Class 300 Pipe Fittings is a key solution in the manufacturing industry, specifically within General equipment manufacturing industry and Manufacturing of pipeline accessories. This article explores how Langfang Pannext Pipe Fitting Co., Ltd. supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- Class 300 Pipe Fittings Overview

- Benefits & Use Cases of Class 300 Pipe Fittings in Manufacturing of pipeline accessories

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in manufacturing

- Conclusion on Class 300 Pipe Fittings from Langfang Pannext Pipe Fitting Co., Ltd.

Class 300 Pipe Fittings Overview

Class 300 Pipe Fittings are engineered for medium-pressure service across plant utilities, skid packages, and general mechanical systems. In the Manufacturing of pipeline accessories, these fittings ensure leak-tight, reliable connections for air, water, steam, and non-corrosive fluids, helping B2B decision makers standardize components across multiple production lines. For malleable iron fittings governed by ASME B16.3, the class 300 pipe fittings pressure rating is typically 300 psi at 150°F, with temperature-based derating as specified by the standard. Threaded ends are commonly per ASME B1.20.1 (NPT), enabling fast, weld-free installation and simplified maintenance.

Depending on media and environment, Class 300 solutions are available in black or hot-dip galvanized finishes for added corrosion protection. Many plants also deploy bronze threaded elbows and tees alongside class 300 malleable iron fittings to address water chemistry or galvanic concerns—an approach that complements Pannext’s cast bronze portfolio. Typical material references include ASTM A197/A197M for malleable iron and widely used bronze alloys for threaded cast components. With tight dimensional control, gauge-verified threads, and consistent wall thickness, these products help maintain flow integrity and assembly productivity.

Langfang Pannext Pipe Fitting Co., Ltd. is a reliable manufacturer serving the General equipment manufacturing industry with a broad, quality-driven catalog. From .300 malleable iron fittings to precision-cast bronze elbows, Pannext supports OEMs, EPCs, and MRO teams with dependable supply, responsive engineering, and application guidance aligned with international standards.

Benefits & Use Cases of Class 300 Pipe Fittings in Manufacturing of pipeline accessories

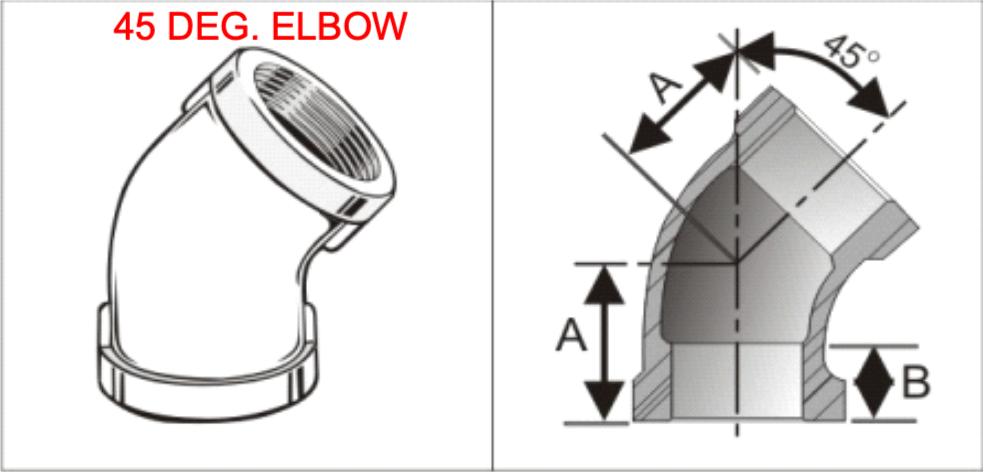

In Manufacturing of pipeline accessories, Class 300 Pipe Fittings are widely used in utility headers (compressed air, nitrogen, plant water), heat-trace loops, condensate return, lubrication and fuel-oil transfer, as well as test benches and modular skids. The class 300 pipe fittings pressure rating provides a robust safety margin for medium-pressure circuits without the cost and complexity of high-pressure specialty fittings. For chemical rooms and water treatment blocks, cast bronze elbows—such as 45-degree bronze threaded elbows—can be paired with 300 malleable iron fittings to balance corrosion resistance and cost-effectiveness.

- Fast installation: NPT threads enable quick assembly, ideal for line changes and retrofit projects.

- Versatility: Broad range—elbows, tees, couplings, unions—supports complex routing in tight mechanical spaces.

- Durability: Rugged wall thickness, consistent casting quality, and galvanizing options for harsher environments.

- Interchangeability: Compatible with standard carbon steel pipe and adapters to valves, gauges, and instruments.

Langfang Pannext Pipe Fitting Co., Ltd. brings deep foundry and machining expertise to the sector, supporting repeatable thread performance, smooth internal bores, and dependable sealing. Engineering teams benefit from consistent lot quality, drawings and test data upon request, and flexible production windows aligned with project milestones—key differentiators for OEM and EPC buyers managing timelines and lifecycle costs.

Cost, Maintenance & User Experience

Total cost of ownership (TCO) for Class 300 Pipe Fittings hinges on installation labor, uptime, and maintainability. Threaded systems avoid hot work permits and post-weld QA, lowering labor costs and enabling rapid line starts. For many utility services, Class 300 malleable iron fittings deliver an attractive ROI: they are robust enough for daily operation, simple to reconfigure, and widely available for quick replenishment. The class 300 pipe fittings pressure rating (300 psi at 150°F for malleable iron per ASME B16.3) covers a broad spectrum of plant services while containing capital expenditure compared to heavier classes.

- Lower maintenance: Standard NPT interfaces make inspections, replacements, and expansions straightforward for MRO teams.

- Inventory efficiency: Common sizes (1/4"–4") reduce SKU count and simplify spares management across sites.

- Lifecycle value: Galvanized options extend service life in damp or mildly corrosive environments, enhancing uptime.

Customers in the General equipment manufacturing industry consistently cite the ease of installation, predictable threading, and reliable sealing performance of Pannext fittings as key drivers of user satisfaction. B2B buyers also value Pannext’s dependable lead times and responsive support, which help keep projects on schedule and plants running at target OEE.

Sustainability & Market Trends in manufacturing

Sustainability is reshaping industrial components, including pipeline accessories. Recyclable metals, efficient melting and casting practices, and reduced scrap are now baseline expectations. Many buyers also seek documentation that supports regulatory compliance (e.g., materials declarations, coating specifications) and prefer durable components that extend replacement intervals, thereby minimizing waste. In parallel, market demand is rising for modular, reconfigurable skids and utility manifolds—areas where Class 300 Pipe Fittings and class 300 malleable iron fittings excel due to their speed of assembly and serviceability.

Langfang Pannext Pipe Fitting Co., Ltd. aligns with these trends by emphasizing consistent casting quality, precise machining, and finish options that match the environment—supporting longer lifecycle and fewer replacements. The company collaborates with customers to select the right materials (malleable iron, galvanized finishes, or cast bronze in specific chemistries) and provides technical data to simplify audits and approval processes. As the industry advances toward smarter, lower-emission factories, Pannext’s focus on robust, fit-for-purpose Class 300 Pipe Fittings helps enterprises balance reliability with responsible resource use.

Conclusion on Class 300 Pipe Fittings from Langfang Pannext Pipe Fitting Co., Ltd.

Class 300 Pipe Fittings provide dependable, cost-effective performance for the General equipment manufacturing industry and the Manufacturing of pipeline accessories. With an industry-standard class 300 pipe fittings pressure rating and options spanning class 300 malleable iron fittings and cast bronze components, Langfang Pannext Pipe Fitting Co., Ltd. helps OEMs, EPCs, and MRO teams streamline installation, maintenance, and inventory. Trust Pannext for quality castings, precise threads, and reliable delivery.

- Contact us: email: fanda@pannext-casting.com

- Visit our website: https://www.pannextfittings.com

- Explore product details: 45° Cast Bronze Threaded Elbow

Post time: Nov-10-2025