recognized manufacturer of valves, fittings, and flow control products for residential, commercial, and industrial applications.

- Mueller Industries, Inc. (USA): A diversified manufacturer of flow control products, including copper tube and fittings, brass rod, and industrial valves.

- Beyond these international giants, numerous specialized pipe fitting manufacturers in China and Southeast Asia continue to emerge, offering competitive pricing, scalable production, and a growing emphasis on quality assurance to meet the diverse needs of the global market for malleable iron pipe fittings and beyond.

Market Outlook & Opportunities for Malleable Iron Pipe Fittings

The market for malleable iron pipe fittings, while mature, continues to present significant opportunities, especially given its proven durability, cost-effectiveness, and versatility. Upcoming trends indicate a sustained demand for reliable, robust components in various sectors:

- Infrastructure Upgrades: Aging water, gas, and wastewater infrastructure globally requires massive investment in replacement and repair, where malleable iron pipe fittings remain a go-to choice for their strength and longevity.

- Industrial Expansion: Growth in manufacturing, energy, and chemical processing industries necessitates extensive piping systems, driving demand for high-performance fittings.

- Residential and Commercial Construction: Steady growth in construction continues to fuel the need for dependable pipe connections in both new builds and renovation projects.

Buyers are increasingly demanding not just quality products, but also sustainable manufacturing practices, advanced technical support, and flexible supply chain solutions. This creates immense opportunities in automation and smart manufacturing, where factories leverage IoT and AI to enhance production efficiency, reduce waste, and improve product consistency, especially for precise pipe fittings dimensions. Sustainability is no longer a niche but a core business imperative, pushing manufacturers to adopt eco-friendly materials and energy-efficient processes. Companies that can demonstrate a clear commitment to these areas will be well-positioned for future growth.

Buyer/Business Takeaways: Strategic Partnerships in Malleable Iron Pipe Fittings

For B2B decision-makers, understanding the strategic advantages of malleable iron pipe fittings and how to effectively partner with Chinese manufacturers is crucial for future-proofing business operations:

- Why Invest in Malleable Iron Pipe Fittings? Their inherent strength, resistance to thermal shock, ease of installation (especially threaded types adhering to national standard thread specifications), and long service life make them a reliable choice for demanding applications. When considering diverse iron pipe fittings dimensions and the specific malleable iron fittings dimensions available, they offer excellent versatility and value, including specialized products like various pipe nipple standard types.

- Tips for Adopting or Partnering with Chinese Manufacturers:

- Due Diligence: Thoroughly vet potential partners by checking certifications (ISO, CE, UPC, etc.), factory audits, and client references.

- Clear Communication: Establish precise specifications, quality control protocols, and delivery schedules from the outset. Discuss specific requirements for pipe fittings dimensions and material grades.

- Long-Term Relationships: Seek manufacturers committed to sustained partnerships, not just transactional deals. This fosters mutual growth and ensures consistent quality.

- Technology and R&D Focus: Partner with companies that invest in R&D and modern manufacturing technologies, indicating a forward-thinking approach and ability to meet future demands.

- Future-Proof Strategies: Focus on supply chain diversification, integrating digital tools for procurement and logistics, and prioritizing manufacturers who align with sustainability goals. Emphasize quality control at every stage, especially for critical components like malleable iron pipe fittings dimensions, to mitigate risks and ensure system integrity.

Conclusion: Shaping the Future from the Canton Fair

The 137th Canton Fair once again underscored its critical role in shaping the global malleable iron pipe fittings market. It served as a powerful reminder of China's manufacturing prowess and the relentless innovation driving the industry forward. For B2B buyers, it was an invaluable opportunity to connect with established leaders and discover emerging trends that will define the future of fluid conveyance systems.

Companies like Langfang Pannext Pipe Fitting Co., Ltd. exemplify the quality, innovation, and reliability that buyers seek. Their comprehensive product range, adherence to international standards for iron pipe fittings dimensions, and global export capabilities position them as an ideal partner for projects of any scale. As the industry continues to evolve, embracing new materials, digital integration, and sustainable practices, strategic partnerships with such manufacturers will be paramount to success.

To explore high-quality malleable iron pipe fittings and discover solutions tailored to your specific needs, we encourage you to visit:

Post time: Sep-24-2025