|

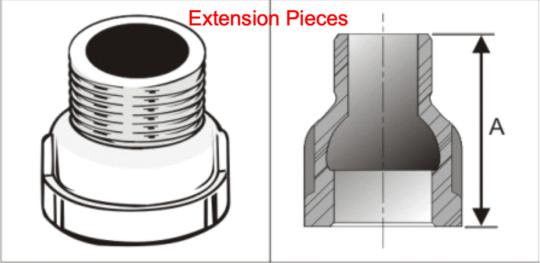

Item |

Size (inch) |

Dimensions |

Case Qty |

Special Case |

Weight |

|||||||||||||||

|

Number |

|

|

A |

|

B | C |

Master |

Inner |

Master |

Inner |

(Gram) |

|||||||||

| EXT05 | 1/2 |

240 |

5/bag |

240 |

5/bag |

88 |

||||||||||||||

| EXT07 | 3/4 |

160 |

5/bag |

160 |

5/bag |

144 |

||||||||||||||

| EXT10 | 1 |

100 |

5/bag |

100 |

5/bag |

228.8 |

||||||||||||||

| EXT12 | 1-1/4 |

60 |

5/bag |

60 |

5/bag |

352 |

||||||||||||||

| EXT15 | 1-1/2 |

40 |

5/bag |

40 |

5/bag |

476 |

||||||||||||||

| EXT20 | 2 |

30 |

5/bag |

30 |

5/bag |

672.5 |

||||||||||||||

|

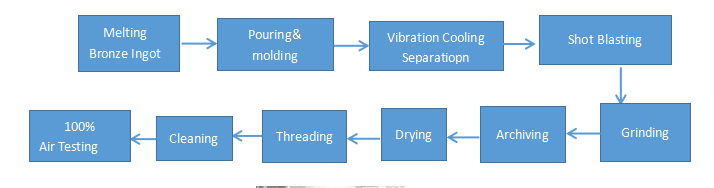

1.Technical: Casting |

6.Material: ASTM B62,UNS Alloy C83600 ;ASTM B824 C89633 |

|

2.Brand:“ P” |

7.Fitting Dimensions: ASEM B16.15 Class125 |

|

3.Product Cap.: 50Ton/ Mon |

8.Threads Standard: NPT conform to ASME B1.20.1 |

|

4.Origin:Thailand |

9.Elongation: 20% Minimun |

|

5.Application:Jointing Water Pipe |

10.Tensile Strength:20.0kg/mm(minimum) |

|

11.Package: Exporting Stardard,Master Carton with Inner boxes Master Cartons:5 layer corrugated paper |

|

We have completely strict quality management system.

|

Every piece of fitting must be inspected under strict SOP whatever from initially raw material incoming to product processing to finished products which are 100% water test qualified before they are into our warehouse. |

1.Raw Material checking,Keeping the Incoming Material Qualified |

| 2. Molding 1).Inspecting the tem. of molten iron. 2.Chemical Composition | |

| 3.Rotary cooling:After Casting, appearance Inspection | |

| 4.Grinding Appearance checking | |

| 5.Threading In-process checking appearance and threads by Gages. | |

| 6. 100% water Pressure Tested, ensure no leakage | |

| 7.Package:QC Checked if the packed cargoes are the same with the order |

Keep every pipe fitting that our Clients’ received is qualified.

Q:Are you factory or trading company?

A:We are factory with +30 years history in casting field.

Q: What terms of payment do you support?

A: TTor L/C. 30% payment in advance, and the 70%balance would be

paid before shipment.

Q: How long is your delivery time?

A: 35 days upon receipt of advanced payment.

Q: lt is possible to get samples from your factory?

A: Yes. free samples will be provided.

Q: How many years the products guaranteed?

A: Minimum 1 years.

NEWS